By Stefan Hensel

The Internet and online commerce have transformed consumer behavior. The young generation of digital natives, in particular, has developed a strong preference for individuality over the anonymity of mass production. To meet the growing demand for individually prepared beverages, Krones developed ‘Bottling on Demand’ – a conceptual study for bottling lines based on the ACOPOStrak transport system from B&R.

Once the undisputed hub of the purchasing process, retail stores are playing an increasingly secondary role. Today’s consumers prefer to take shopping into their own hands – with the PC on their desk, the tablet on their couch or the smartphone just about anywhere else. They are not bound to brick and mortar buildings, nor are they restricted by business hours – the Internet is always open.

Yet, it seems that not even the virtually endless selection offered by online marketplaces is enough. They want personalized products made just for them – and they are willing to pay a premium to make that happen.

Individualization in the beverage industry

“We in the beverage industry have felt this urge for more individualization in our market as well,” says Andreas Gschrey, head of Digitalization and Data Technology at Krones AG. “And so we asked ourselves: Is there an economical way to implement small-batch production – even batch size one?”

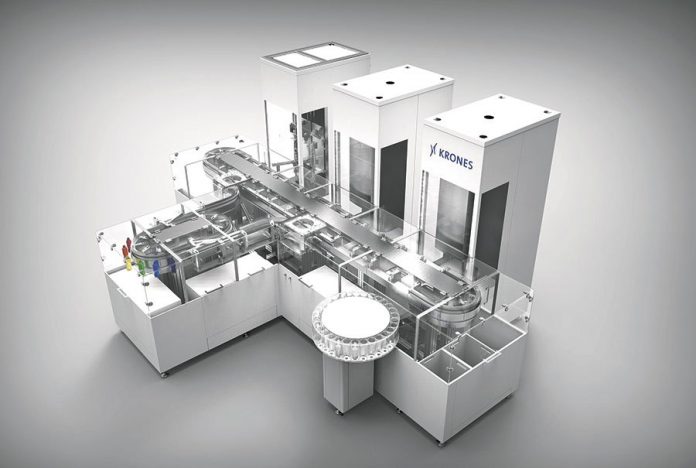

To find the answer, Krones built a conceptual study called ‘Bottling on Demand.’ The bottling line allows for the production of custom beverages that are made to order. Each beverage can be tailored to the customer’s needs in terms of content, bottle type, label, cap – or all of the above.

Independently controlled shuttles

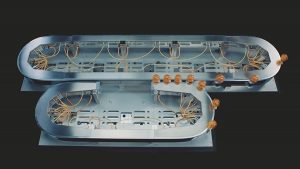

‘Bottling on Demand’ is built around B&R’s intelligent transport system, ACOPOStrak. Independently controlled shuttles move the bottles from one processing station to the next as they are filled, capped and direct-print labeled. The shuttles are servo controlled and are held on the track by magnetic force. The modular track segments offer virtually limitless flexibility and scalability in the design of the machine. Traffic control and collision avoidance are executed autonomously by the intelligent system software.

Photo Krones AG

“This is a completely new approach compared to the rigid timing of conventional conveyors,” explains B&R’s mechatronic technologies manager, Robert Kickinger. “It allows you to implement mass customization without any downtime for changeover. To fill a different recipe, you simply change how the shuttles and valves are controlled – physical retooling is a thing of the past.” At top speeds in excess of four meters per second, ACOPOStrak offers the potential to produce personalized products in mass-production quantities.

25 years of cooperation

Krones is one of B&R’s largest customers. Over the past 25 years, the two highly innovative companies have often joined forces to expand the limits of what is feasible in the field of bottling line automation. “Krones was one of the very first customers we approached with an ACOPOStrak prototype,” recalls Kickinger. “We were confident that Krones would recognize the enormous potential of this technology and be able to do something amazing with it.”

“In terms of bottling line design, ACOPOStrak opens up a whole new realm of possibilities for us,” Gschrey agrees. “With the combination of electromagnetic diverters, independent shuttles and virtually unlimited layout freedom, we’re able to implement parallel processing stations, buffer zones and anything else we need.”

Modular plants

“Bottling line requirements can vary greatly from customer to customer,” reports Gschrey. “And sometimes those requirements even change during operation.” The great flexibility afforded by ACOPOStrak makes it easy to implement modular machinery that each customer is able to arrange and rearrange on their own.

For its conceptual study ‘Bottling on Demand,’ Krones uses two oval ACOPOStrak circuits to test various approaches as they reinvent the bottling line for the future of individualized production. The goal is clear – “We want to build smart factory bottling lines, and we want to do it on a large scale,” says Gschrey.

New business models

“The waves that ACOPOStrak is making will reach beyond the manufacturing process,” emphasizes Kickinger. It will also revolutionize warehouse logistics. In the future, consumers will configure and personalize their products online and schedule just-in-time delivery – either for in-store pickup or right to their door. ACOPOStrak opens the door to entirely new business models in eCommerce.

The same principle even works in traditional retail logistics. A supermarket could have restocking orders triggered automatically, for example, as soon as a certain number of products has been scanned at the checkout. In effect, the production order goes straight from the cash register to the production line. The desired item is then produced in a precisely defined quantity and shipped immediately. “Inventory costs are reduced to an absolute minimum,” says Kickinger.

For now, Bottling on Demand remains a conceptual study, yet implementation in a series-produced bottling line could very well be in its future.

“ACOPOStrak-based bottling lines certainly have serious potential,” Gschrey is convinced. “One thing’s for sure – our question of how to implement small-batch and batch-size-one bottling economically has already been answered: with ACOPOStrak.”

Author: Stefan Hensel, Corporate Communications Editor, B&R