Sibeg, established in 1960 and headquartered in Catania, is the official bottler of the Coca-Cola Company, based in Sicily. With around 400 employees and eight production lines, ranging from soft drinks to energy beverages, Sibeg handles the production, bottling, distribution, and development of Coca-Cola, Monster Energy products, and Acqua di Tepelene, to over 24,500 points of sale across the island.

Known for quality, innovation, and sustainability, Sibeg aspires to be the ‘gazelle’; the innovation hub and global test site for Coca-Cola’s business units, with a strong focus on Sicilian consumers. Sibeg aims to deliver tailored solutions that meet customer expectations (in terms of product and taste), and serve over 5 million Sicilians, as well as the 7 million tourists who choose to visit the island each year.

Sibeg is targeting zero emissions in Scope 1 and Scope 2 by 2030, and full carbon neutrality by 2032, aligning all investments with this long-term sustainability vision.

In support of these goals, Sibeg recently partnered with Sidel to install a new 18,000 bph complete-aseptic PET line at its site in Catania, enabling the company to bring the production of sensitive products in-house, which were previously handled externally through co-packing.

Reaching sustainability goals

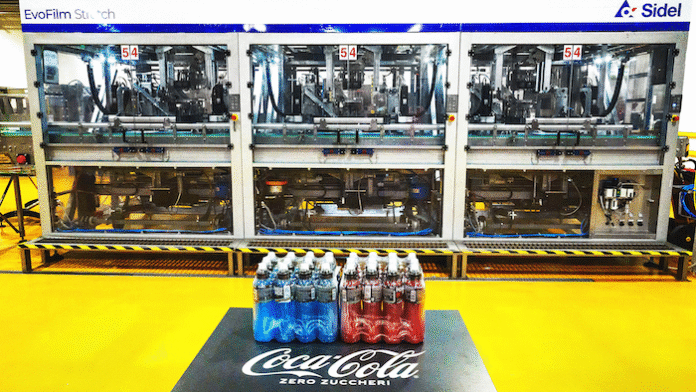

The new line, featuring Sidel’s Aseptic Combi Predis, EvoFilm Stretch, PalKombi machines, and digital solutions, delivers substantial water, energy, chemical, and plastic savings, reinforcing Sibeg’s commitment to sustainable and efficient operations.

Furthermore, the 100% rPET production allows Sibeg to reduce the environmental impact, contributing to a circular economy and minimising waste.

Luca Busi, CEO at Sibeg, comments: “This move reflects our strategic effort to both expand our product portfolio and enhance flexibility in meeting customer demands, while also cutting down on pollution from truck transport from Northern Italy, further reinforcing our commitment to sustainability.”

“Sidel and Sibeg share a long-standing partnership, with a complete line previously supplied for CSD packaging. Once again, Sibeg places its trust in Sidel, this time for aseptic production, relying on its well-known expertise to ensure the highest levels of product safety. The complete aseptic PET line will enable us to diversify into energy drinks and tea production.”

Aseptic complete solution

Sibeg chose Sidel as the only vendor for the entire supply due to the proven expertise in aseptic packaging.

“We felt safe relying, especially from a technical point of view, on a partner who is widely renowned for mastering the PET aseptic packaging production. Moreover, the collaboration with Tetra Pak for the processing part enabled us to cover the entire production process, from beverage preparation to the packaging line with a single contact point, bringing a strong increase in efficiency during execution,” adds Gianluca Tornatore, Operations Director at Sibeg.

Transformative complete aseptic line

Sidel has delivered a complete aseptic PET line featuring the Aseptic Combi Predis, which seamlessly integrates preform sterilisation, blow moulding, filling, and capping into a single process. This ensures product integrity and extended shelf life for sensitive beverages.

The system is renowned for its dry preform decontamination using a hydrogen peroxide mist, which drastically reduces water and chemical usage, supporting Sibeg’s sustainability goals while aligning with evolving consumer preferences. It ensures complete product safety without the use of preservatives and successfully passed on the first attempt the aseptic validation protocol, complying with the Coca-Cola company standards.

Designed for ease of use, the Aseptic Combi Predis allows operators to manage the sterilisation process economically, minimising downtime and reducing the need for extensive training. The system also offers exceptional flexibility, allowing Sibeg to switch between ten different formats from energy drinks to teas, while maintaining the highest levels of food safety and productivity.

EvoFilm Stretch – breakthrough stretch wrapping technology

Sidel also installed its EvoFilm Stretch packer, a breakthrough in stretch wrapping technology that boosts environmental performance and operational efficacy. Unlike traditional shrink-wrapping, it works at ambient temperature, eliminating the need for energy-heavy shrink tunnels. This cuts plastic use by up to 60% and reduces energy consumption by as much as 90%, helping Sibeg to save costs while reaching sustainability goals.

“Using high pre-stretch LLDPE with a thickness of 10 to 23 microns, EvoFilm Stretch allows automatic sealing and flexible wrapping options. It lowers plastic use from 26 gram to 6 grams per pack and energy use is only 10 kWh, leading to a 90% savings compared to traditional shrink-wrapping solutions,” says Gianluca Tornatore, operations director at Sibeg. “Without shrink tunnels or conveyors, it also minimises machine footprint, making packaging lines more compact and cost-effective.”

Intelligent software – Evo-ON Flex

Sibeg also opted for Sidel’s Evo-ON Flex app – an intelligent software that streamlines the bottle change-over process by guiding operators step-by-step through each required action. It provides a comprehensive, real-time overview of all scheduled changeovers for the entire work shift, boosting operator adeptness, and eliminating potential downtime.

“The Sidel team were deeply committed to meeting our needs and timelines at every stage, from line design to ramp-up, while navigating the challenges of meeting Coca-Cola’s stringent safety standards. Their dedication ensured a smooth process without compromising on quality or compliance,” commented Gianluca Tornatore, operations director at Sibeg.