Gold packaging created by Any

Graphics

Kuldip and Naveen Goel’s Any Graphics was already a well-known and award-winning label printing business when its new plant in Noida’s Sector 65 was commissioned in 2010. The company was known not only for printing high quality award-winning labels using digitally imaged letterpress plates but also for pioneering the production of dome labels – the specialized industrial 3D labels found as logos on numerous white goods as well as the back of Tata Motors Marco Polo buses.

The new factory with its glass office block also signalled Any Graphics’s entry in the carton business with a used but late model Heidelberg 5-color coater UV press and a Bobst autoplaten diecutter and folder-gluer. The high technology choices right at the beginning of their diversification to carton making indicated that the company was looking at delivering more than just pretty boxes.

to produce 3D visual effects by printing on Fresnel lens sheets

We remember Kuldip Goel showed us some of his value–added cartons even then. He spoke ambitiously of his blue ocean strategy of providing niche and creative packaging solutions – never thinking of himself as a printer or converter but as a designer. Of course, many printers speak about differentiation and value creation, but quite frankly very few are able to achieve or execute their plans as the father and son team at Any Graphics has, especially over the past four years that we have known them.

After a great deal of research and development of cartons in the early stages, the company was able to produce 3D visual effects by printing on Fresnel lens sheets but the costs were relatively high for most consumer product packaging. More work went into producing similar optical effects cost effectively using design and software techniques – by playing with the way the layers of inks and varnishes absorb and reflect incident light.

Horlicks Gold

Henko and other FMCG, pharma

and alcobev products

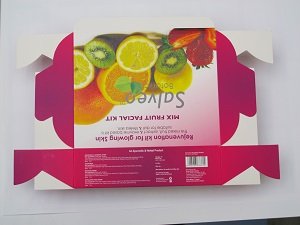

A major breakthrough came when GSK India wanted a 3D optical lens effect for their Horlicks Gold packaging. Any Graphics took on and met the challenge and several other consumer product companies beat a path to their door. The 3D lens effect was used for packaging Boost, Sensodyne and Henko and other FMCG, pharma and alcobev products. The company offered niche specialty cartons – customized solutions that included ease of filling and use and a range of visual, optical and haptic (textured) effects.

Value engineering of specialty cartons

By 2014, Any Graphics was ready for the next step – it ordered a brand new Heidelberg XL75 7-color plus coater press with interdeck and end-of-press UV curing that was up and running by May 2015. A new Bobst Novacut diecutter and an Amazon folder-gluer were also part of the expansion.

software is also good business

The new press is installed in an architectural environment – not just an airconditioned pressroom but what Kuldip Goel calls a studio and he is decorating and furnishing it as such. The new highly configured Heidelberg offset press is not a machine but a creative tool for the company’s continuous R&D for producing customized special effects on metallized and other boards. As Naveen Goel points out, “While the cartons must be visually stunning for shelf impact, many of the value-added effects also provide security from counterfeiting and they must be produced cost-effectively – and this is where we have become skilled at value engineering.”

Omet X6 ordered at Labelexpo 2015

At the recent Labelexpo Europe in Brussels, Any Graphics which earlier used slower letterpress label presses, placed an order for an Omet X6 fully automated flexo press. The 10-unit full servo 430 mm wide press has three diecutting units capable of producing labels, flexible packaging and cartons. While the Omet X6 has met the quality standards and ease of use tests, one can only guess at what the father and son duo plan to produce on this press. They say that flexography has hugely improved in the past four years and the market now demands volumes that can only be satisfied by flexo, their own ideas led them to buy a very specialized press.

When Any Graphics entered the offset carton business it went for a high technology configuration which it bolstered with the installation of its full UV 7-color Heidelberg XL 75. With similar boldness it has entered the flexo label and packaging segment with a highly configured and sophisticated press that is planned for installation in the first quarter of 2016. With a host of new product ideas in mind, the Goels believe that their passionate quest for creating and pioneering new visual and optical effects with the creative use of software and printing is also good business. “What is driving us is the technology – we first try to understand, acquire, absorb and creatively use it. Since we can demonstrate it as a cost-effective packaging solution, we are confident of creating and finding the customers

for it,” explains Kuldip Goel.