In the middle of March, Heidelberg and Masterwork presented the new Diana Go folder-gluer for the growing packaging market at an open house in MK’s European factory in Nové Město, Slovakia. Present among the European packaging printers were three who have already signed for the first three serial production machines.

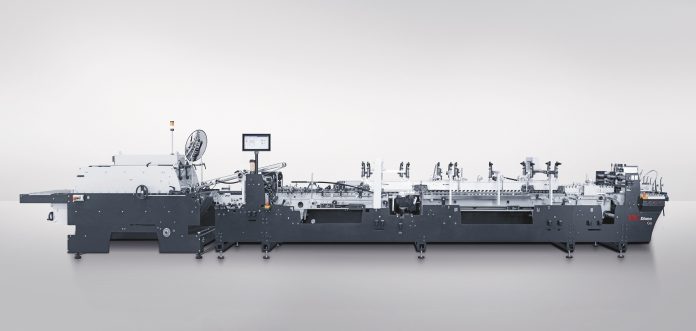

Developed on the basis of Heidelberg’s market requirements by the MK development team in Neuss, Germany, the Diana Go offers both commercial and packaging printers a cost-effective, flexible and productive entry-level machine with a comparatively small footprint. It can run a wide range of carton styles such as straight-line and lock-bottom as well as optionally special styles such as envelopes or CD covers. The just over 9 meters long Diana Go is able to hit a top speed of 250 meters a minute. The Diana Go is a good fit alongside the entry-level autoplaten EasyMatrix diecutter that Masterwork produces in its Tianjin factory.

The optionally integrated glue, inspection and ejector systems ensure high production quality. Designed for an expanded portfolio of products, the new folder-gluer is said to be attractively priced with the aim of achieving a good return on investment in very competitive markets. As a result of technology transfer, the Diana Go has many design features present in the high-performance folder-gluers of the Diana series.

Diano Go, Easy, Smart and X models

Coming less than two years after the introduction of the successful Diana Easy, the new Diana Go completes the portfolio of folder-gluers developed and produced by MK and sold and serviced by Heidelberg. The Diana Go is the entry-level compact solution; the Diana Easy is a general purpose machine with more than 30 machines sold in 18 months; the Diana Smart is a 450 meters a minute workhorse; and, the Diana X is the long established high-performance folder-gluer.

The Nové Město factory in Slovakia

The Nové Město factory in Slovakia, just 120 km northeast of Vienna, has a history of manufacturing equipment for packaging postpress applications going back more than 30 years. Originally established by Jagenberg company, the plant’s capacity was greatly increased by Heidelberg following its acquisition of the site in 2003. Operating under the MK Masterwork banner since 2016 with around 150 employees, the factory has undergone significant development.

MK Masterwork is the largest manufacturer of postpress equipment in the Asian region and has invested heavily in the manufacturing and R&D capacity needed to meet the demands of customers in the growing packaging market as the extensive development of the Nové Město site. The production capacity has been doubled since then to handle the demand for the new Diana Go as well for the existing Diana ranges.