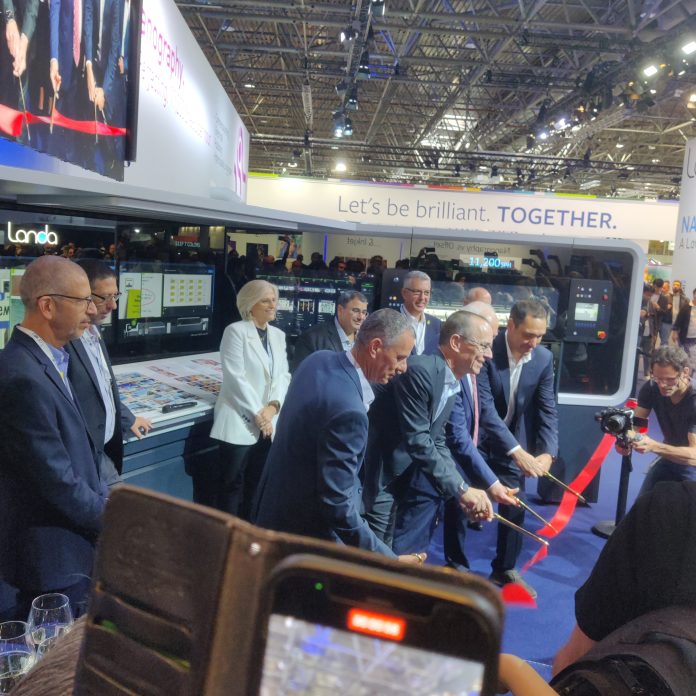

On 28 May 2024, the opening morning of drupa, Landa returned with Nanographic B1 format presses that finally seem to deliver quality that approaches analog processes at reasonably acceptable speeds that could drive higher volumes and thereby bring the economics of high-quality digital printing within the thinking of some part of the carton market. Over 50 Landa presses are now installed in 14 countries – with more than 20% of the customers having placed a repeat order for a second or third press.

Landa also demonstrated the Nanographic process itself on a simple handfed rig from its labs. For its improvements and evolution, the process continues to rely on the fundamental science of color and its transfer to various substrates. The most impressive part of the demonstration was that it entails the transfer of a fully cured complete image leaving no trace on the transfer belt or with any part of the ink seeping or showing through a variety of substrates including newsprint.

High-quality samples on various substrates ranging from coated stocks to newsprint are displayed at the stand. The overall quality has greatly improved from eight years ago, as indicated by the purchase announcement at the press conference of the technology by one of the largest commercial printers in the world who was waiting for it to match his requirements. This indicates the correct discriminatory approach to buying a Landa press – if it fully matches your color quality reproduction requirements and economics, then go for it.

It’s claimed that the new PrintAI module delivers high-fidelity precision print, using artificial intelligence. The new S11 and S11P models include a new ink drying system that enables the transfer of dry ink from the blanket to the media, at the higher speed of 11,200 sheets an hour. In addition, new Landa modules enable the S11 and S11P presses to be customized to exact customer requirements.

Commercially available at Drupa 2024, the new Landa presses will also offer the new PrintAI module, for enhanced print quality claimed to be fit for demanding folding cartons and commercial print applications requiring micro text and other brand protection features. The new Landa models are claimed to enable printers and packaging converters to not only increase print quality but also elevate productivity and profitability while further reducing job turnaround times.

Press customization

The new Landa S11 and S11P can be customized to the exact requirements of each customer. Each new press comes with a choice of four or seven colors, a continuous printing capability, an optional in-line coating unit, and the opportunity to purchase the 11K Module elevating productivity to 11,200 sheets an hour and/or the PrintAI module.

Landa, although chastened by having to go back to the drawing board several times over the past 20 years, remains ebullient in his love for print and for tackling the challenges he creates for himself with more science and its practical learnings that go into building robust and economical solutions. His potential customers keep driving him to higher quality levels that will eventually meet their specific needs at first, and then hopefully, meet an extremely high universal standard without compromises. Also exciting was his statement that the next project for Nanography is to take on flexible packaging.