One day before the K-Show in Düsseldorf, industry leaders and packaging print professionals gathered at Allstein’s headquarters in Herford to witness the live demonstration of the first fully automated flexographic workflow shown in public. The event brought together cutting-edge technologies from Allstein, Esko, Kongsberg PCS, and Asahi Photoproducts delivering a seamless end-to-end flexo production run. In the context of an ongoing shortage of skilled labor, the project reflects a broader industry trend: leveraging automation to reduce repetitive tasks and deploy human expertise to higher-value tasks. In Asia where gravure printing is widely used and highly automated, flexo is now catching up through end-to-end automation.

Flexographic Printing 5.0 Comes to Life

Attendees witnessed a fully operational industrial ecosystem – more than a concept or lab setup. They experienced how all partners have integrated their systems to build a seamless, intelligent, and sustainable flexo line. Every step of the print packaging production workflow; from plate imaging, exposure and processing to cutting, mounting, and printing; was automated, showing how Flexo 5.0 is already a reality.

Unprecedented Automation Across the Workflow

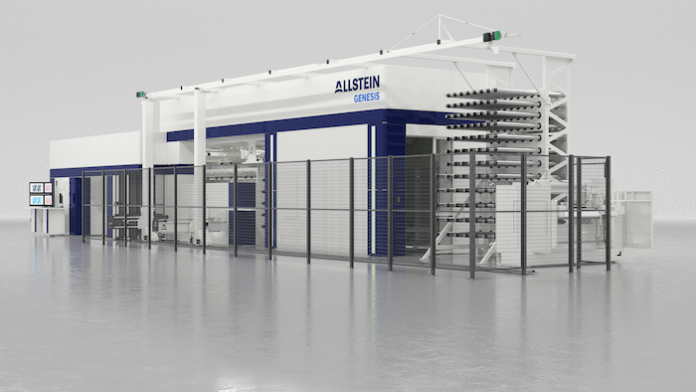

The demonstration included Esko’s CDI Quartz plate imager and XPS exposure systems, Asahi’s CrystalCleanConnect automated plate processor, Kongsberg PCS cutting table, and Allstein’s automatic mounting system and its Genesis flexo press, including sleeve and anilox chamber handling. The integration reduced operator requirements to one. It also brought unprecedented automation and standardization to the workflow. The result: reduced manual intervention and a significant leap forward in industrial productivity.

CrystalCleanConnect simplifies and accelerates plate processing, delivering cutting-ready plates directly to the Kongsberg PCS cutting table for high-precision finishing and less waste. More importantly, CCC has always stood for continuity in the workflow. This demonstration marks not an end point, but a starting point for further integration projects along the flexographic value chain. With multiple CrystalCleanConnect systems already in the market, the partners will continue to connect additional systems and extend automation even further.

A Milestone Moment for Flexo

This event marked the first public demonstration of such a high level of cross-vendor integration and automation in flexo. Attendees praised the line’s clarity, precision, and speed – confirming that flexo automation is now an industrial reality. One of the photographs taken at the beginning of the event was automatically processed during the demonstration, and visitors left with a freshly printed copy produced on the flexographic press.