In the last week of August 2021, Elopak announced its Pure-Pak eSense aseptic carton with the aluminium layer removed. This improvement of the aseptic liquid packaging laminate is claimed to reduce the carbon footprint of the solutions by 28%.

The new aseptic carton solution retains the same shape as before and has the same barrier properties without the use of an aluminium layer in the laminate. Based on Elopak’s own technology the new solution is the same shape as the existing Pure-Pak Sense Aseptic carton and uses the company’s own technology. The implication is that the new aseptic liquid beverage cartons can maintain product integrity and safety over similar shelf life. The elimination of the aluminium layer means full recyclability for the cartons and hence a reduction of its carbon footprint.

Elopak’s Pure-Pak eSense

The new Pure-Pak eSense is the same shape as the consumer friendly Pure-Pak Sense aseptic carton, with the ‘e’ standing for eco-friendly.

It has been developed using technology from Elopak’s fresh portfolio that means the carton can preserve product integrity, safety, and lifespan without requiring an aluminium layer which is commonly used in aseptic packaging. The elimination of the aluminium layer results in a reduction of the carbon footprint of the carton by 28%, while facilitating full recyclability.

Commenting on the announcement Elopak CMO Patrick Verhelst stated, “Today brands and consumers are constantly looking for new ways to further reduce their environmental footprint, without compromising on functionality. We are excited to add this latest innovation to our offering and provide our customers in the aseptic segment with an even more sustainable packaging solution.”

“This innovation has been made possible because of Elopak’s decades of experience, the determination and efforts of our technical experts, and our company-wide commitment to advancing sustainability,” he continued.

The Pure-Pak eSense carton has been developed in line with Elopak’s ambitions to contribute to a net-zero circular economy. Elopak is on a mission to replace plastic bottles with fully renewable, low-carbon cartons that offer a natural, sustainable, and convenient alternative.

Setting out the importance of the development Elopak’s director Sustainability Marianne Groven stated, “Elopak is on a journey to become even more sustainable, both as a company and through the cartons we produce. Over time we have continuously improved the environmental profile of our cartons. For example, between 2014 and 2020 we achieved a reduction in the carbon footprint of an average carton with a closure from 32 gCO2e to 25 gCO2e.”

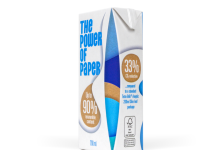

“Life Cycle Assessments have demonstrated that beverage cartons already have strong environmental credentials when compared to alternatives such as plastic bottles. They also play an important role in keeping products safe and minimizing food waste, which is a major source of greenhouse gas emissions.

The addition of the Pure-Pak eSense carton to our offering is important because it means our customers in the aseptic segment will also be able to select an aluminum-free option,” she continued.

“Aluminium is a finite natural resource, meaning it does not replenish over time. In addition, the extraction and production of aluminium is relatively energy-intensive and thus has a higher carbon footprint compared to the other materials in beverage cartons,” Groven explained.

Elopak already offers customers a number of sustainability-focused innovations such as Natural Brown Board cartons across both fresh and aseptic segments. These are renewable, recyclable, and have a lower carbon footprint per carton owing to reduced wood consumption and the elimination of the bleaching process.

Elopak also offers cartons without a cap for chilled beverages. The Pure-Pak Imagine carton is a modern version of the company’s original Pure-Pak carton, launched in 2020. Designed with an easy-open feature, it contains 46 percent less plastic and is available as fully forest-based.