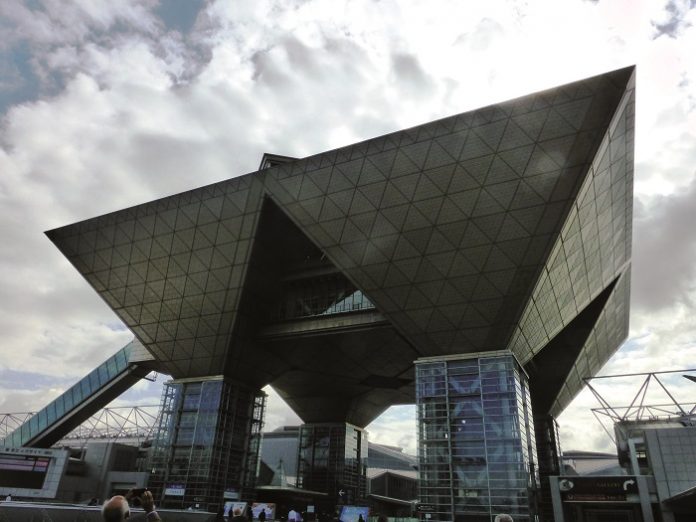

Tokyo Pack 2016 runs between 4 to 7 October at Japan’s international exhibition centre Tokyo Big Sight – a top regional show which this year styles itself as ‘The Heart of Advanced Packaging Solutions in Asia’ and promises a feast of inspirational technology and

design for resource-aware and consumer-focussed packaging that aspires to nothing less than perfection.

Europe finally is facing up to the same stark environmental and economic realities of producing goods in increasingly massive volumes that Japanese industry accepted more than two decades ago and has shaped Japan’s resource-aware approach to packaging production and design. Trailing behind but with Japan’s experiences to learn from, Europe now has an action plan and measures to nudge the Union’s 28 countries – or at least 27 of them – towards a manufacturing model based on a circular, rather than linear, model.

All business activity in Japan since 1990 has been based on Circular Economy (CE) principles and governed by the idea that waste from one process can be used as feedstock for another, commonly known as secondary raw materials. A shattering earthquake back in 2011 and economic and legislative forces lie behind a continuous effort to significantly reduce the volumes of packaging material consumption while adding value to both product and pack. With Japanese industry under pressure to guide consumer demand and obliged to pay weight/volume recycling fees known as Producer Pays or Extended Producer Responsibility (EPR), packaging has become ever more easy to separate into its component parts for sorting and discarding, and the aim is to lighten the financial burden of material disposal. Such targeted technologies and systems will be seen at the Tokyo Pack 2016 with many based on foreign expertise, which the Japanese companies openly welcome.

The main sectors covered will be Food and Beverage, Confectionery and Bakery products, Pharmaceuticals and Cosmetics, Non-food Consumer Goods and Industrial Products. Featured related services will include Packaging Materials, Printing, Testing and Inspection; Logistics and Distribution; and Recycling and Disposal. Historically, visitor attendance numbers are impressive – 179,000 in 2014. Of the 665 or so exhibitors, 20% of the total came from 15 countries outside Japan, including Sweden.

Japan is the world’s third largest economy and Sweden’s second largest export market in Asia, good reason for a Swedish pavilion at Tokyo Pack. Business Sweden, which promotes global trade, and research forum Packbridge, will be highlighting Sweden’s presence with a seminar programme. Topics include consumer insight, developments in flexo printing technology, communicative packaging and digital monitoring of food security, all of which are of high interest in the Japanese market.

Nefab, PLM, Tetra Pak, including a series of products of Akerlund and Rausing, a number of epoch-making inventions in the packaging field, produced in Sweden, have enjoyed wide success in the world market. In addition, the packaging field of electronics of Cypak, freshly brewed coffee for the packaging concept of OneCafé, such as instant food for system technology MicVac, new innovative companies will not appear one after another. OrganoClick has developed a technology to produce a new characteristic to strengthen the cellulose fibre, Xylophane aims to make the barrier film from a renewable material.

Sweden is one of the world’s largest paper and pulp producing countries, and offers the expertise of packaging based on fibre including healthy and sustainable solutions for the packaging of building materials such as cement and Plaster of Paris and food materials such as milk powder. New materials, and in particular fibre composite materials, used in conjunction with coatings and films made of starch, gluten such as Xylan all move towards the development of renewable materials, such as Xylan.

Research has been energetically continued and Sweden’s sustainable forestry yields some very strong paper solutions that are an alternative to plastic sacks both for bulk packaging and even for air-tight and insect proof dry foods as well as paper based cartons. SustainPack EU which has funded several projects is a large-scale industry-university research initiative on sustainable packaging while STFI-Packforsk of Sweden, an internationally renowned research and development institution are to coordinate the whole.

Holistic approach to packaging

Sweden has focussed on designing a package with the highest performance and functionality throughout the life cycle of up to reuse from the manufacture of the product. To do this, as in the simple packaging of Ikea of Tetra Pak, the systems use a minimum of resources. The Business Sweden seminar will also discuss the power to design the efficient delivery of packaging.

Seminar programme

Packaging and the ECOnsumerm Mikael Lindström, Innventia Latest developments in flexo printing technology, Ulrik Karlsson, Mondi Sunne Communicative packaging, Kristina Brink, Anna-Sara Fagerholm, Mid Sweden University Packaging Design – Consumer perception, Helen Högberg, Kostym Designinudstries Innoscentia – digital monitoring of food security, Robin Thiberg, Innoscentia Packaging trends and Open innovation for packaging tech development, Johan Mårtensson, Packbridge Packaging – from environmental villain to hero, Helen Williams, Karlstad University