Husky Technologies has used drinktec 2025 in Munich as the global stage to reinforce its commitment to “sustainability without compromise,” unveiling its next-generation HyPET6e 200-cavity platform, new closure innovations, and expanded digital monitoring solutions.

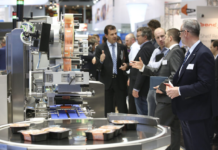

Speaking before a press tour of Husky’s stand in Hall C5, CEO Bradley Selleck underlined the company’s holistic approach. “It’s about how you design the package, the machine, and the overall product as part of one ecosystem, then monitor it globally to ensure efficiency, less waste and better quality,” he told the attending media.

The press tour highlighted Husky’s live demonstration of a 200-cavity mould system, run by operators from Luxembourg and Canada. The system achieves a 5.6-second cycle time, producing 130,000 preforms per hour — faster than any existing filling line. It also incorporates new vacuum drying technology that the company described as “revolutionary” for enabling higher rPET processing with lower energy consumption. Husky reported that the system consumes 13% less energy than last year’s best-in-class platform.

Another centrepiece was the world premiere of the HyPET6e platform, which builds on these advances to deliver productivity, material protection and consistent quality, even with high levels of recycled content. Complementing it, the newly introduced HyPET NX6 offers a cost-effective, mid-volume PET system for efficient preform production.

During the press tour, Husky officials emphasised the importance of meeting Europe’s Packaging and Packaging Waste Regulation (PPWR) requirements by embedding intelligence into systems. These include real-time preform inspection, colour correction, smart start functions, and QR-enabled maintenance tools. The goal, they said, is to help producers overcome common rPET processing challenges such as hazing, discolouration, and variability.

Husky also launched HyCAP SecuRE+, a closure technology that enables bottles and caps to be made entirely of PET, creating a fully circular mono-material package. The system introduces a novel tamper-evident design, improved capping performance, and compatibility with tethered closures and standard CETIE neck finishes.

“The combination of our next-generation HyPET6e 200-cavity system and new HyCAP SecuRE+ closure technology represents game-changing advances for the beverage industry,” said Robert Domodossola, Husky’s president of systems and tooling. “Producers can achieve unparalleled scale and efficiency while processing higher levels of rPET with confidence and consistency, while also moving towards true mono-material packaging.”

The company also officially launched Advantage+Enterprise, an expanded monitoring solution that builds on the Advantage+Elite system already deployed in more than 1,500 contracts worldwide. The enterprise-level platform offers factory and multi-factory visibility, predictive maintenance, and data-driven insights to optimise rPET integration, labor allocation and waste reduction.

“Our customers need more than system-level alerts — they need enterprise-wide insights across global networks,” said Tony Black, president of service at Husky. “Advantage+Enterprise delivers that visibility, driving efficiency, quality, and resilience while helping producers bridge labour gaps and optimise equipment effectiveness.”

Closing the press tour, Selleck stressed Husky’s long-term vision of PET as the most circular packaging material. “We want our customers to deliver the world’s highest output at 100% rPET — sustainability without compromise,” he said.