Kodak Flexographic Packaging Solutions’ general manager and vice president Christopher Payne and its marketing and communications director Emma Schlotthauer stopped by in India to meet packaging printers and converters, and perhaps to assess the recent progress of the company in the flexo market here. To some extent the visit represents the new Kodak based on a restructuring or makeover around drupa 2016, when the company announced its intention of divesting its Enterprise digital printing systems business comprising the Prosper and the new Ultrastream ink jet heads and systems, and focusing on its prepress solutions, especially packaging. Naresh Khanna reports on the discussion.

In the past three or four years, Kodak has been able to break the Esko CDI monopoly in the Indian digital imaging market and now enjoys a footprint of nearly two dozen NX installations. Kodak India’s vice president for Flexographic Packaging Solutions Abraham S Prabhakar says, “Our NX systems now cover almost each and every trade shop across the country in all the geographic regions—East, West, North and South.”

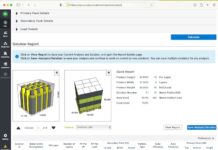

The NX digital imaging system is an indirect system where a laser first exposes a thermal image layer that is subsequently used to expose the photopolymer plate in a perfect vacuum in the absence of oxygen. The hallmarks of the NX flexo plates have been high quality reproduction using flat top dots characterized by a texture on the top surface of the dot. The sturdy dot structure of the plates provides a robustness with an overall ease of use for flexo printers coupled with better ink transfer, especially on solids and areas with high ink coverage and densities.

Ink transfer from plate to substrate is fundamental to flexographic print and Schlotthauer says that the company’s pioneering microsurface texturization of the dot really started as early as 2009, which eventually led to Kodak’s Digicap NX patterning. She points out that the textured dot surface solutions are not simple, “One texture doesn’t suit all types of image elements. Also, there are other variables such as ink type and anilox volumes. However, in designing a flexo imaging solution we have to look at balancing complexity with building a robust and lean system. Ease of use is also key.” At the same time, the company is about to release the new Kodak NX Advantage-6 solution, which will provide six

unique types of micro surface texturization to more closely target the variety of substrates and applications.

Security and simplification

Payne and Schlotthauer shared samples of flexible packaging printed with NX plates on CI wide web flexo presses. One of the key features was the legibility of extremely small microtype printed on a W&H wide web CI flexo press that can be read only with a magnifier. Payne said, “Not only is this a benchmark for flexo quality that is competitive with gravure, but this is also a way of embedding security features in flexible packaging without incurring any extra cost.”

Kodak has also been able to simplify its plate materials, which comes as a good news to flexo trade shops that normally have to maintain unique inventories for various types of flexo applications. Kodak’s NX flexo plates will now be usable for all types of applications although there will still be a special thickness for postprinting of corrugated materials.

Both Payne and Schlotthauer are convinced of the advancing efficacy of flexographic solutions. “It’s the most productive process,” they say. Their visit to Kodak’s customers across India echoes the company’s thrust in packaging and particularly in flexography, which they believe will also be adopted by the carton industry. They are keen to understand the Indian packaging market, which from their perspective may in fact be similar to Kodak’s experience in Latin America.

The DLE conundrum

Since we have continuously followed the development of direct laser engravers for flexo plates over the past several years, we took the opportunity to ask Payne and Schlotthauer about why this technology, which the company was initially enthusiastic about, is now consigned to the back burner. We had put up the same question at Kodak’s drupa press conference. However, Payne’s answer in Delhi was the same as at drupa, and perhaps still not wholly convincing considering how positive the company was about its DLE development at the previous drupa and at subsequent shows such as Labelexpo Brussels in 2013. Payne said that DLE is really effective for flexo plates in sleeve form and that this market is currently too small to sustain the Kodak DLE technology.

The case for direct engraving of flexo plates is nevertheless made by several DLE imaging systems in the market, such as the Hell Premium Setter, Lead Laser and Stork Helios. Moreover, there are seven suppliers of the elastomer (rubberlike) plates based on cross linked polymers, similar to synthetic rubber, that are directly laser engraved. While Kodak remains quiet about its DLE, Fujifilm, which too actively developed a DLE imager in recent years, has also withdrawn its own device and is instead selling the Hell DLE re-badged under its own name, designed to use FujiFilm’s plate materials. In India, Uflex has installed a Lead Laser DLE at its Jammu plant for use in conjunction with its F&K wide web CI flexo

press. In addition, two Indian manufacturers of rubber rollers—Arvind Rub-Web Controls and Gayatri Rub Tech—that we met at K in Dusseldorf are planning to produce sleeve materials for direct laser engraving of high quality flexo plates.