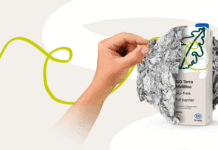

Markem-Imaje, part of Dover (NYSE: DOV), recently announced the release of the new 5940 G Touch Dry high-resolution inkjet coder. The GS1-128 compliant system meets growing industry demands for sustaining high-resolution barcodes, branding, and text on corrugated packaging without incurring the high cost of labels. It also reduces the need for pre-printed corrugated packaging.

The new system features Markem-Imaje’s proprietary Touch Dry inks that instantly dry on contact, enabling increased readability of GS1-128 barcodes for more reliable traceability. In addition, unlike liquid inks, Touch Dry inks will not spread along corrugated fibers and lose resolution. These inks, which are available in a variety of colors, are VOC-free, safe to handle, and support sustainability.

Applicable for a broad range of materials, the 5940 G prints highly scannable barcodes on corrugated cases and trays of fresh produce, beverages, meats, confections, and many other foods as well as precision printing on polystyrene for frozen foods and shrink wrap for pallet shipments. Further, the system prints clean, crisp information and codes on porous surfaces, including fabrics and non-woven materials for medical masks, gowns, and diapers. The system performs well in temperatures ranging from 32° F to 104° F (0° C-40° C).

The innovation also features patented Intelli’Flow printhead technology that helps avoid nozzle blockages due to ink backsplash and dust buildup. Additionally, it has a filtering process that effectively degasses the ink during printing and keeps the jetting mechanism clean and clear, resulting in higher print quality, greater throughput, reduced maintenance, and less downtime.

The system also supports increased throughput by enabling faster heat-up time by 67%. Also, each unit features from one to four printheads to support diverse and complex printing.

Supporting the printheads is a specially designed ink container, which is 75% larger than most competitors, helping cut operator intervention by as much as 43%. Ink containers can also be replaced without stopping production, and the 5940 G affords easy access to internal components, with parts quickly replaced within an average of 15 minutes from problem identification.

“The 5940 G system’s breakthrough Intelli’Flow printhead technology combined with fast-setting Touch Dry inks consistently achieves exceptional print quality of complex, compliant barcodes on corrugated and other difficult substrates, delivering a significant return on investment for customers,” said Greg Kasprzak, Senior Product Marketing manager, Markem-Imaje.

Furthermore, the 5940 G leverages Markem-Imaje’s packaging intelligence software to help manufacturers maintain their entire database of print jobs centrally, streamlining print management and supporting greater throughput.

“Markem-Imaje’s latest innovation, the 5940 G system, is all about delivering intelligence beyond the mark,” noted Kasprzak.

Markem-Imaje, a wholly-owned subsidiary of Dover, delivers innovative product identification, traceability, brand protection, and consumer engagement solutions to leading brands across the globe. The firm combines decades of advanced marking and coding experience with proven software and services to unlock the power of information in codes. Over 50,000 customers worldwide partner with Markem-Imaje to optimize coding processes, achieve compliance and protect their brands.