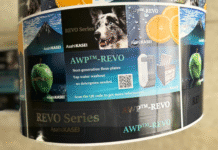

Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, reported that a leading Chinese label printer has switched to Asahi CleanPrint AWP flexographic plates from their standard thermal plates following extensive comparison of the two plates running live jobs with UV ink. The company reported OEE improvements of 46% for some jobs, with an average improvement of 21%.

Asahi CleanPrint plates need a one-time cleaning

The jobs ranged from typical four-color label printing to more complex seven-color jobs with screen printing and foil. In an extreme case, with a four-color job, the press running competitive plates stopped for plate cleaning 24 times at about three minutes per event. The press running the Asahi plates only required plate cleaning once due to the characteristics of Asahi’s CleanPrint plates.

In the flexo industry, Overall Equipment Effectiveness, or OEE, is a measurement of the performance of a printing press. It’s calculated as – OEE = Availability x Performance x Quality, which delivers an OEE percentage. It’s a fact-based way to measure the efficiency of your operation and identify ways to improve it over time continuously.

“We found the results of these tests to be quite interesting,” said Ryo Ichihashi, general manager of Asahi Kasei Electronics Materials (Suzhou) technical center. “and inline with our overall industry experience. In the case of this label printer, the quality delivered by the two plates was roughly the same, but availability and performance were significantly improved with the Asahi CleanPrint AWP plates. This means that the company will now be able to produce an average of 21% more work in their shop with an equivalent quality, which translates to a significant profit boost.”

The company’s chemical engineers have specifically developed CleanPrint flexographic plates from Asahi Photoproducts to transfer remaining ink to the printed substrate, reducing press stops for plate cleaning while delivering exceptional, consistent quality throughout the entire run. This results in higher quality, less waste, and improvement in OEE, as clearly demonstrated by this Chinese label printer’s comparative study.