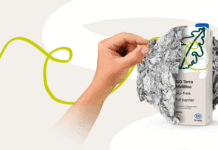

French family business Triballat Noyal is taking a future step by choosing SIG filling technology and aseptic carton packs for its Sojasun and Sojade plant-based products. Triballat Noyal, based in Brittany, likes to do things a little differently and is committed to making products that are healthier for both people and the planet. Choosing SIG filling technology for its plant-based dairy alternatives provides high flexibility and speed. The SIG CFA 812 filling machine, with an output of 12,000 trendy square base carton packs per hour, offers an unmatched number of packaging options for future product launches, yet also saves on utilities such as water and electricity. SIG’s sustainability roadmap also helped Triballat Noyal to make its decision. The team is fully convinced by key arguments in favor of SIG’s carton packaging, which gives Triballat Noyal the option to use industry-leading sustainable packaging materials. Initially for the French and Italian markets, Triballat Noyal will offer four new SKUs of its Sojasun brand soy drinks – Calcium, No Added Sugar, Chocolate and Vanilla – in SIG’s combiblocMidi…

Choose your subscription to read more

Trial

- ₹ 0 for 4 weeks*

PSA Plan 1

- ₹1,500.00 for 1 year*

PSA Plan 2

- ₹2000 for Year*

PSA Plan 3

- ₹3,600.00 for 2 year*