PPi Technologies Group, a leader in flexible packaging, launches a cooperation agreement with PopPack, offering what are being called ‘Air-Powered Package’ design technologies to easily open flexible packages. The EasyPop innovation is based on a simple concept – using an air bubble which functions as a lever to easily open packages including pouches when the bubble is popped.

PPi Technologies will be customizing PopPack’s EasyPop feature to make commercial prototypes at their packaging incubator facilities in the United States. Multinational brand owners have expressed interest in applying the technology developed by PopPack.

Being a packaging converting and FFS machine manufacturer, PPi Technologies has the expertise, know-how, and capacity to produce customized packaging solutions for its customers and to complete the required R&D to make packaging prototypes. As a packaging converting machine manufacturer, it can implement production development and machinery modifications required for commercial production and scalability, incorporating the EasyPop feature in flexible packs.

“The Air-Powered Package is a next-generation package feature, designed with a consumer-first approach. It has impressive functionality with built-in consumer convenience for producing easy-to-open packages. PopPack’s technologies will broaden packaging solutions offered by PPi Technologies Group with alternatives for consumer convenient packaging with greater production efficiencies. We look forward to working with our new and existing customers to implement the novel Easy Pop packaging features for commercial production,” says R. Charles Murray, CEO of PPi Technologies Group.

PopPack – easy to fill & seal – easy to open with one hand

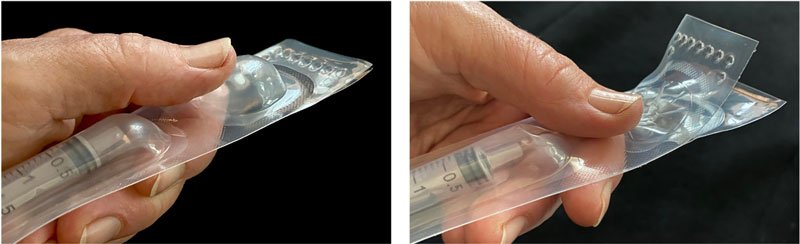

PopPack’s solution is suitable for consumer products packaged on vertical or horizontal form, fill, and seal machines, and thermoformers. The packages are easy to open and can be combined with reclosing and self-closing features eliminating the need for scissors, knives, teeth or tear strips or caps to open flexible packages. PopPack’s EasyPop design technologies apply to solids, liquids, and powders for food and non-food products.

PopPack’s EasyPop design technologies produce a distinct and appealing ‘popping’ sound which instantly engages the consumer and provides assurance of freshness, tamper-evidence, and product safety. The package design offers improvements for flexible packages to reduce pathogens and contamination of the product. Packages can be opened with only one hand, making this design feature ideal for on-the-go consumers. EasyPop is appropriate for snacks, foods, condiments and beverages, as well as for packaging personal care and healthcare products, cosmetics, lotions, consumer goods and convenience products. The EasyPop design-tech meets sustainability goals.

PopPack received the Packaging Innovation Award for Creative Technology at Japan Pack and the Packbridge Easy Open Award in Sweden for its novel ‘bubble in the seal’ easy-to-open packaging innovations. PopPack holds over 150 patents issued and pending, with accompanying trademarks related to its innovation of the Air-Powered Package. Patents and trademarks are issued in the Americas, Asia, Middle East, Europe, and Oceana.

PopPack is an appropriate innovation – our view

For the past four years, Bill Perell the inventor of PopPack has been showing it to us and interested converters in India. We remain convinced that the technology can firstly provide easy to open flexible pouches to Indian consumers, and secondly, help in the collection and sorting of flexible waste at source since there is no tear-off piece of the package to be recovered along with the main pouch. The innovation is implementable by flexible packaging converters in India and only requires a relatively small modification of the FFS machine. Check out the PopPack video here.

Both Bill Perell and Cheryl Harrison have supported and taken part in the Packaging Design Innovation and Technology Conference held in 2017 in Mumbai and the Packaging Design Innovation and Technology Conference held in 2019 in New Delhi. Harrison was the keynote speaker at the PDIT 2 Conference. PPi Technologies is taking part in the PackExpo 2020 virtual exhibition and converters can learn more about ‘Air-Powered’ packaging by checking their virtual stand there.