In the wake of the mandated pan-India lockdown, Saicom Code, one of the leading label converters in the country, has switched to digital label production to keep the supply of essential goods and services in seamless motion. To achieve this, the company is leveraging Accurio Label 230 Digital Label Printing solution from Konica Minolta, major digital solution provider in the country from print business perspective.

With label production facilities in North, East, and West India, Saicom Code produces pressure-sensitive labels for various industries such as Pharmaceutical, Cosmetics, Oil, Food, Liquor, Perfume among others. Since the onset of the Covid-19 pandemic, the Government of India implemented a nationwide lockdown to curb the spread of infectious disease. Against this backdrop, the demand for labels of essential goods including preventive medicines, sanitizers, liquid soaps, health supplements, cough syrups, among others registered a massive surge.

Consequently, manufacturing companies required labels urgently in small batches and at regular intervals to cope with the sudden spike in demand. To bridge this extraordinary need-gap and in view of the impaired supply chains amid the lockdown, the company decided to embrace the power of innovation. In sync with this, Saicom Code, under its production business vertical Sai Digistik, has met all the urgent label requirements on Konica Minolta Accurio Label 230 label printing machine at its Sonipat Plant.

Harish Gupta, director, Saicom Code, said, “To overcome the mobility restrictions imposed by the lockdown, we decided to print labels digitally to enable immediate delivery of labels to the manufacturers of essential goods and services such as soap, sanitizer, medicines, among others. Besides the travel restrictions, the other main challenge we had to deal with was the low workforce availability. This is exactly where Konica Minolta came to the rescue by resolving the lockdown-induced operational bottle necks. After receiving the required permissions from the government authority managing essential goods services, we started digital label production on Konica Minolta digital label production system. We would like to express our heartfelt gratitude to the Konica Minolta engineering team that supported the production remotely by offering the technical expertise required to improve productivity during these difficult times.”

Manish Gupta, general manager, PP and IP marketing, Konica Minolta Business Solutions India, commented, “We are pleased to have Saicom Code as our patron. Driven by the motive of supporting humanity, Saicom is leveraging its expertise to enable the industry to meet the present-day requirements. Doing so, Saicom has created an unbreakable bond with its end-customers by serving as unflinching support during the stressful manufacturing environment.”

Speaking on the advantages of digital label production, Manish Gupta added, “Digital label production process has few advantages, like short turnaround time, variable data printing, quick delivery time, ease of operation with one labor, fast job changeover, less media wastage, and cleaner environment.”

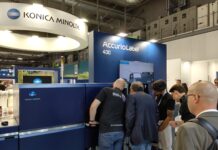

With a maximum print speed of 23.4m/min and a warm-up time of less than 30 seconds, the Accurio Label 230 is designed to deliver superlative value addition through best-in-class print quality, productivity, and operational flexibility. It facilitates higher print output and faster turnaround times between print jobs and is capable of handling a wide range of print media – including non-tack/tack paper, tack coated paper G/M, synthetic paper, PP, and PET – and thicknesses of up to 256 gsm.

Besides its operational speed and flexibility, the Accurio Label 230 differentiates itself from competing products with its unique overprinting solution that automatically adjusts the overprint position for accurate registration; this reduces print wastage and lowers operational costs for print businesses. The machine also comes equipped with advanced variable data printing (VDP) capabilities, making it perfect for short-run print jobs that require a high degree of personalisation. Its compact, ergonomic design also makes it possible for the Accurio Label 230 to be installed in large print setups alongside other machines, as well as in smaller print shops.