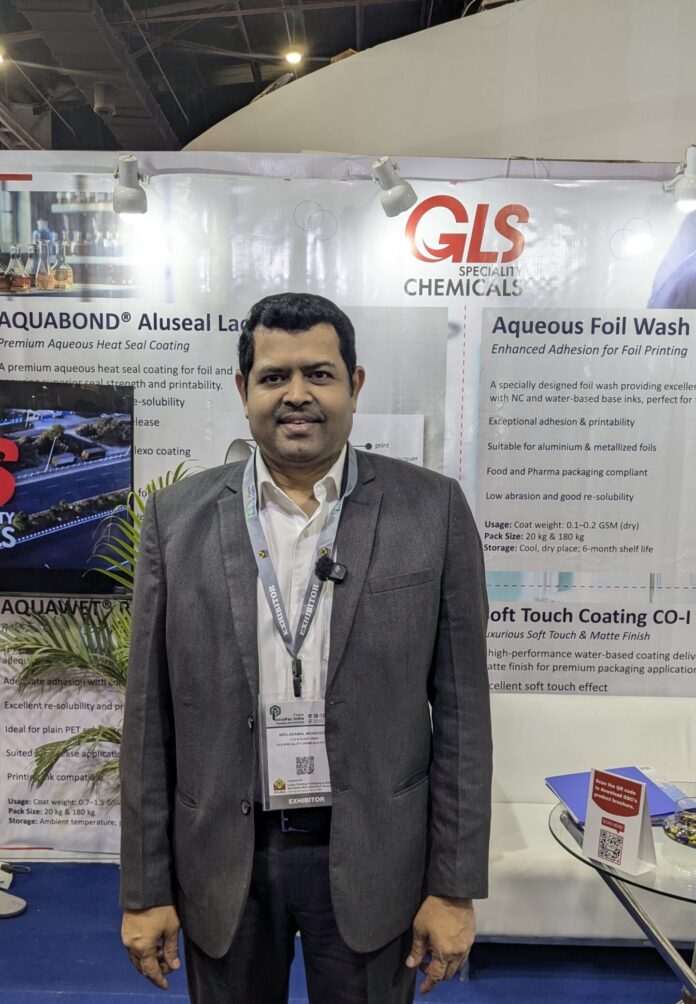

At the second edition of the IntraPac India exhibition, GLS Speciality Chemicals is highlighting its water-based inks, VOC-compliant inks, and high-performance lamination adhesives. Speaking at the company’s stand, Neelakamal Mohapatra, CTO and plant head, GLS Chemicals, shared insights into GLS’s innovation-driven product portfolio and the growing industry demand for sustainable, regulatory-compliant solutions.

Participating for the first time at IntraPac, GLS reported excellent footfall, with interest coming not only from Indian converters and printers but also from overseas visitors and leading brand owners. Mohapatra said the enthusiasm was primarily driven by the company’s circular economy-oriented and sustainable products.

According to Mohapatra, the highlighted solutions have become ‘hero products’ for the company, addressing both environmental considerations and high productivity requirements of modern converting operations.

GLS is strongly promoting its Pureflex ink series, which Mohapatra described as a breakthrough in sustainable ink technology. “With toluene now banned in India and amid a rising need for toluene-free and ketone-free printing solutions, Pureflex offers converters a viable, high-performance alternative,” Mohapatra said.

The ink series runs at speeds of 450 to 500 metres per minute, providing excellent print quality while meeting stringent regulatory and food safety norms. Stating its role in enabling cost optimization without compromising quality, Mohapatra emphasized it to be an innovative product from GLS’s portfolio.

As most of GLS’s offerings are for food packaging, the company remains focused on delivering solutions that balance performance, compliance, and cost-effectiveness—three critical challenges faced by both converters and brand owners today. Mohapatra explained that customers are increasingly seeking materials that meet Indian and global regulatory standards while supporting sustainable transitions within their packaging lines.

He said GLS is witnessing a rising demand for speciality coatings, particularly as the industry shifts from plastic to paper structures and from multi-layer to mono-layer packaging. To support this evolution, the company has introduced barrier coatings and other speciality functional coatings tailored for new-age packaging formats.

Looking ahead to the three-day exhibition, Mohapatra expressed optimism about connecting with converters and brand owners who are eager for innovation and collaborative development. “We want them to challenge us with new ideas,” he said.