The HP stand at Labelexpo in Barcelona was always busy, with several new presses demonstrated at the show, and a continuous flow of both Indigo owners and potential customers looking at the company’s latest innovations. The innovations marked a step up from the previous paradigms of what an Indigo digital press can do. Repeat customers from India were notably active at the show – in some cases discreetly buying new presses such as the Indigo 6K+ digital press, shown at Labelexpo Europe for the first time. And in other cases, such as Spectalpack announcing and celebrating its multiple repeat orders for the Indigo 200k flexible packaging and labels, which was also shown running.

solutions, HP Industrial Print APJ.

Photo- PSA

At the HP stand in Barcelona, we had the opportunity to meet Yoav Lotan, head of Products and Solutions for HP Industrial Print, in the Asia-Pacific and Japan region. Lotan, who is based in Singapore, emphasized the importance of the Indian market to the company and also gave us a step-by-step guided tour of the new HP Indigo V12 press being demonstrated live at the show.

An important learning from our meeting with Lotan was that the latest versions of Indigo technology, such as the 6K+ digital press and the V12 demonstrated at Barcelona, still have plenty of headroom in speed and efficiency. This means that for many label and packaging converters, especially those who are already HP customers, with the latest iterations of the Indigo technology, such as LEPx imaging, there is no compelling need to jump from liquid toner to inkjet presses.

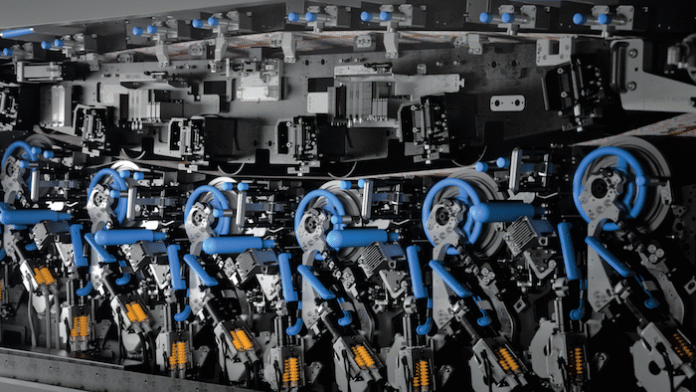

As Lotan took us from the infeed to the delivery, what came across was HP’s major engineering feat in placing and configuring twelve ink supplies in a row, with pairs supplying to six drums and a much longer belt that receives the inks for transferring the composite image to the substrate. When the 12 ink supply units function as six pairs for 6-color printing, the 1600 dpi LED writing heads image the drums at twice the speed, which transfer the ink to the long belt running in a loop for printing the image to the substrate at 120 meters a minute.

Using the 12 units for as many colors slows down the printing speed to 60 meters a minute, as each LED imaging head has to charge the drum for two colors. From the infeed unwinder, the substrate goes to a buffer which absorbs the shocks to the moving web from stopping, starting, or changes in speed for so that the imaging can take place with precision. A primer station prepares the substrate for optimal electroink transfer, which is monitored by an inline closed-loop color quality system.

press.

Photo- PSA

Lotan described HP Indigo’s India strategy, beginning with the photo and photobook industry, and that went on to success with label customers. “We now have label customers with multiple installations, and also some customers for board packaging. And then we have established flexible packaging converters who have migrated to our 200K flexible packaging and label presses. In some ways, India is a unique market where we are finding more agility in the smaller businesses and SMEs. There are many young entrepreneurs with new ideas, and so we are seeing a creative migration to digital flexible packaging in India.”

Describing the HP Indigo stand at Labelexpo Barcelona as tech-affirming and one of strong conviction, Lotan said the new 6K+ offers smarter control and more reliability, while the V12 offers a strong option for label converters. He spoke about HP’s Print OS and the importance of its new generation AI capabilities in handling inline data, “How to use data is key,” he said, adding, “In the future, everyone will have two factories – one for production, and the other for data.”