In Europe and North America, some 100 kilograms of food is thrown away per person each year although it is still fit for consumption. Demands for a change of attitude are therefore coming from the highest authorities. At his general audience during World Environment Day last June, Pope Francis called for an end to consumerism and the wastage of food.

Innovative packaging is an important element in the fight against food loss and wastage. More effective barrier layers, germicidal films and freshness indicators are intended to help products to keep for longer and halt consumers’ throwaway mentality. However, despite all these improvements, companies have to keep a constant eye on process efficiency and on costs. In the developing countries, one child in six is undernourished, which amounts to an absolute figure of 100 million. The United Nations estimates that undernourishment causes the deaths of 2.6 million children under five years old each year. This means that hunger is still one of the biggest scourges of humanity.

Yet no one should have to go hungry. Every year some 1.3 billion tonnes of food worldwide ends up in the bin — a conclusion of the current report ‘Food Wastage Footprint: Impacts on Natural Resources’ of the Food and Agriculture Organisation of the United Nations (FAO). If food losses were reduced by using food more prudently, famines could be curbed.

The report says 54% of wasted food is lost during production, post-harvest treatment and storage. Particularly badly affected are the poorer countries of Africa and Asia where shortcomings during harvesting and logistics destroy 6 to 11 kilograms of food per capita each year. Exposed to heat, fruit and milk spoil, and meat is rendered inedible by contamination with dangerous germs. On the other hand, wastage during processing, transport and consumption is more a problem of the industrialized nations.

Central theme of interpack 2014

developing countries, a great deal of food spoils

due to shipment in its unpackaged state after

harvesting. Simple anti-spoilage packages like

these cans could prevent this. (Photo: Messe

Düsseldorf/Tillmann)

Industry has already got the message. According to a current study by the Royal Melbourne Institute of Technology in Australia, suitable packages are capable of reducing food loss considerably. Developers are therefore working hard on new concepts for packaging machines, the related process technology and ‘smart’ packages. A total of 100 companies from the entire food value chain, from production, retailing and packaging through to logistics, are now participating in the Save Food Initiative, a joint project of the FAO, the United Nations Environment Programme (UNEP) and Messe Düsseldorf GmbH. Its goal is to foster dialogue between industry, research, the political sphere and civil society on the subject of food loss.

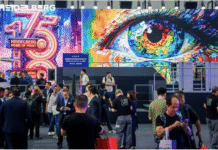

Reducing spoilage will also be the central theme at the Innovation parc Packaging at interpack 2014 in Düsseldorf. From 7 to 14 May 2014, exhibitors at this special show will be presenting their ideas on how food can be protected better. Furthermore, during the Save Food Conference at Messe Düsseldorf’s Congress Center South on 7 and 8May, experts from politics, industry and society will be exchanging views on food loss and wastage.

The sector has a lot of work ahead of it. Farmers in Africa first have to be convinced that it is better to package their produce at source than to send it off unprotected. It is not high-tech that is called for here, but education locally. Representatives of companies like Bosch, for example, therefore toured emerging and developing countries with mobile packaging machines some years back in orderto demonstrate to farmers the advantages of packaged foods.

The throwaway mentality of the Western world, on the other hand, is even more difficult to combat. According to a survey by Berndt+Partner management consultants, 20to25% of food in Europe is binned even though it is still fit for consumption. One contributory factor is the ‘best before date’ that has to be printed on all food packages. Once it is reached, food is often thrown away. However, ‘best before’ does not mean that food is no longer edible after this date, but merely that its colour and consistency may change. The currently widespread large packs exacerbate the problem. The best before date is often reached before the package contents have been consumed.

Smaller, customized packages should help to solve the problem. “In our view, portioned packages for one-person households, for example, can help to stem food wastage,” says Christian Traumann, managing director of Bavaria packaging specialist Multivac Sepp Haggenmüller.

Creative package solutions

Reporting continuously on a product’s state of freshness with time and temperature indicators are another approach in the battle against spoilage and waste. The useful thing about them is that they render visible any breaks in the cooling chain, for instance. BASF and the Swiss Fresh point company are already producing labels containing a special pigment which are printed straight onto the package. The colour changes when the contents spoil.

Reporting continuously on a product’s state of freshness with time and temperature indicators are another approach in the battle against spoilage and waste. The useful thing about them is that they render visible any breaks in the cooling chain, for instance. BASF and the Swiss Fresh point company are already producing labels containing a special pigment which are printed straight onto the package. The colour changes when the contents spoil.

Research is also being conducted on active packages that interact with their contents. PET bottles are treated with oxygen absorbers like iron so that oxygen sensitive beverages such as beer and fruitjuice keep for longer. Then there are films enriched with preservatives like sorbic acid that combat germ proliferation on foods. Critics claim thatthe additional chemicals on active packages impair the products’ natural quality. In their search for a remedy, scientists of the Fraunh ofer Institute for Process Engineering and Packaging (IVV)in Freising, Bavaria, are developing antimicrobial materials based on plant extracts ,for example,from rosemary. “This way, food manufacturers can go further towards meeting the consumer’s wish for natural, health promoting products,” says IVV materials developer Sven Sängerlaub.

Thedownsideofmany food-savingpackages,however,is thattheyare relatively expensive to produce. If, for example, a ‘stronger’ package calls for more material, it uses up more resources. The sector is therefore trying to offset the expenditure on ‘smarter’ packages by economizing elsewhere along the food value chain. The manufacturers of packaging machines therefore endeavour to boost the efficiency of their lines by increasing the degree of automation and optimizing their processes.

Multivac, for example, offers its customers innovative technologies that ensure among otherthings that as little film waste is generated during production as possible, marketing managerValeskaHaux explains.This is achievedwiththe aidof advanced machine tools, she continues, citing cutting tools as examples. The integration of handling modules in the packaging line as well ensures package-bypackage quality control for maximum consumer protection, says Haux.