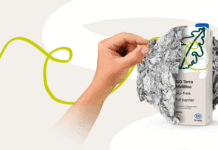

Tetra Pak announces an ambitious investment program dedicated to its factory in Châteaubriant, specializing in the production of caps. Spanning across three years (late 2021-2023), this €100 million project will support the plant’s transition to the production of tethered caps by 2024. Tethered caps help to minimize litter, as the cap will stay attached to the package. Tethered cap on Tetra Pak carton In addition to the company’s commitment to invest approximately €100 million per year over the next 5-10 years to develop more sustainable packaging solutions – is key to ensuring that Tetra Pak’s customers in Europe will be ready to comply with the Single Use Plastics (SUP) Directive, an integral part of the wider approach announced in the Plastics Strategy and an important element of the EU Circular Economy Action Plan. Charles Brand discussing Tetra Pak investment project Charles Brand, President of Tetra Pak Europe & Central Asia Charles Brand, President of Tetra Pak Europe & Central Asia, comments: “We are particularly proud of this investment project, which demonstrates how we consistently strive…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*