Ever since, conventional UV has taken off in India, in particular for monocarton packaging where a 6-color plus coater with interdeck and end-of-press UV became a standard requirement, especially for the printing of board laminated with metallic polyester film (met-pet). In commercial print, Pragati pioneered UV coating for special effects. At present count, there would be approximately 60 to 70 brand new 6-color plus coater full UV presses in the country and perhaps as many as 50 similar presses that have been imported second hand. In some cases, presses were imported ‘UV-ready’ and retrofitted later, either with OEM curing systems or by Indian UV suppliers.

Although in recent times the conventional UV market in India for offset has been dominated by KBA and Heidelberg, with a few Komori and RMGT presses also being imported, in earlier days, Mitsubishi and manroland 6-color plus coater full UV presses were also imported. Commercial printers imported a number of 4- and 5-color presses with UV coating as well. Label printers using narrow web flexo presses contributed significantly to the growth and understanding of UV curing in the country.

As we have written earlier, conventional UV curing has become popular with Indian newspapers especially for printing outer jackets and supplements on high brightness or glazed newsprint. Indian dailies have been innovators in retrofitting UV curing lamps on top of 4 x 2 and 4 x 1 color towers let alone on 2 x 1 web offset presses using UV curing systems from the likes of IST, GEW, Prime and AMS. Thus, conventional UV for print and coatings has taken root in India in many segments (including screen printing and inkjet signage) in spite of the earlier apprehensions of the high cost of UV inks.

HUV, LED and ‘Multiwave LED’

There is growing interest in HUV and also in LED UV curing in India since the high heat, high energy requirement and high ozone levels of conventional UV make the overall operation and running cost of conventional UV prohibitive for many applications. There are four Komori dedicated end-of-press HUV running successfully for the past four years. There are another eight Komori UV-HUV combination interdeck and end-of-press curing systems running on multicolor plus coater presses for commercial and packaging applications. In these, the conventional UV bulb can be interchanged with the HUV bulb and the power consumption reduced by 75% in operation. The combination of HUV and conventional UV systems is gaining traction on more than 850 Komori presses installed globally.

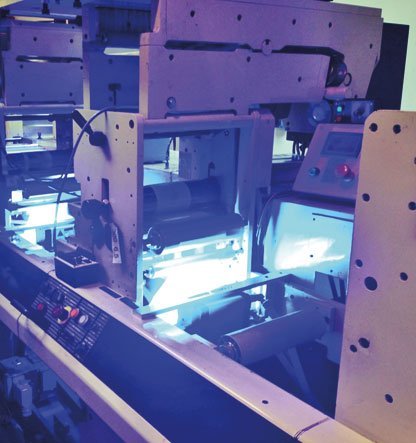

Impact Promotion is a commercial and short-run printer in Delhi who is using end-of-press LED curing based on a Panasonic LED lamp on his RMGT 920 press since February 2015. While this is a novel and stable solution, the price of LED inks and coatings is still a factor. At the PrintPack exhibition in Greater Noida in February this year, RMGT showed its 920 5-color coater press running a new technology called ‘Multiwave LED’ with Toyo’s Kaleido conventional UV inks. Multiwave LED essentially combines the narrow wavelengths that conventional UV actually uses (since a great deal of the conventional UV spectrum is wasted) together with the narrow wavelength of LED UV curing lamps that have already gained some traction. Both sets of narrow wavelengths remain active and the system remains as cool as the earlier LED lamps using 80% of the capacity of a 12-kW lamp.

The subsequent printing trials of the UV Energy multiwave LED lamp on several substrates including plastics using Toyo, DIC and Seigewerke inks have been successful both at Impact Promotion and at Lustra Print on their Ryobi 920 press. The advantage of this technology will be its ability to use the now less expensive conventional UV inks as well as the special LED inks that will take time to come down in cost. With either ink all the benefits of lower electricity consumption and cooler operation as well as a smaller size that would enable retrofitting are now available. The multiwave curing of LED coatings is still a work in progress but expected to bear conclusive and positive results within the April to June quarter of this year.

Key benefits of LED and multiwave LED are its compact size and low requirement for heat removal from the lamp. Secondly, the lamp can be instantly turned on and off (even between sheets as they pass through the press) so the lamp life is greatly extended, especially when the press is not actually printing. Experts suggest that a conventional UV is expected to last for 1,000 hours while the life of an LED UV lamp is normally rated at 20,000 hours.