Valence Electrons, based in Bengaluru, India, has offered an innovation to a converter in western India with its Lamiflow heat recovery system. A part of the ATE Group, which provides solutions in textile engineering, cooling solutions and print and packaging solutions, Valence claims its Lamiflow heat recovery system is an attractive investment because it reduces heating costs by recovering heat from hot exhaust air of the drying process.

Conventional drying process

As part of the conventional drying process, a converter coats the films with a uniform thickness of a special solvent-based material. The coated film is then passed through a drying chamber where thermic fluid is used for heating. Waste hot air that is used for drying is exhausted from a dryer at 155oC.

New drying process

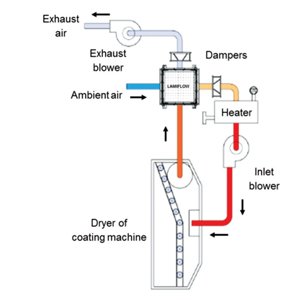

As part of the new drying process, Valence suggested the converter in western India to evaluate the feasibility of energy-recovery devices to reduce heating costs. This converter has state-of-the-art speciality coating line where it processes polyester(PET) films, 10 – 350 µm thick. The Valence team observed that 80% of the energy of hot air was being wasted. To extract a good part of the heat, Valence proposed the Lamiflow heat recovery system which is a cross flow, air to air heat exchanger. It comprises multiple, thin, slightly separated plates that provide a large surface area for effective heat transfer with low pressure drop.

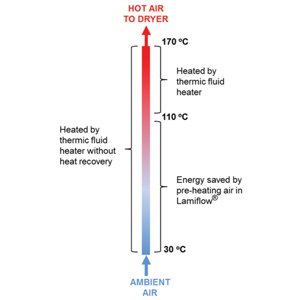

The Lamiflow heat recovery system is installed in a way that the two air streams – ambient air and hot air exiting from the dryer – cross each other with out mixing. The heat extracted from the exhaust air is effectively used to pre-heat fresh air before it enters the heater. Thermal energy costs are thus reduced by decreasing load on the heater.

Keeping in mind 16 hours of operation of the coating machine each day, for 300 working days in a year, and assuming that savings happen only 60% of the time, this solution pays for itself in about seven months. The customer can save cost and explore other areas for waste heat recovery through this system