I wrote about the Tokyo Pack show, which I want to follow up with this story about a second show, Label Forum, which took place at the same time. It’s convenient to think of the two shows together since they both took place at the same exhibition center, Tokyo Big Sight.

However, they were organized by different companies and were in different wings, with a short trek between the two, and each required their own tickets. For me, Label Forum, despite being a much smaller show, was more focused and, therefore, more interesting from a print point of view though the stands were relatively small so that most companies showed samples rather than presses.

That said, Epson showed off its new label press, which I’ve already covered when it was shown as a prototype at drupa. Since then, it’s gained a name and will be sold as the SurePress L-5034, though it won’t be available until the summer of 2025.

This press builds on the approach that Epson developed for its L-4000 series, which uses a water-based resin ink. These presses produce very good quality labels but their weakness has always been the slow speed. This new model can produce up to 13.5 mpm, which is not by any means a fast speed but is considerably better than the 8.2 mpm of the current models. Tomoaki Kimura, general manager for commercial and industrial planning at Epson, told me, “We have internal discussions about the speed but first we focused on getting over 10mpm but with the same quality.

The issue with the speed is that, as with the existing L-4000 series machines, this is not a single-pass machine. Instead, the substrate roll stops while the press prints one frame, then advances and stops to print the next frame. However, Epson has increased the size of that print frame, which is now almost 1.3 m long, and the frame itself is printed in a single pass. It still uses a water-based resin ink though the formulation is different because Epson has separated the pre-coat or optimizer from the ink.

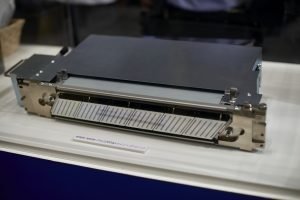

Naturally, Epson has developed the printhead itself for this press. The head looks a lot like Epson’s D3000 head but predates that head. As with the D3000, it’s a 1200 dpi head with a parallelogram shape that allows multiple heads to be slotted together on a single printbar. Kimura points out that the D3000 only offers a single channel at 1200 dpi, noting, “This head can support two colors so it can be more compact.”

Thus there are five printbars. One is for the optimizer or primer, with Epson using the two channels in the heads to run two different optimizers— one is for printing to paper-based substrates and the other for printing to film labels. The other four printbars are set up with two colors each, allowing the press to lay down eight colors with very little space between them.

That said, the L-5034 does not include white, which does seem like a major drawback for a commercial label press though Kimura says that Epson would like to add this in the future.

Another potential issue is that, unlike the D3000, this printhead does not include recirculation. Again, Kimura says that Epson would like to add this in the future. Presumably, there’s also an issue as to how much space Epson can find within the press because the obvious solution would be to add a row of D3000 heads with recirculation for the white ink.

Epson is using a Nozzle Verification Technology to monitor the nozzles in real-time. This uses feedback from the drive signal, as the pressure and, therefore, the residual vibration differs between blocked and clear nozzles. As it happens, Meteor Inkjet has patented a similar system.

Epson has taken an interesting approach to servicing the printbar that it still seems to be considering. Kimura explains, “The customer can swap out the entire print bar and ship it back to be serviced.” Epson seems to be debating whether or not this would be more efficient than sending a service engineer.

Canon LS2000

Not to be outdone, Canon showed samples for its upcoming LS2000 LabelStream inkjet label press, though wouldn’t let me take any away. However, the samples did seem very good, with very sharp definitions on small point-size text. As with the Epson press, Canon’s new label machine also uses water-based inks, though Canon didn’t bring the press itself, which is quite a bit bigger than the SurePress.

Naturally, as the commercial release for the LS2000 is getting closer, Canon is sharing slightly more information. Thus the thermal printheads can achieve 2400 x 1200 dpi resolution and are said to have a newly developed recirculation method. It is said to feature precise flow paths allowing the ink to circulate to the tip of each nozzle, and is backed up by automatic maintenance routines.

The ink is described as being a high-concentration resin ink and will include an opaque white as well as CMYK. This ink is said to produce a very thin ink film that will allow the substrate to retain its texture. It will print to coated paper, synthetic paper and film label stocks. Canon is clearly targeting food packaging applications as well as labeling, noting that the ink cures at a very low temperature so that it is suitable for heat-sensitive films and meets all US and EU safety standards for materials that are not in direct contact with food and cosmetic packaging.

It won’t be available until 2025 though Canon has now indicated that the pricing for the Japanese market will be around ¥50 million, or roughly £260,000 or $330,000 at the current exchange rate.

Whilst at Tokyo Pack, I came across a Durst large format hybrid printer on a distributor’s stand. But over at Label Forum Durst’s own European staff were on hand alongside an entry-level Tau 340 E. Thomas Macina, Durst’s sales director for labels and packaging, says, “I think that more large format customers are trying to get into packaging to differentiate themselves. So it’s quite common that a large format customer will opt for digital labels.”

He accepts that the Durst label press is expensive but says: “I think the most important thing is the print quality but also the reliability and the way that it works.” He says there are quite a lot of Japanese competitors for digital label presses but that they are mostly aiming for the cheaper end of the market, adding: “But for most customers, it’s good to start with the entry-level machines. Once they have filled the machine with short runs then I think this machine is ideal.” He says that it’s harder to sell the Tau to customers that don’t have a short-run business but notes, “If you can fill this machine with two hours a day then you will have a business.”

He says that customers should consider the total cost of ownership, including the servicing and upgrade options, noting, “You can upgrade this Tau 340 E to 80mpm, mainly with software and some components.” He added, “Also, most importantly, you can start with CMYK only but if you require orange and violet then you can upgrade the colors later. And for customers who do not know what they are going to print then that’s the right approach.”

Screen laser printer

There were also a number of tabletop label devices at the show. Screen played host to a small laser printer, the Valloy BizPress 13R, which is made in China but sold through a South Korean supplier, and which Screen will also be selling in Japan. This helps to round out Screen’s label portfolio, which now includes this compact press, Screen’s own Truepress Label 350UV inkjet label presses and Nilpeter’s Flexo presses. The main benefit of this machine is its extremely small size. It’s a four-color machine – CMYK – with an optional white and is based on a Xerox Phaser 7800 engine. It takes media rolls from 210 to 330mm wide and will print to both paper and film stocks. It runs at 7.26 mpm. It can also be paired with a finishing device from Rose, which offers slitting and laminating and can run at 9 mpm but averages 4 mpm.

Continuing the desktop theme, Anytron showed off its Any 002 machine, which is based around an Oki color laser engine with winders eon ither side and can be used for both short-run labeling and flexible packaging. It takes rolls up to 215mm wide and has 600 x 1200 dpi resolution with a speed of 9mpm. It has a sensor that can pick up gaps and registration marks, which allows for accurate front-to-back registration. It can also be used for foiling, by printing the black toner first where the foil is to go and then running this through a separate foiling machine. After this, the label roll can be put through the Any 002 for color printing.

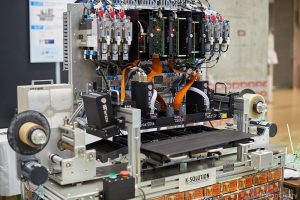

K-solution brought along its inkjet evaluation device, which has been designed to allow systems developers to test different printheads and inks. The basic machine has been around since 2013 but K-Solution has now added a roll-to-roll continuous feed capability. Yasushi Katsuta, representative director for K-Solution told me, “We have had more interest in this than we expected.”

Katsuta says that it will work with any printhead on the market. For LabelForum it was configured with a selection of heads, including Xaar Nitrox, Epson PrecisionCore and Ricoh. The printhead driver boards come from Meteor Inkjet.

The machine can be set up with six colors, including CMYK, white and varnish. The fluid management system comes from MegnaJet, which is a subsidiary of Xaar. It will work with most types of ink, including aqueous, UV or solvent, and can handle both recirculating and non-recirculating heads. The machine at Label Forum was set up with IST UV curing, since K Solution is also the IST distributor, but Katsuta says that customers can choose the curing system or can use infrared or a heater.

GEW showed off its latest LED UV curing units, the water-cooled Leo LED2 and the air-cooled Aero LED2. These systems are widely used on label and sheeted offset presses with UV inks. Their main advantage is the ease of swapping out the internal lamp modules, such as from UV to LED, since they all use the same casing, control units and power supply. Marcus Greenbrook, director of international sales for GEW, says that customers need this flexibility because not all applications are fully covered by the current range of LED inks.

The advantage of the v2 units is that they allow for more power. Greenbrook explains, “The Aero LED2 now runs at the same power as the original Leo LED but without needing the water and chiller. We think that in narrow web flexo, water-cooled LED systems are becoming obsolete.”

He says that there has been a slight decline in curing performance over the last year because the inks have had to be reformulated to comply with new safety regulations, noting: “So adding this extra boost in power will help the customers achieve the speed that they want to be running at.”

I also came across Hybrid Software, which used the show to market its software, including the Packz and Stepz PDF editors and the Cloudflow production workflow alongside the Global Graphics’ SmartDFE front end.

Hybrid Software

Hybrid Software has recently introduced a new offering called Brandz. Mike Rottenborn, CEO of the Hybrid Software Group, explained that whereas the existing software has been targeted at designers and print production users, Brandz is aimed more at brand owners who need to manage their artwork portfolio. Brandz is a business unit rather than a product and offers mainly hosted artwork management. Its first actual product is Artflow, a SaaS solution that includes 2D and 3D visualization and approval tools as well as a way of managing briefings and project scheduling.

Overall, Label Forum was a relatively small show but benefitted from being close to the larger Tokyo Pack event. It had a more international feel though that may just be because it was smaller and easier to navigate. The Label Forum event was organised by the specialist publisher Label Shimbun.