We walked over to the Miyakoshi stand with Akshay Kaushal and were introduced to the owner and president of the company, Toru Miyakoshi. While other OEM’s machines are also built by Miyakoshi, presses, the company itself builds and sells a considerable range of presses using a variety of technologies and aimed at specific applications. In many ways, it seems that the company’s production schedule is filled with bespoke orders for offset, inkjet, flexo, and hybrid technology presses for labels and flexible packaging.

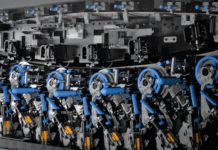

On its stand, Miyakoshi introduced two new press models, the LPS 13A, which is an offset and flexo combination intermittent press with AI integration; and the MJP14LXA, a water-based high-speed inkjet press. The LPS 13A was shown in a 330 mm width with five flexo units, one flexo unit, and a die-cutting unit with Miyakoshi’s motorized gap master function, running at 200 impressions a minute and approximately 66 meters a minute. In what is claimed to be an industry first, Miyakoshi introduced two revolutionary press automation features using artificial intelligence at Labelexpo – the Yaless AI and Yaless Eye.

As Kaushal explained to us, the Yaless AI constantly monitors key factors of the machines and the pressroom conditions, such as the ambient temperature, dampening water conditions, ink temperature, ink density, and other parameters to use AI expert systems or algorithms to predict the output and auto-adjust the printing conditions, and prevent errors and quality deviations beyond present tolerances. (There is a semi-automatic option for this AI system in which the operator can manually respond to various prompts with Yes or No.)

As Kaushal explained to us, the Yaless AI constantly monitors key factors of the machines and the pressroom conditions, such as the ambient temperature, dampening water conditions, ink temperature, ink density, and other parameters to use AI expert systems or algorithms to predict the output and auto-adjust the printing conditions, and prevent errors and quality deviations beyond present tolerances. (There is a semi-automatic option for this AI system in which the operator can manually respond to various prompts with Yes or No.)

The second AI feature, the Yaless Eye, enables operators to control the press using voice commands, in any spoken language, facilitating an environment for intuitive, hands-free operation and faster troubleshooting. This option is currently available for Europe and Japan, but what is interesting is that it could be retrofitted later, on a number of Miyakoshi machines. The demo L13A press was purchased by a European customer.

Apart from the AI automated hybrid flexo and offset label press, Miyakoshi introduced the new water-based inkjet MJP14LXA, meant primarily or currently for paper labels. Running at 80 meters a minute, it uses a hot air drum for curing while the film application is still under development. This press is expected to enter the label market next year.