Structural Units (continued)

Registration Equipment

If tension were always constant in multi-color gravure rotary printing machines, once the registration was calibrated, there would be no register misalignment throughout the

process.

Because multi-color gravure printing machines layer each color individually to produce the image, however, there are several causes of register misalignment, so it is necessary to make corrections as each color is printed. These various factors cause tension variation between each of the printing units during printing, which leads to register misalignment. In other words, misalignment is caused by the change in length of the paper or plastic film web after it leaves one printing unit and before it arrives at the next printing unit. The following is a list of register misalignment factors, reduction methods, and preventative measures for tension variation.

Stretching and Contraction of the Web Caused by Drying Temperature

• Use automatic control of drying temperature

• Improve drying capacity at low temperatures

Stretching and Contraction of the Web Caused by the Printed Ink

• Stabilize printing pressure

• Improve precision of the printing cylinder and cylinder making

• Stabilize doctor pressure and doctor oscillation

• Control ink viscosity

Roll Slip in the Printing Unit

• Stabilize rotation of the guide rollers, cooling rollers, impression cylinders, printing cylinders, etc.

• Lighten the various rollers

Web flutter in the drying unit

• Relationship between the hot air blower nozzles and the guide rollers

• Balance air supply and exhaust

Static Electricity

• Stabilize the rotation of each roller

• Employ effective static electricity prevention and neutralizing measures

Even if theses measures are employed, there will still be fine amounts of tension variation. In particular, printing registration easily destabilizes during transient phenomena, such as acceleration, deceleration, and splicing. The degree of change is not constant and continually varies. Printing registration includes both lengthwise and crosswise registration

Lengthwise Registration

Methods of correcting lengthwise printing registration include those that use a differential gear in the printing cylinder drive system to correct misalignment of the printing cylinder phase and those that use a compensator roller located between the printing units to correct the web pass between the printing units.

A differential gear system is extremely convenient for adjustment of the printing cylinder phase during printing startup. If this system is used for registration correction during printing, however, it will affect the printing registration of the previous and subsequent units, so it is best to use a simple drive system that does not contain a differential gear

to maintain the precision of the printing cylinder drive longterm. The compensator roller method only adjusts the register of the immediate printing unit (strictly speaking, it does

influence the previous and subsequent units, but to a very small extent compared with the differential gear system), so is used for most printing machines, except for some special

machines.

In either case, if the operator observes and corrects the registration by eye, this will lead to delay in correction and difficulty in seeing the printing registration as the printing speed increases. Moreover, as the speed increases, the drying unit becomes longer, which further adds to the number of factors affecting register variation, making printing registration correction impossible. In this way, the need for automated registration equipment has come about.

For the operator to determine registration misalignment by sight, a register mark is included in the printing cylinders of each printing unit because registration is difficult to determine from the image. The operator compares the overlap accuracy of this mark to determine if registration misalignment has occurred. If one or more of the printing

unit register marks is misaligned, the image is misaligned by this degree, and it can be determined whether the cylinder is ahead of or behind the previous printing unit cylinder, or if it is shifted left or right. On the other hand, if the marks are perfectly overlapped, the image is also perfectly aligned. Automated registration control systems also require a mark

similar to the register mark.

There are two types of automatic registration control methods—standard color tracking and mark-to-mark. The standard color method uses the first printed mark as a standard and controls registration by aligning each of the printings of the following colors with the first printed mark. In this method, stretching and contraction of the web caused by tension variation becomes mark variation. Because variation is more severe in the later printing units, plastic film printing machines mostly use the mark-to-mark method, in which registration is controlled by comparing the current printed mark to that of the previous printed mark.

Compensator roller methods include those in which the roller is shifted in a fan configuration via circular motion to change the web pass and those that keep the wrap angle of the web constant while shifting the roller up, down, left, and right to change the web pass. In the former, the correction amount is small but variable. In the latter, because the correctionamount is always constant, the correction precision is high. In both types of compensator roller methods, it is necessary to ensure that the roller weight and web tension act in the same direction, that the corrective action is smooth with no resistance, and that the load torque in the drive unit is always applied in the same direction. The position of the compensator roller is limited given the structure of the machine, but the closer the roller is to the point of printing, the shorter the correction time.

In addition, to improve the registration precision of this system and stabilize control, an AC servo motor with good response that can immediately reverse direction and stop is typically used to reduce mechanical loss.

Registration Reproduction Device

After the printing cylinder is mounted in the printing machine, this device sets the position of the compensator rollers and each of the printing cylinders prior to the start of printing. In this way, the device configures the machine so that printing can be conducted with registration in a nearly calibrated condition from the start. This device either uses a method in which the position of the register marks on the printing cylinder in each printing unit is set at a constant position while the device shifts the position of the compensator rollers between each printing unit so that they are positioned at an integer multiple of the printing cylinder circumference (compensator roller method) or a method in which the position of the register marks on the printing cylinder in each printing unit is set at a constant position while the device shifts the mounting angle of the printing cylinders until the position of the register marks on each printing cylinder are synchronized (printing cylinder phase adjustment method).

In the former, the mechanical structure is simple, but there is a limit to the range of usable printing cylinder diameters, and in the latter, the mechanical structure is complex, but there is no limit to the range of usable printing cylinder diameters, giving both approaches strengths and weaknesses.

Methods that set the position of the compensator roller or the position angle of the register mark on the printing cylinders have changed from methods which required manual movement of the cylinders based on calculation of the numerical value of the printing cylinder circumference and the length of each printing point, to those where the operator simply inputs the printing cylinder diameter and a computer automatically makes the calculation and shifts the rollers and cylinders. By using these devices, it is possible to maintain the register mark within the control range of automatic registration to reduce printing loss and shorten printing startup times, which allows operational rates to be increased.

Printing machines that have a computer can recall the printing conditions from the previous job and reproduce a condition without registration error from the start of printing, record the best printing conditions, and apply correction depending on the printing conditions. In this way, computers help to greatly improve the functioning of the machine.

By combining this system with an automatic registration device having an automated gating function, registration can be calibrated in a very short time.

To ensure accuracy of the printing cylinder phase at the start of printing, a mechanism that can adjust the printing cylinder clutch in a stepless manner is required. As described in the section on printing cylinder drive systems, clutches that can be adjusted in a stepless manner have load variation and short-lives, so, in general, small module printing cylinder clutches that contain a gear with a large outer diameter are used to reduce phase error. Shaftless drive methods that use a separate motor for each printing unit can also be adjusted in a stepless manner. In particular, those where the printing cylinder and motor are directly connected have extremely little phase error. Another important point is ensuring a constant, unchanging web pass length between each of the printing units, which depends on the precision of the position and external diameter of the roller. In addition, it is also necessary to correct the web pass length by repolishing the impression cylinder.

Crosswise Registration

The mechanism of crosswise registration is similar to sidelay devices for the web in the unwinding and rewinding units, and a screw is generally used to make adjustments. Typical operational methods include those where the operator observes the registration and manually turns a handle to finely adjust the mechanism to the left or right. Compared with lengthwise registration, automation has not progressed very far. The reason for this is that the factors causing crosswise registration misalignment are far fewer than those that cause lengthwise registration misalignment, so it is sufficient to simply adjust the handle a little at the start of printing. Recently, however, there has been an increased demand for automation of crosswise registration along with the commercialization of labor saving, high-speed printing machines. Unlike register marks for lengthwise registration systems, automatic crosswise registration systems require register marks containing diagonal lines.

In either case, to improve the effectiveness of both lengthwise and crosswise automatic registration systems, tension stability is a prerequisite.

Drying Units

A major factor determining the printing speed of gravure printing machines is the drying capacity of the drying unit. In general, to increase the printing speed, the drying temperature or the dryer length must be increased, but these become causes of printing registration instability. In the case of stretchable plastics, in particular, important points

for designing an efficient drying unit are stabilizing printing registration and increasing printing speeds.

Drying Mechanism

Drying in gravure printing is the process in which heat energy is transferred via hot air, for example, to actively vaporize and remove the ink solvent from the oil-based ink or waterbased ink continuously being deposited on the printed matter from the printing cylinders. Heat energy transfer vaporizes the ink solvent at the surface of the printed matter, causing a vapor pressure gradient between the outside and inside of the ink, which drives the solvent inside the ink to diffuse to the outside as it shifts to the surface and vaporizes. Therefore, the two phenomena of internal diffusion and surface vaporization continue until drying is complete.

In the case of materials such as paper that easily absorb ink, the internal diffusion has a capillary phenomenon, liquid diffusion, and vaporization diffusion, so we only need to consider surface vaporization. If surface vaporization is too rapid, internal diffusion will not be able to keep up, so only the surface ink will dry. This will cause blocking and leave

behind residual solvent, so it is necessary to adjust surface vaporization. In this way, it is possible to increase drying efficiency by effectively adjusting the internal diffusion and surface vaporization, and controlling surface vaporization so that internal diffusion also progresses.

In general, we can assume this adjustment primarily depends on solvent vaporization in gravure printing machines.

The drying process requires the following items.

(1) Supply heat to facilitate solvent vaporization.

(2) Blow away and exhaust air from the boundary layer with printed matter having a high solvent vapor concentration to help vaporize solvent.

Although the ink solvent itself will vaporize if left alone, the solvent vaporization rate is faster at higher temperatures. As the solvent vaporizes, however, it absorbs surrounding

vapor heat and lowers the temperature, so heating is also necessary to make up for this heat loss.

Drying Unit and Heat Source

Hot Air Dryer: This drying unit uses a steam, electricity, gas, or oil heat exchanger that heats the air medium, so it is important for this method to effectively blow the hot air generated from the heat source against the printed surface. A blower is used to blow the heated air over the ink surface of the printed matter to raise the temperature of the printed matter, which increases the solvent vapor pressure inside the ink and facilitates solvent vaporization. Therefore, to increase the drying speed it is necessary to improve heat transfer from the hot air. The important factors in heat transfer using hot air are listed below.

Increase nozzle air speed: Blowing high-speed hot air against the printed surface to remove the saturated vapor boundary layer increases drying speed.

Reduce the distance between blower nozzles (increase the nozzle orifice ratio): Expanding the hot air contact area increases the heat transfer coefficient.

Decrease distance between blower nozzle tip and printed surface (web): The factor that has a direct influence on the heat transfer coefficient is not the speed at which the

hot air leaves the nozzle, but the speed at which the hot air contacts the printed surface (web). To prevent the speed of the hot air blown from the nozzle from slowing down, it is

best to bring the nozzles close to the web.

Efficient exhaust of hot air containing vaporized solvent: Rapidly exhausting the system improves the conditions for easy solvent vaporization.

Increase hot air temperature (increase within the range that will not change the physical properties of the printed matter)

An example of a structure that satisfies these items is the quick return hot air drying unit. The hot air nozzle shape factor is relatively large, the pressure loss is small, and the unit has a simple form. The exhaust system uses an exhaust tube orifice with a relatively small pitch that does not affect the hot air nozzles, but is able to effectively exhaust the hot air containing vaporized solvent. Moreover, the nozzle tips can be brought close to the printed surface (web) to maintain the air speed in effectively supplying the hot air.

By adopting this type of drying unit, it is possible to save energy (low air volume, air recycling), greatly decrease residual solvent compared with conventional dryers, and protect the environment by preventing the escape of solvent gas from the hot air in the drying unit. As such, this type of drying unit is used in most printing machines. In place of the conventional slit nozzles, drying units are increasingly using perforated plate nozzles that increase the hot air contact area, which raises the heat transfer rate by about 20 to 30%.

(a) Steam Heating

The heat source for hot air drying units typically uses steam because the running costs are relatively inexpensive, it is completely safe in terms of problems such as ignition, and temperature adjustment is simple.

(b) Electric Heating

Electric heating uses a sheath heater with fins as the heat source that exchanges the hot air to dry the ink. Although the facilities are simple, and operation and temperature adjustment are easy, the running costs are higher than other heat sources, so this type is only suited to low-capacity dryers.

(c) Gas Heating

The gas heating method includes direct and indirect methods. In the direct method, the air is passed around the gas burner inside the combustion furnace, which directly heats the air. In the indirect method, the combusted gas is separated from the air to be heated, so a heat exchanger is used to transfer the heat from the gas flame to the air to indirectly heat the air. In general, the direct method is often

(d) Oil Heating

This method is similar to the steam heating method, but the heating medium uses oil instead of steam. The oil heat medium is circulated in a sealed system and used indirectly, so there is little loss from leakage, flashing, blow down, and drainage, and because the electric power used during operations is very low, the running costs are also cheap. In

addition, this approach does not use water (steam), so it does not require a water treatment system or boiler cleaning agents,

making it easy to keep in operation. Among the many advantages, because the oil heat medium is used in liquid form, the piping diameter and heat exchanger are relatively smaller in size than when using steam.

(e) Hot Water Heating

This method is almost exactly the same as the oil heating method above, but uses hot water as the heating medium. Although the facility costs and maintenance costs are less

expensive than other heating methods, one must keep in mind that the hot air temperature is limited to a maximum of 80°C.

Heating Drum (roller) Dryer

The heating drum method has the highest heat transfer efficiency. This dryer, which uses hot air nozzles installed around a drum, was used in the earliest gravure printing machines for paper printing, but has not been used as the dryer for cellophane and plastic film. The reason for his is that there are problems with the difference in diameter with the printing cylinder given the need to drive the drum, the equipment is expensive, and if the plastic film is overheated the physical properties will change. As such, a drying method that does not excessively heat the film is used. In addition, when the machine is stopped the film may stick to the drum and the properties may change locally, so it is necessary to separate the film from the drum; the difficulty in doing so has become another reason that the heating drum method is not used. On the other hand, the method is recently being reconsidered for drying of water-based inks used with paper

Infrared Lamp, Far Infrared Tube Heater Dryer

There are three ways of transmitting heat—conduction, convection, and radiation—where conduction uses a solid and convection uses a liquid or gas as the transfer medium. Radiation does not require any type of transfer medium to transmit heat, but relies on electromagnetic waves that travel from high-temperature objects to low-temperature

objects. Therefore, in contrast to conduction and convection, which bring about waste from heating the medium and delay in transfer, with radiation the transfer of heat is direct and immediate. As such, infrared is assumed to be an extremely efficient heating method. In this way, infrared dryers heat the solvents in waterbased and oil-based inks from the inside, which prevents the ink from forming a membrane, so there is no ink membrane under which the solvent can remain.

Methods using an infrared lamp can heat the ink without raising the temperature of the plastic film much, so are effective for heating most inks, but depending on the color of

the ink, the heat absorption efficiency differs. In particular, black has a high absorption efficiency, but infrared has little effect on white.

Methods using a far infrared tube heater are less selective of the color than infrared lamps and have good space effiiency. In addition, the radiation heat from the tube heater also warms the inside of the dryer, so this heat can be used to blow hot air against the printed surface, allowing for dryers that use both radiation heat and hot air. Such dryers are often used.

High-frequency (radio) Induction Dryer

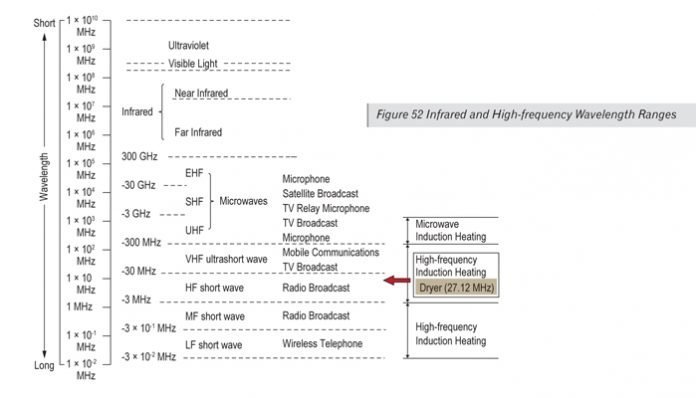

This method is called the radio-frequency-dryer (RFD), and uses the same principle as a microwave oven. When a dielectric body is placed in a short-wave (27.12 MHz) alternating electric field, the dipoles of the polar molecules attempt to orient themselves to the electric field, undergoing violent vibration-rotation at the same speed as the frequency in the process. The friction energy generated at this point causes the object itself to generate heat, which dries the coating film (ink) at high speed. This method does not require hot air and only generates heat in water-based ink (coating fluid) without generating heat inside the plastic film itself, so is being investigated as the most effective drying method (Fig. 52).

In any case, regulations under current fire laws, and such, mean that this method has not been adopted yet, but it is being reevaluated as a drying method for water-based ink.

Water-based Ink Drying

As described in the section on drying mechanisms, drying is different in the case of paper printing and plastic film printing In the case of paper, the porosity of the paper means it is easily penetrated by water, so drying problems are relatively easy to solve. The influence of water, however, causes major problems, such as a drop in paper strength, dimensional stability defects, paper wrinkles, and curling In contrast, plastic film does not absorb water and water drying is slow.

The drying energy of water-based ink is four to five times that of oil-based ink when water alone is used, while the drying energy is estimated at two to three times at a water/ alcohol ratio of 1:1. As such, drying problems are the largest issue for water-based printing.

To achieve similar printing speeds as with oil-based inks, ink manufacturers are researching methods that reduce the absolute volume of water transferred, such as increasing the concentration of inks and using shallow cell printing cylinders. Moreover, for drying units, there are also investigations into microwaves, high-frequency induction heating, and far infrared, while there are investigations into making hot air drying methods more effective, such as adjusting the air volume, air speed, nozzle configuration, and drying distance.

Blower

(1) Air Supply volume The dryer air supply volume must be determined in consideration of the lower explosive limit of the solvent gas contained in the ink.

When the air and solvent gas mixture ratio inside the drying unit reaches a certain point, the gas will become extremely explosive. This ratio has a range that is determined by the solvent, and even if the solvent gas is less or greater than this range, it will not explode. These are called the lower and upper explosive limits. The explosive limits for the solvents typically used in printing—toluene, ethyl acetate, and methyl ethyl ketone (MEK). To avoid explosion, fresh air is fed into the dryer to keep the solvent gas mixture ratio at one-third to one-forth the lower explosive limit, making this the minimum required air volume. In addition, the air volume equivalent to the total heat supply volume is the necessary air volume for the dryer.

Total heat supply volume (kcal/kg)=web heating heat volume + ink heating heat volume + latent heat of vaporization of the solvent + other heat volume (heat volume drawn out by exhaust + radiated heat from the outer wall of the dryer, etc.)

In addition, improving transfer is a prerequisite for raising the drying speed, but this also requires increasing the air speed from the nozzles. To increase the air speed from the nozzles, we can increase the wind pressure from the blower. The general equation for wind pressure P (Pa) is

P=P1 + P2 , P1=rV2/2

P1 : nozzle resistance (Pa), P2 : duct resistance (Pa), r: density of air at hot air temperature (kg/m2), V: hot air speed (m/sec) If we know air volume and wind pressure P=P1 + P2, then we can determine the blower capacity.

(2) Exhaust Volume

If the exhaust volume is not appropriate, solvent gas will leak from the entrance, exit, and gaps in the dryer, which will contaminate the printing room. This will also cause the drying capacity to drop.

In general, the exhaust volume is calculated to be 10 to 20% greater than the total air supply volume, while duct resistance from the dryer to the exhaust fan must be sufficiently considered when selecting the exhaust fan.

(3) Blower Types

The blower (air supply, exhaust) used in gravure printing machines is typically a sirocco fan, turbo fan, or blade fan.

Residual Solvent

Residual solvent refers to the tiny amount of solvent remaining in the ink film even after drying, and is believed to exist because of the coating film (solid content, such as pigment and varnish).

In the standard mechanism, when solvent vaporizes from the ink during drying, as shown in Figure 46, temperature rises until the ink and web are completely dried. The first period is the material preheating period.

Next, the solvent is vaporized from the ink surface. This is he constant rate drying period and lasts until the ink loses its fluidity. During this period, the vaporization rate is at its

highest.

In addition, from the point that the majority of the solvent is lost, the ink loses its fluidity, and the ink adheres to the web, the solvent diffuses inside the coating film. This is the

lapse (decreasing) rate drying period.

In terms of drying, the constant rate drying period is a chemical process, and is the step that limits the speed of solvent vaporization from the surface. Once in the lapse rate drying period, which is the step that limits the speed of internal diffusion, however, the vaporization rate becomes completely irrelevant. Residual solvent is a problem of the internal diffusion rate limiting step.

Internal diffusion is a physical mechanism, so is unrelated to the chemical vaporization rate.

Residual solvent volume is strongly related to the thickness of the coating film and the solvent desorption property, so cannot be calculated using simple drying theory.

Therefore, at this point, residual solvent volume can only be determined through measurement.