General Air Products has partnered with Cortec Corporation to develop a vapor phase corrosion inhibitor delivery system to tackle corrosion in fire sprinkler systems. Robust firefighting systems are crucial to flexible packaging plants that are prone to fires. A major fire in a plant of Jindal Poly Films at Mundhegaon near Nashik claimed three lives on 1 January 2023.

General Air Products calls this new vapor pipe shield a ‘game-changing innovation in corrosion prevention technology for dry pre-action fire sprinkler systems.’ Cortec says facility engineers and consulting engineers can apply the benefits of the technology to critical fire suppression systems.

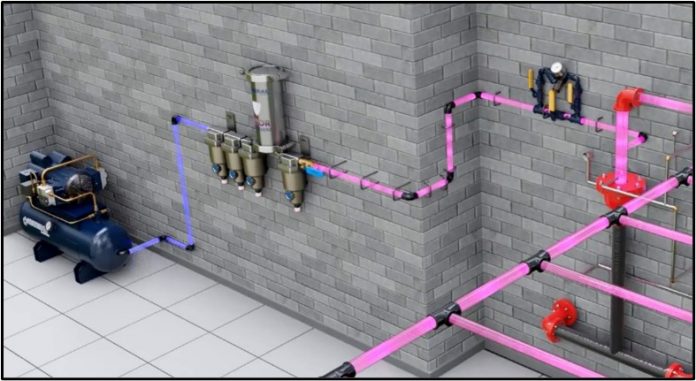

The Vapor Pipe Shield is said to be a more dependable alternative to nitrogen blanketing or dried air for the protection of fire sprinklers against corrosion. It relies on Cortec VpCI technology—vapor phase corrosion inhibitors that create a protective molecular shield on the inside of the sprinkler piping system. No special equipment is required; the cartridge is compatible with standard sprinkler setups and is easy to install between the air compressor and the piping.

Compressed air initially helps the vapor phase corrosion inhibitors diffuse throughout all branches of the piping system to form an active layer of protection on metal surfaces. Since these vapor phase corrosion inhibitors continue to protect as long as the system remains closed, corrosion mitigation does not depend on a constant source of electricity. That means a failed air compressor, nitrogen generator, or power source does not equal failed protection or require complete reapplication. Vapor phase corrosion inhibitors also protect in the presence of residual moisture and oxygen.