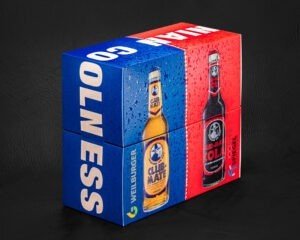

Showcasing a sustainable alternative for food packaging – that was the aim of the new demo project by Weilburger Graphics. The company created an innovative and recyclable beverage cooler made from paperboard and using a completely new waterproof coating. For the material, they chose Metsä Board’s, part of Metsä Group, lightweight, fresh fiber paperboard. The packaging comes with a cooling tray, and that can take up to 500 grams of crushed ice or cold water. MetsäBoard Prime FBB EB eco-barrier paperboard was used with Weilburger Graphics’ new Senolith water-based barrier coating to keep the water inside the cooler.

“Many of our customers, especially in the food, cooling, and frozen food sectors, are looking for environmentally friendly packaging solutions that are also safe for direct food contact. Often these solutions need to be waterproof,” says Arno Dürr, Sales director at Weilburger Graphics GmbH, an international coating, flexo inks, and adhesive manufacturer based in Germany.

The main body of the box, including a bottom and a cover, was made of MetsäBoard Classic FBB 340 grams per square meters, while the special cooling tray, as well as the compartment separator for easy fill-up was made of Metsä Boards eco-barrier paperboard MetsäBoard Prime FBB EB 265 grams per square meters.

“Both the idea and the implementation turned out very well. The result was a sustainable alternative to conventional packaging methods, which also has an impressive feel and look. In the future, this kind of package might be an option also for fresh fruit and other foods that need to be chilled,” says Gabriel Goldmayer, Account director at Metsä Board.

Fresh fiber paperboards usually tolerate humidity better than recycled fiber-based grades. They are also lighter, and therefore enable a lower carbon footprint of the packaging. After use, they are recyclable, contributing hence to circular economy.