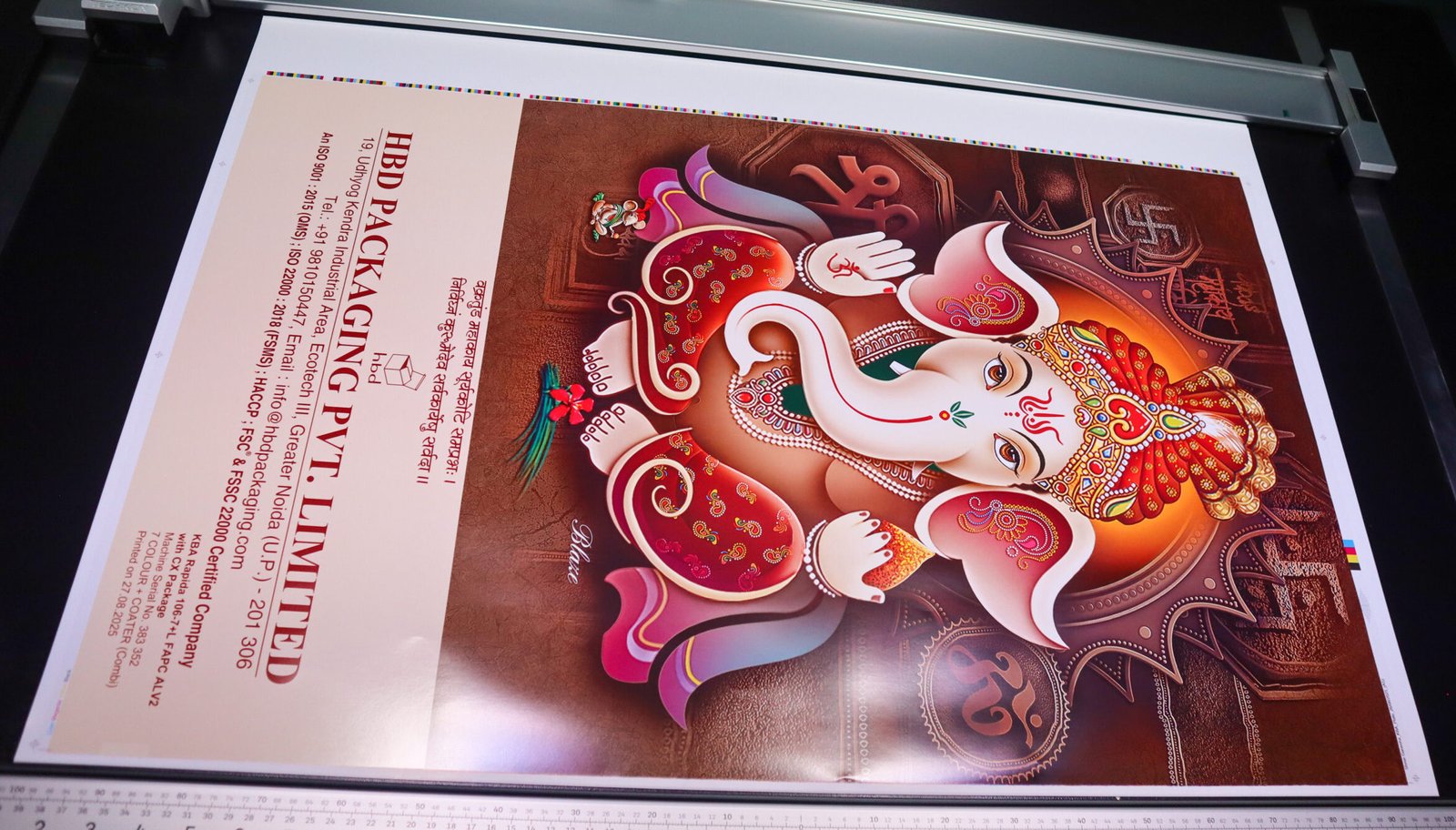

HBD Packaging’s K&B Rapida 106 7-color plus coater UV-ready press arrived within its four-month timeframe and was installed and inaugurated on the occasion of Ganesh Chaturthi on 27 August 2025, accompanied by a ribbon-cutting ceremony and the printing of a testimonial poster featuring Lord Ganesh. The K&B engineers will continue to fine-tune the press setup for formal handover in the next couple of days.

When we wrote in April this year about the press being ordered by HBD, we mentioned that the carton converter based in Greater Noida was in a hurry to expand print capacity as soon as possible, and in time for the Indian holiday season, which includes several festivals, including Diwali, and goes right up to Christmas and the new year. As partners, Rajiv, Sanjay, and Neeraj Bhargav shared after the press inauguration, the opportunity to grow was compelling despite the market being highly competitive with wafer-thin margins.

While HBD has several 6 and 7-color plus coater UV presses running, Rajiv Bhargav suggested in April itself that the slightly larger format Rapida with high automation would help increase the productivity of some of the larger litho–laminated two-piece cartons, which could be moved from 2-ups to 4-ups. At the same time, other carton layouts could go from 4-ups to 6-ups.

“Carton runs are becoming shorter,” he said, “And for this, the automated makeready and plate changing features on Rapida 106 are very important.” Although the press is ready for UV curing, the cassettes or lamps will be imported later.

As we wrote earlier, HBD has grown steadily in the past decade, and at an exceptional rate after the Covid-19 pandemic. Significantly, the K&B 106 7-color plus coater installation and commissioning is taking place only two years after the installation of an RMGT 7-color plus coater LED-UV press. The company has continuously added converting equipment such as micro-fluted corrugation and lamination machines for litho-laminated cartons, and automated foiling, die-cutting, folder–gluer machines. More recently, it added capacity for luxury cartons and an automatic window patching machine with hot creasing.

The carton market is growing, and leading converters need to keep up with the SKUs and volumes of their customers. While margins remain under pressure, HBD enjoys an extremely good reputation for its quality production, attention to detail, transparency in communication, and timely delivery. For a company that believes in growth with its own resources, the new press represents a significant financial investment. Nevertheless, with a firm belief in continuously upgrading technology and automation, the partners felt it was necessary to be in time for the upcoming season, with several customer commitments already in place.

Even as the press is in the commissioning fine-tuning, testing, and tweaking process, the K&B engineers were under pressure to hand it over, as there is a pipeline of work lined up in anticipation of the new press coming into production for the peak season. As Rajiv Bhargav says, “The window of opportunity is small and one must seize it with investments in technology.”