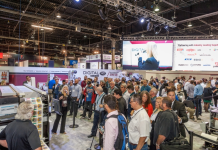

Gujarat-based Mamata Machinery had two separate stands at the recently concluded Pack Expo International, which was held in Chicago from 6–9 November 2016. While one stand was dedicated to the converting side of the business and displayed a pouch-making machine called Vega 410, the second one was dedicated to the packaging side of the business and displayed a horizontal form fill seal (HFFS) machine and a pick fill seal (PFS) machine. “We demarcated the two divisions and had separate stands because we wanted

to address the right audience,” says Apurva Kane, senior vice president, Mamata Machinery.

The pouch maker Vega 410 was demonstrated in joint promotion with HP and Mamata’s US customer, ePac, which is a short-run packaging solutions provider based in Madison, Wisconsin and has multiple HP Indigo 20000 presses. “We were running digitally printed films on our machine. The Vega 401 is a narrow web machine with fast changeover time,” Kane says.

At the second stand, the HFFS machine being demonstrated was the large format machine which can handle maximum pouch size of 260 mm X 400 mm. The machine is meant for packaging mainly snack food. The PFS machine on display has been designed in the US but fully made in India. “We received very good feedback for our India-made PFS machine. The quality and aesthetics of Indiamade machines is as good as that made in the US,” says Kane.

Currently, Mamata has two units in the US—Montgomery in Illinois and Bradenton in Florida. The Montgomery unit started operating in 2004 and focuses on converting solutions which are made in India. The six people employed at this unit look after sales and after-sales activities. The Florida unit, comprising of 17 employees, focuses on manufacturing of packaging machines like the HFFS machines.

The US operations now contribute 25% to Mamata’s overall business but Kane believes the share is poised to increase rapidly. “In last few years, our US sales have grown rapidly and soon we expect the business to be as big as our Indian business,” he adds. To focus on value addition in the US market, the company plans to shift its core manufacturing operation from the US to India. “It does not make sense to get bogged down by core manufacturing operations here in the US. Rather, we would concentrate on value addition activities in the US. To this effect, we are looking to expand our Indian manufacturing operations. By this we will also be able to contribute to the Make in India initiative as well.”