Zecher’s webinar on 15 April 2021 had quite a bit of helpful content for flexo printers. Meant for savvy users of flexography, it presented several ideas that, if combined, can save printers considerable money and at the same time improve their quality.

The webinar showed the range of Zecher products and services. It discussed how adopting one, and preferably several options available from the company could considerably reduce the cost of tooling for flexible packaging and label printers.

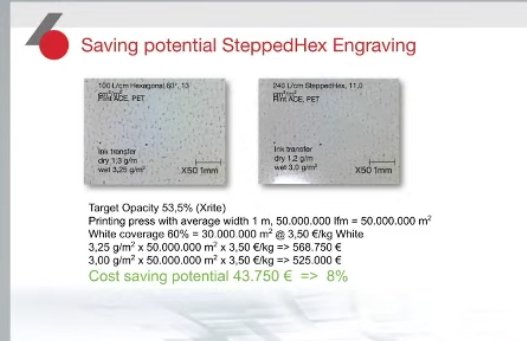

The Zecher colleagues Sven and Svetlana said that, in general, huge savings could be made by reducing the number of anilox rollers that a plant buys, uses, maintains, and cleans. “Printers have too many anilox rollers,” they said. They introduced the company’s HIT aniloxes with open-cell volumes, and its Stepped Hex engraved anilox rollers that can save up to 5% in ink.

They showed a typical list of rollers that a flexographic printer might have and how as an example, this number can be reduced from 30 to 22 anilox rolls. A vital benefit of the Zecher technology is that its rollers are plasma-treated, which improves ink transfer across a variety of image saturation.

The webinar then proceeded to the Windmoeller and Holscher demonstration center in Lengerich. Zecher anilox sleeves were used to demonstrate a difficult flexible printing job with a gold halftone and solid but produced using just using CMYK units and a spot color brown on one more unit of the W&H Miraflex CI flexo press. The Kodak Flexcel NX flexo plates were provided by one of the leading German prepress suppliers.

The event was interesting for those who are keen to refine their practical technical knowledge of flexography and the use of various types of anilox rolls. The presenters spoke about Zecher’s refurbishing service for anilox rolls. And interestingly pointed out that they can re-engrave the old anilox rollers with some of the new cell formations and treatments. The laser cleaning of anilox rolls was discussed as the ultimate way of performing this necessary task. It became clear that tooling is one area that can help to improve quality and ease of operation while also controlling overall costs.