The potential for lenticular printing has ‘no real limits’ thanks to new technology able to print the lens directly onto any type of transparent substrate, to deliver ‘impressive’ three-dimensional (3D) optical effects combined with photographic-quality printing more quickly and cheaply than ever before, say the developers of a system initially launched for point-of-sale (POS) applications and on track to enter the labels market before the end of 2015 under the Popims Printed Optics brand.

Printed Optics has recently taken on its first certified label printer. Next Label, a specialist in 3D labels using printed optics based in France, was appointed by French software and patents developer Popims Lens Printer, the lead company in the project.

Pierre Guigan, manager of Popims Lens Printer, told Packaging South Asia that Next Label “will also be the laboratory to develop new effects.” The company which previously was known as ETTA is headed by its new president Didier Guenu.

The first certified printer manufacturer in the POS market, SwissQprint, of Switzerland, introduced the technology, which it has renamed Droptix, at the digital print show Fespa in Cologne in 2015. Unlike standard lenticular printing calling for expensive lenses, the lens is printed by applying varnish to a transparent substrate. This makes the optical effect quicker and cheaper to produce and allows the user to print 2D high-definition (HD) images in combination with ‘astonishing’ 3D effects says SwissQprint.

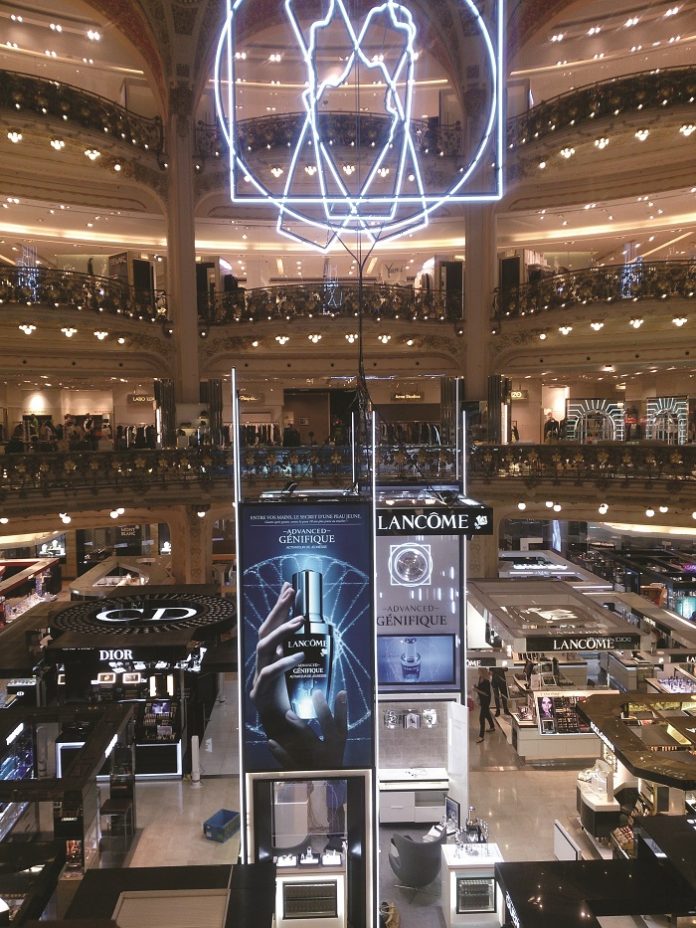

In February 2015 the technology had its first commercial unveiling in France in its largest-ever POS application by the luxury cosmetics brand Lancôme. The 1.75 x 3.65 metres billboard was installed as part of a two-week product promotion inside Galeries Lafayettes Haussman, a landmark store in the centre of Paris. “Lancôme was the first commercial user of this technology in so big a format,” said Guigan, adding that Unilever and L’Oréal were previous sponsors of the technology. To explain the innovative elements of Printed Optics that improve on existing lenticular printing, Guigan said, “We print the lens directly on any type of transparent substrates thanks to patents protection and specific software and chemistry developments, and the technology gives lenticular more depth and numerous new products and applications. It is now possible to apply lenticular directly on a shop window or make a roll-up . Almost any size is possible.”

Meanwhile the technology is being optimized for labels and trial results are ‘very good’ said Guigan. “We have very innovative solutions to come in the labelling industry. Lenses are reduced to 60 microns in diameter and printed in UV flexography. With 3D effects such as moiré mixed with photographic printing quality, results should be impressive.” He said Printed Optics is targeting personal care, skin care, beverages and other product categories that use adhesive partial labels, and marketing campaigns will launch new products with specific brands.

In large-format applications Digital Packaging, of Sèvres in France, is the most advanced user. Printers around the world can use the technology under license, said Guigan: “Each license allows a specific printer to be trained to offer all achievable effects. The printer and license relate to the needs of a particular end customer. Eventually all licensed printers will become experts in all types of effect on any substrate. “There is no real limit to what

can be achieved using the technology. The first ‘classic’ license was issued in June 2014 and now some 110 printers around the world are geared up to produce on a limited scale.”

Guigan explained that SwissQprint is certified for large format POS products and supplies resellers who give printers the training and support they require. Final customers can achieve the effect they want from printers using the flatbed presses for POS production on thicker substrates, and at present the skill and equipment is mostly located in Europe, the United States of America and China, said Guigan.

A prototype 3D label application back in 2013 took the form of a 3D cutout of a bottle, displayed by Printed Optics supplier Sun Chemical at the German Interpack packaging show. By the end of 2015 label printers will have access to licenses and specific varnishes developed and supported by Sun Chemical and 3D certification by Graphi Label and Popims Lens Printer. The technology will be available to any high-quality label printer equipped with a flexography press of minimum 8 colors. The license for patents is based on volume with the cost of production estimated to be around 3 Euros (`240) per 1,000 labels.