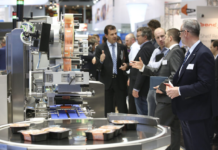

Coesia, a global leader in industrial and packaging automation, will showcase a strong line-up of solutions at Fachpack 2025, taking place from 23 to 25 September at Nürnberg Messe (hall 3C, stand 230).

A highlight will be the introduction of Coesia company Norden’s new NC100 cartoner, reinforcing the company’s leadership in advanced tube filling and packaging solutions. Visitors will discover how Coesia companies are advancing automation across consumer, healthcare, and industrial sectors with scalable and sustainable systems. Experts from FlexLink, AMACO, Norden, and Volpak will be present at the booth, showcasing technologies that enhance efficiency, flexibility, and long-term value creation.

NC100: Compact efficiency and customer-focused design

Norden’s newly launched NC100 cartoner is designed to maximize operational efficiency and flexibility in pharmaceutical, personal care, food, and consumer packaging environments. Handling up to 100 cartons per minute, the NC100 offers fast and repeatable changeovers with up to 50 pre-programmed formats accessible at the touch of a button. Ergonomic material loading, intuitive EasyWare II software, and a 10-inch touchscreen HMI simplify daily operations and reduce training requirements, ensuring optimal user experience.

Built on a balcony-type design for easy access and cleaning, the NC100 combines mechanical robustness with servo-driven precision. Its flexibility extends to carton erection, leaflet insertion, coding with inkjet or laser, and multiple carton closure options, delivering both functional and tamper-evident packaging. OCR/OCV and barcode scanning can be integrated to ensure compliance with demanding pharmaceutical standards. These features translate directly into economic advantages for customers: reduced downtime, lower operating costs, faster format adaptation, and consistently high product quality throughout the machine lifecycle.

NM902: Master of adaptability

Alongside the NC100, Norden will present the proven NM902 tube filler, capable of handling up to 100 tubes per minute across a wide variety of materials, including plastics, laminates, metals, and sustainable mono-materials. Its flexibility enables options like swirl or three-color filling, while its clean design makes it suitable for cleanroom environments.

Serving industries such as personal care, pharmaceuticals, healthcare, chemicals, food, and home care, the NM902 delivers high efficiency and reliability, giving manufacturers the ability to adapt quickly to new market and sustainability requirements. Together, the NM902 and NC100 form a complete line that combines speed, adaptability, and automated precision. This setup enables manufacturers to achieve higher throughput, minimize waste, and reduce total cost of ownership.

“Norden’s mission is to help our customers achieve the highest efficiency with the lowest total cost of ownership,” says Magnus Nilsson, area sales manager at Norden. “With the NC100 and NM902 working together, manufacturers gain the flexibility to adapt to multiple formats, the speed to increase throughput, and the reliability to reduce downtime. This combination gives producers real competitive advantages in fast-changing markets.”

FlexLink: Smart palletizing for dynamic warehouse operations

FlexLink will present its RC12 Re-Palletizing Line, an advanced system designed to streamline pallet handling in warehousing and co-packing. By integrating two collaborative robots, the RC12 enables seamless automation of pallet size and pattern changes, which is particularly valuable when orders need to be repacked or adapted to different configurations. With the intuitive RobotConfig interface, operators can program new pallet patterns quickly and easily, without specialized expertise.

The RC12’s movable design, free from fixed floor attachments, delivers flexibility for dynamic warehouse environments while saving more than 50% of the floor space compared to conventional palletizing systems. FlexLink robotics solutions, powered by advanced software and optional intelligent algorithms, can handle increasing complexity and mix different formats for heterogeneous shipments. This includes AI-driven, on-the-fly mixed palletizing that adapts instantly to dynamic shipment requirements, boosting operational agility.

AMACO: Late-stage customization for medical packaging

AMACO will focus on its MEDJET printers, an advanced drop-on-demand inkjet system that enables flexible late-stage customization of medical device packaging. With high print quality even on rough surfaces, low operating costs, and minimal downtime, the MEDJET PULSE and FLOW offers manufacturers a scalable solution for UDI compliance and on-demand printing, supporting both regulatory requirements and leaner production.

Volpak: Expertise in pouching technologies

While not physically showcasing equipment, Volpak will be represented at Fachpack to discuss its leadership in flexible packaging. With expertise in horizontal form-fill-seal (HFFS) pouching and a commitment to sustainable formats, Volpak continues to support industries seeking consumer friendly and eco-conscious packaging solutions.

A recent example is FlexoDose Light: a next generation inverted pouch with a lightweight mono-material polyethylene structure and a spill-proof cap, designed to reduce carbon footprint while offering clean, precise dispensing down to the last drop. Suitable for applications across food, personal care, and home care, FlexoDose Light provides a versatile, fully recyclable alternative to rigid packaging, fully compatible with Volpak’s SI and SP HFFS platforms.