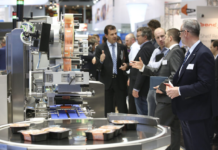

Anantshree Chaturvedi, vice chairman and chief executive officer, Flex Films International believes the industry is headed for consolidation beginning 2018-2019. “When the going was good it did not matter but now that the market conditions are unfavorable, the return they [new players] got back then is not there anymore. As time goes by and low price conditions continue, the companies whose core business is not films will eventually look to consolidate. We are definitely headed towards that. I thought this would have happened a couple of years earlier,” said Chaturvedi while talking with Packaging South Asia at Flex

Film’s stand in interpack 2017. He added that manufacturers still adding lines in places like India, Pakistan, Southeast Asia and even in the US despite the low prevailing prices and the existence of so much capacity is just not viable.

Flex Films is the global film manufacturing arm of India’s largest multinational flexible packaging materials and solution company Uflex Limited. Flex Films manufactures biaxially oriented polyester (BOPET) films, biaxially oriented polypropylene (BOPP) films and cast polypropylene (CPP) films, speciality and metallized films. The company operates state-of-the art manufacturing facilities in India, UAE, Mexico, Egypt, Poland and the USA.

Moving towards specialized products

A result of the low price and oversupply situation is that companies are now moving away from commodity films to speciality films. “Margins have come down to such a level that commodity films do not seem to have a bright future for a few years at the least. So, everyone is moving towards speciality films. I believe, in all this, the key to be a winner in this race will be the way in which companies execute their strategies in the smoothest manner and who will continuously innovate and create new products for the customers,” Chaturvedi argued.

A result of the low price and oversupply situation is that companies are now moving away from commodity films to speciality films. “Margins have come down to such a level that commodity films do not seem to have a bright future for a few years at the least. So, everyone is moving towards speciality films. I believe, in all this, the key to be a winner in this race will be the way in which companies execute their strategies in the smoothest manner and who will continuously innovate and create new products for the customers,” Chaturvedi argued.

Flex Films is in the midst of a transition from commodity films towards having a focused portfolio of speciality films. Some of the highlights of Flex Films’ speciality products at interpack were a digital printing (PDP) polyester film, which is a recently HP Indigo certified substrate suitable for direct digital printing without requiring any priming or coating. Another was a special polyester film that has replaced BOPA and PVC substrates from a typical Alu-Alu laminate for pharmaceutical packaging.

Chaturvedi stated that these days the holy grail for all film manufacturers is high barrier films. “The higher the barrier that you can achieve the more you can claim that your film is special and unique, whether you achieve it by coating or by changing the masterbatch or whatever way. There is a huge demand for this film and the demand will continue to grow as consumers in developed markets like Europe and US now demand less packaging,” he informed.

Expansion in Poland

Flex Films supplies its European customers from its film manufacturing plant in Poland. The plant has a state-of-the-art 8.7 meter wide BOPET film line that runs at 500 meters a minute with a monthly designed capacity of 2,500 metric tons. The plant was commissioned in 2012. “I can tell you that most likely the next expansion in the group’s film business will be the second line in Poland. When will we take that step? How will we take that step? Will we put a PET line or OPET line? All this is too early to say. However, I want to repeat that there is room for a second line and Poland is doing well enough to get that,” Chaturvedi said.

Finally, taking about some trends in the European market, he commented that digital printing is gradually becoming a reality in Europe. Anything to do with short-run and quick turnaround time is utilizing this technology; products which are seasonal or which need continuous promotion or organic foods are ideal for digital printing. Another trend he mentioned was that sustainability is back on the table in Europe. “The topic was dead for the last couple of years but now there is a return to pursuing green polymers. Players are serious about it and do not want to do it just for the sake of talking about it,” he said.