Parksons Packaging, one of India’s largest monocarton printers and converters, ordered two of the latest generation Speedmaster CX 102 presses at drupa 2016. The company has developed a strong partnership with Heidelberg since its establishment in 1996, and has installed numerous Heidelberg presses over the years. “Two years ago we were looking around for a press capable of producing the increasingly short-runs in packaging printing quickly and economically, and decided on the Speedmaster CX 102 after a long search,” explains Ramesh Kejriwal, founder and chairman of Parksons Packaging. “It exceeded our expectations, and we ended up installing two more CX 102 presses.”

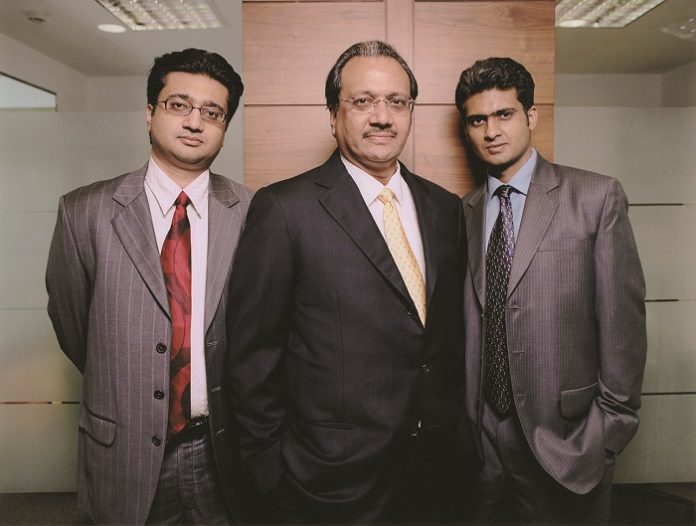

Ramesh Kejriwal and his two sons were impressed by the latest automation features of the Speedmaster CX 102 generation at drupa 2016. Their further investment in a pair of CX 102 presses long and highly automated configurations for carton packaging represents the biggest order for Heidelberg India at any drupa trade fair. The first of the two presses will be installed at Parksons Packaging’s new plant coming up in Sricity in Andhra Pradesh just 55 kilometres north of Chennai in South India. Running trails of the press at the new plant are expected to take place in December 2016.

Complete package for a safe investment

Heidelberg’s strategy of delivering a complete and optimally coordinated package comprising machines, services, and consumables was a decisive factor. “The new machines will mean shorter makeready times, faster job changes, and greater automation. This high productivity is all the more important for us given the steady increase in labour costs in India,” says Ramesh Kejriwal. Like the Speedmaster CX 102 presses already in use in the company, the new machines are also equipped with Prinect Inpress Control for automatic verification and control of color and register on the fly. The new Speedmaster CX 102 generation is also easy to use thanks to the Prinect Press Center XL 2 and the integrated Intellistart 2 software. It guides the operator through the workflows and calculates the fastest way of changing from one job to another.

“These two new machines will mean fast resumption of production after the many ink changes we are faced with in packaging printing, and the high level of automation will ensure high quality with less waste,” explains Ramesh Kejriwal. “Our business has grown by 25% CAGR (compound annual growth rate) in the last ten years, and we want to invest carefully to continue this growth in the future. We are impressed by the reliability and stability of Heidelberg’s machines.”

Parksons Packaging has its headquarters in Mumbai with four other production locations in India including Daman, Chakan, Haridwar and now Sricity. The company employs over 1,200 people in total and produces high-quality folding cartons for customers in India as well as international manufacturers of branded goods. It processes over 70,000 metric tons of paperboard each year.

Packaging South Asia is a cooperating media partner for drupa 2016 which was held from 31 May to 10 June at Dusseldorf, Germany