Mumbai-based Swastik Enterprises offers high-end finishing effects to meet the demands of Print Service Providers (PSPs), FMCGs and the garment industry with velvet, drip off and spot UV finish. Shrikant Bhosle, owner at Swastik Enterprises, believes that apart from making the pack splendid, special effects add to the branding proposition and provide protection against any counterfeiting activity. Speaking to Packaging South Asia, he states, “It may look like huge investment in terms of capital and certainly it is an option that has worked well for a few printing companies, though adding value does not have to involve large amounts of investment. In fact, many printing companies already have inhouse value-added solutions. Our intention is to create well-finished products within the allotted time and deliver as promised. We intend to draw emotion than simply going about doing our job. Our prospects are ready to pay more for the right product.”

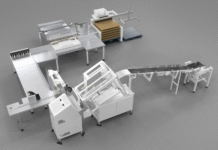

Located in Shah and Nahar Industrial Estate, well known as the hub of printers in the western region of Mumbai, Swastik Enterprises initiated its journey in postpress services in wiro binding, which still runs at the unit. Over a period, due to shrinking volumes in commercial, Bhosle expanded their services in carton packaging and at present finishes around 30,000 sheets a day. Recently, the company installed a 5-color Komori Lithrone 528 EH press with double coating units.

Located in Shah and Nahar Industrial Estate, well known as the hub of printers in the western region of Mumbai, Swastik Enterprises initiated its journey in postpress services in wiro binding, which still runs at the unit. Over a period, due to shrinking volumes in commercial, Bhosle expanded their services in carton packaging and at present finishes around 30,000 sheets a day. Recently, the company installed a 5-color Komori Lithrone 528 EH press with double coating units.

Enterprises

According to Bhosle, there is a rise in demand for printed Metpet cartons and Swastik focuses on improving quality as well as productivity with with the recent installation. In addition, the compact size of the press fits well in the gala space. At Swastik, the machine is run at a speed of 10,000 sheets an hour; the maximum speed it can run is 15,000 sheets an hour.

Swastik Enterprises production unit has six galas containing a battery of screen printing presses, paper cutting and offline varnish machines spread across 10,000 sq. ft of the production floor. Further, Bhosle plans to retrofit the press with LEDUV drying system and install an offline varnish inspection system shortly.