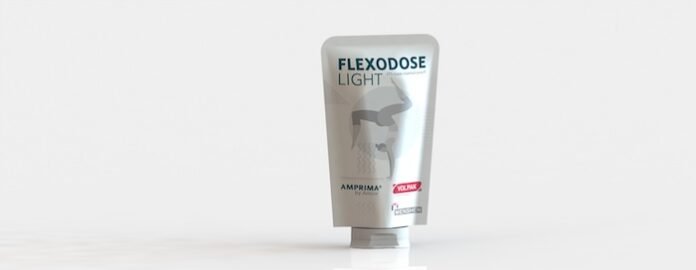

Volpak, a Coesia company and a leading global expert in horizontal form-fill-seal (HFFS) pouching machinery, has introduced FlexoDose Light, a next-generation inverted pouch format created in collaboration with Menshen and Amcor.

Featuring a distinctive wedge-shaped design, lightweight mono-material structure, and a precision-engineered spill-proof cap, FlexoDose Light brings bold visual impact, superior ergonomics, and a fully recyclable solution to market, meeting the evolving needs of modern consumers and brands.

Bold on the shelf, clean in use

With its angled, wedge-style structure, FlexoDose Light creates an eye-catching, self-standing display that acts as a powerful billboard at the point of sale. The flexible mono-PE structure ensures lightweight handling and compact storage across the entire supply chain from production lines to retail shelves and consumers’ homes.

The user experience is central: equipped with Menshen’s Lotus cap, the pouch guarantees spill-free, controlled dispensing and allows for easy emptying down to the last drop, with no product waste or mess. This makes it ideal for both everyday domestic use and on-the-go scenarios.

One pouch, many markets

FlexoDose Light has been developed for high-performance use across a wide range of product categories. In the food industry, it suits sauces, condiments, toppings, dressings, and dairy-based products like yogurts and spreads. In personal care, it’s a perfect match for shampoos, conditioners, gels, and lotions, while in home care, it accommodates detergents, surface cleaners, and refillable concentrated liquids. The common denominator across these segments is the demand for convenience, precision dosing, hygiene, and sustainability – all addressed by FlexoDose Light’s innovative format.

Designed for circularity

Environmental performance was a top priority in the development of FlexoDose Light. The pouch is made entirely from mono-material polyethylene (PE), including the film (by AMCOR) and the closure system (by Menshen). This makes the packaging fully recyclable and compliant with emerging global regulations on Extended Producer Responsibility (EPR) and plastic waste reduction. Compared to rigid bottles, this flexible format significantly reduces carbon footprint in both manufacturing and transportation, offering an eco-conscious alternative that doesn’t compromise on functionality or visual appeal.

A growing opportunity for brands

The global inverted pouch market is experiencing significant growth, driven by increasing demand for clean, user-friendly, and eco-responsible packaging formats. Valued at approximately US$ 12.8 billion in 2025, the global inverted pouch market is set to grow at a 7.7% CAGR through 2033. In North America and parts of Asia, inverted pouches already hold over 30% of the condiment and home care refill markets. As consumers gravitate toward packaging that is easy to handle, minimizes waste, and supports sustainable habits, manufacturers are shifting their packaging strategies accordingly.

A seamless fit into Volpak’s HFFS systems

FlexoDose Light is compatible with Volpak’s existing SI and SP series HFFS platforms, allowing brands to adopt the new format without the need for significant line redesigns. This compatibility extends Volpak’s long-standing focus on machine adaptability, production efficiency, and sustainability.

The cap and spout system, developed with Menshen, ensures safe and reliable reclosure even for viscous products. By offering an easy-to-integrate solution with strong environmental and commercial value, Volpak helps customers transition toward circular packaging with minimal operational disruption.