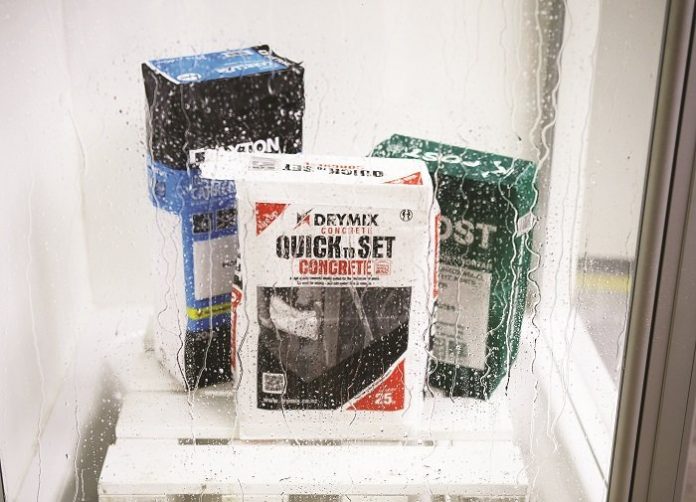

Paper valve sacks with a high degree of moisture protection are a strong packaging trend globally. While paper usually comes on top of all other sack materials when it comes to sustainability, plastic sacks are popular due to their high level of moisture protection. New concepts combining the benefits of a paper sack with increased moisture protection are therefore in high demand at the moment. The challenge lies in meeting individual market requirements of the sack as best as possible while also ensuring that the production is economically efficient.

To ensure a high level of moisture protection, various approaches can be applied or even combined. Ideally, a new sack concept should combine the relevant market requirements with maximum production efficiency.

Once the final sack design has been selected, paper sack converters need to

rely on high-quality production, and hence the need for the right technology.

Based on the design, this may depend on the finish of the film layer, for instance,

or the application of the glue in the tuber and bottomer. And of course the right

equipment in the patch units are also needed.

Almost 100 years of experience in the paper sack market

Ever since the valve sack was introduced almost 100 years ago, Windmoller & Holscher has been producing paper sack machines. Nearly all moisture-protected paper sacks in the European market are produced on its machinery. The company aims to merge an economically efficient production process for paper sacks with individual market and product requirements for the sack. At its inhouse technology center and lab, W&H has tested an array of concepts for their performance and effects on the production process.

In India, W&H is a leader in the woven sack segment, a solution which is growing for because of its robustness given the local logistics requirements. However, with the increasing legislative concerns around the country on packaging sustainability, there is significant interest in paper-based sack solutions. The company is ready with appropriate technology for paper sack solutions that meet the needs of many applications.