Toppan Printing, a global leader in communication, security, packaging, décor materials, and electronics solutions, has successfully collaborated with Unilever Japan. A company release dated end-January 2021 states that positive quality tests are leading to the adoption of Toppan’s mono-material for the “Lux Luminique Sachet Set Limited Design,” flexible packaging sachets due to go on sale in Japan from April this year.

‘Less plastic. Better plastic. No plastic.’

With the problem of plastic waste receiving significant attention, demand for more eco-friendly packaging continues to increase. Companies worldwide are taking various measures focused on targets for better circulation of plastic resources used for packaging and containers. Unilever has announced global commitments for a waste-free world, aiming to halve its use of virgin plastic. It plans to help collect and process more plastic than it sells and ensure that 100% of plastic packaging is designed to be fully reusable, recyclable, or compostable. Unilever is transforming its approach to plastic packing through its – ‘Less plastic. Better plastic. No plastic.’ framework. It is making progress in this effort globally.

Switch to mono-materials

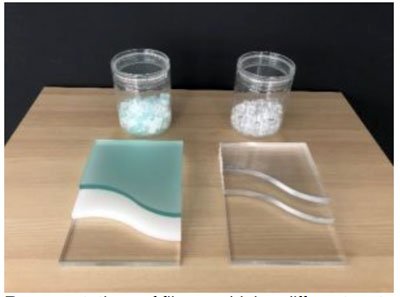

Toppan provides solutions to global companies addressing environmental issues such as global warming and plastic waste. ‘Sustainable-Value Packaging’ was recently launched as part of the ‘Toppan S-Value Packaging’ brand, which targets adding value for society and fulfilling living. The Sustainable-Value Packaging range includes more readily recyclable polyethylene terephthalate (PET) mono-material flexible packaging for individual packages. By fully leveraging vapor deposition and coating technologies accumulated over 30 years as a global leader in manufacturing transparent barrier films, Toppan has now worked with Unilever Japan to switch to a mono-material composition for individuals packages for liquid toiletry products.

Conventional individual packages combine a PET substrate with materials such as aluminum and polyethylene. Toppan’s mono-material packaging uses a PET-based grade of GL Film, a market-leading vapor-deposited transparent barrier film from the GL Barrier range, and combines it with PET sealant.

The manufacturing method and material composition ensure outstanding oxygen and water vapor barrier performance, provide low adsorption to prevent loss of aroma and quality, and make it possible to prevent the reduction of product weight during storage over long periods. The use of a single material improves recyclability, and the absence of aluminum film enables a decrease of roughly 25% in CO2 emissions during packaging manufacture.

“We’re delighted that Unilever Japan has chosen Toppan’s mono-material flexible packaging for these new products,” said Yoshimitsu Anamizu, managing executive officer of Toppan’s Living & Industry Division. “We continue to work on developing more readily recyclable and eco-friendly solutions for diverse packaging contents and aim to contribute to the growth of our customers’ businesses and a sustainable society by expanding the Toppan S-Value Packaging range.”