Fourth edition of CannovationMedium for reforms in tinplate packagingThe Tinplate Promotion Council (TPC) held the fourth edition of Cannovation, one of the premier events in Asia on tinplate packaging at Taj Lands End on 27 February 2015. Cannovation is a medium to push reforms in the field of tinplate packaging. Abhesh Chatterjee, chief of marketing and sales, The Tinplate Company of India (TCIL) said, “It provides a common platform to brand owners, can makers, metal packaging technology providers and marketers, with a vision to create a meaningful interface on the current and future needs of the metal packaging industry.” He added, “We are sharing the technological problems in tinplate packaging and trying to promote tinplate as the most eco-friendly, cost-effective and sustainable packaging media for processed foods. In India per capita consumption of tin is very low as compared to developed economies. So far we have a positive response from visitors and 25% growth has been observed as compared to the last event.”

The Tinplate Promotion Council held the fourth edition of Cannovation, one of the premier events in Asia on tinplate packaging in Mumbai on 27 February 2015Tarun Daga, chairman, TPC and MD of TCIL kick-started the day-long event

with his welcome address. Speaking about the merits of tin packaging,

NC Saha, director, Indian Institute of Packaging (IPP) said, “It is the

most adaptable sustainable packaging with exceptional barrier, aroma

retention, high-impact resistance and is completely recyclable.” He also

said that the tinplate industry has a growth of 6 to 7% annually in

India.

Ramaiah Muthusubramanian, category packaging development

director, Unilever said, “Tinplate is more relevant in today’s scenario

for three reasons — it can be used as a reusable pack; it works well as a

festive and promotional pack; and has a sustainable pack format.”

Ashwani Kumar, chief technologist for packaging and graphics, ITC India,

said that the packaging differs depending upon the region and stressed

on seeing packaging from a customer’s point of view.

Innovations in metal packaging

Saket

Bhatia, senior vice president, Hindustan Tin Works, expressed his

gratitude to the TPC team and said that FSSAI guidelines and food safety

issues emphasize the need for packaging but there is cut-throat

competition, reduced margins and brilliant minds get absorbed into

different sectors. He also said that converters should meet the decision

makers, marketing members and communicate with them about innovation in

metal packaging. Ease of opening and downgauging the thickness will

make it more preferable as a packaging material in food and non-food

products. He talked about inks which are well-known but not seen much in

the market, that is, thermographic and glow in dark inks highlighting

the brands. He also discussed about Rajniganda tin as an innovative

package by the company and mentioned its tagline, “Jab dusro ke khawab

purre karoge to apna kal bante dekhoge — so let’s work for them

(clients) and build our own future.”

Jeremy Pearce, ITRI

technology team leader, gave an introduction about tin packaging and

said, “Canned food has better nutrition for our children. A huge amount

of fresh foods are produced in India but about 40% of fresh foods in

this country is wasted. It never reaches the consumer, because it is

perishable and never gets transported, which is shocking. This is partly

due to culture — only 3 % of the food is sold through modern retail

outlets, 97% is sold through traditional methods. However, the solution

is very simple — robust containers containing nutritious foods can be

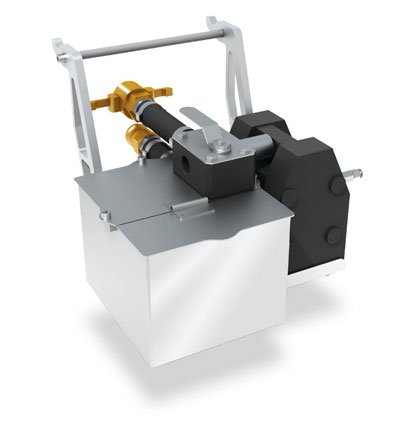

transported anywhere.” Jeroen Ruoff, director, and Simone Vooijs,

technical director of Tata Steel Packaging, Europe introduced a new

package, Protact, which combines the robustness of steel with the

versatility of plastic providing an even more efficient material for the

can.