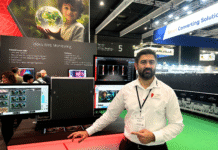

Naph Graphics showcased the Slitline 35, which was launched during PackPlus 2016. Mohit Bansal, assistant director marketing, Naph Graphics said, “Till date we have sold four of these machines. So it has been a good year for us as far as this machine is concerned.” Talking about the response at the show, he said that Naph Graphics received many inquiries right from the opening day and expected the footfall to pick up with more inquiries.

The Slitline 35 is designed for flexible packaging films, foil, paper, film laminates, paper and board. It has a maximum web width of 1300 mm and can handle plain, coated and metallized films as well as film, foil or paper laminates from 12 to 200 microns, and paper and board from 40 to 200 gsm. The Slitline 35 features a laser light for better positioning of cores during changeovers; a camera-based web guiding control system; a vacuum suction trim blower with trim rewinder option; camera-based viewing of the unwind section; an optional hydraulic reel lifting system; and a rewind roll unloading stand. Talking about his company’s strategy, Bansal said that the plan now is to build the right team to focus harder and improve their presence in the market. The policy that Naph Graphics strictly follows is of knowledge sharing with the target group before trying to sell a product. Recruiting the right talent and then training them to get familiar with the target market before asking them to sell is how Naph Graphics proposes to consolidate and move forward. Secondly, the company also plans to divert its focus on slitters apart from its web offset presses. According to Bansal, the company plans to expand its product portfolio in the near future and will make an announcement to that effect very soon.

The Slitline 35 is designed for flexible packaging films, foil, paper, film laminates, paper and board. It has a maximum web width of 1300 mm and can handle plain, coated and metallized films as well as film, foil or paper laminates from 12 to 200 microns, and paper and board from 40 to 200 gsm. The Slitline 35 features a laser light for better positioning of cores during changeovers; a camera-based web guiding control system; a vacuum suction trim blower with trim rewinder option; camera-based viewing of the unwind section; an optional hydraulic reel lifting system; and a rewind roll unloading stand. Talking about his company’s strategy, Bansal said that the plan now is to build the right team to focus harder and improve their presence in the market. The policy that Naph Graphics strictly follows is of knowledge sharing with the target group before trying to sell a product. Recruiting the right talent and then training them to get familiar with the target market before asking them to sell is how Naph Graphics proposes to consolidate and move forward. Secondly, the company also plans to divert its focus on slitters apart from its web offset presses. According to Bansal, the company plans to expand its product portfolio in the near future and will make an announcement to that effect very soon.

When asked about the main challenges that Naph Graphics currently faces, Bansal was quick to point out that organizing the right work force appeared to be a big challenge. “It is very difficult to find the right talent in adequate numbers and retaining them is another challenge. Today, bagging orders is easier than delivering the orders on time and that is directly connected to availability of talented workforce. In today’s high attrition labor market, it is vital to find the right talent first, train them up and then retain them in a specialized engineering company that builds industrial machinery,” he concluded.