Super Plastic Coats, a long-established supplier of packaging films, has established a Greenfield manufacturing project to produce cast polypropylene film. Located in the Industrial Growth Centre Phase II in Samba District, Jammu and Kashmir, the 80,000 square foot plant was initiated in the previous financial year, and the new film line and metallizer have gone into production in the first quarter of this financial year.

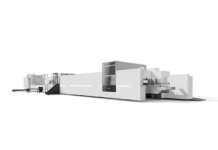

The investment and commissioning of the new Cast Polypropylene (CPP) line, together with a K5 metallizer with Alubond capability, reflects the company’s commitment to high-performance barrier films and advanced flexible packaging solutions. The 7-layer W&H Filmex II line, with its unique screw design, provides excellent melt quality for all types of resins, an integrated continuous dosing system, and efficient chill roll technology. The line is equipped with W&H’s Die Control Wizard (DCW) system, a highlight of the new setup for the fastest and most reproducible profile control.

Since over 90% of the CPP lines in India have a 3-layer or 5-layer structure, a 7-layer line gives SPCPL a significant competitive advantage. The 7-layer structure enables it to use various polymers and develop highly customizable and functional structures. It also helps in the form of enhanced barrier properties and improved mechanical strength in the film. In addition, the line comes equipped with W&H’s Ruby system for monitoring through dynamic data sampling, and enhanced data collection for future product optimization and enabling the company to maintain the highest standards of quality.

The plant in Jammu is built to provide high-barrier CPP films of exceptional quality and precision. Enhanced barrier properties are enabled by the 3.65-meter-wide Bobst K5 Expert metallizer with Alubond. Apart from enhanced barrier properties, the Alubond technology provides a very high dyne level retention and high bond strength.

The slitter-rewinder is provided by J Kampf, and the extensive on-site laboratory contains Mocon OTR and WVTR barrier testers, RDM COF and hot tack testing equipment. There is a Lloyd UTM for mechanical tests on films, including tensile, compression, and a Tobias optical density tester for evaluating the optical properties of the films produced. Dart impact and heat-seal testers are also provided in the lab.

The entire project is built for the highest quality CPP barrier films produced with precision for specific applications, including flexible packaging for food products designed to provide high levels of shelf life as well as sustainability. In this respect, it is an exceptional plant within the country meant for developing high barrier applications needed by brand owners that are committed to delivering high–quality products and sustainable packaging, and compliance with the Plastic Waste Regulations as well. For a company that has specialized in the trading of packaging films, including BOPET, BOPP and CPP films for over 25 years, it underscores an ambition to shape the future of flexible packaging.

“This investment reflects our long-term vision to offer high-performance and sustainable packaging solutions in the Indian market and beyond. With W&H’s FILMEX, we now have the precision and flexibility to meet our customers’ evolving needs. We trust that our W&H line will deliver the highest quality CPP films available in the market today. As we continue to evolve and innovate, this project marks a significant milestone in our journey, enabling us to offer even more advanced, sustainable, and customized solutions directly from our state-of-the-art production facility,” says Praveen Bansal at Super Plastic Coats.