Structural Units (continued)

Printing Unit

The printing unit consists of a printing cylinder, an impression cylinder, a doctor unit, an inking unit, a drying unit, and a cleaning roller. In the case of multicolor printing, the

standard structure includes a registration device located between the printing units.

Printing Cylinder

The body of the printing cylinder is a machined steel tube with a high-precision finished outer circumference. After this surface is copper plated and polished, it is made into

a gravure printing cylinder. Finally, the surface is plated in hard chrome and polished again to prevent wear caused by the doctor. Therefore, compared to planographic and letterpress plates, the printing cylinder making process is fairly cumbersome.

Because the printing cylinder differs depending on the content of the work, the printing cylinder must be changed out often. As such, it is necessary to be able to exchange

the printing cylinders easily and accurately. Because the printing cylinder itself is fairly heavy, auxiliary equipment to mount and remove the cylinders is necessary during change-out.

There are two types of printing cylinders, one in which the cylinder and shaft are integrated and one in which the shaft can be inserted and removed from the cylinder (mandrel

type). In terms of strength and precision, the integrated type is superior, but for flexible packaging gravure printing where many printing cylinders must be stored, mandrel types are more common given the ease of storage. Moreover, cylinder change-out is regular, so operability is prioritized and thin-walled steel tubes are used to lighten the printing cylinders. The wall-thickness of these printing cylinders is typically around 5 mm for lighter cylinders, but if we consider deflection during impression, with plastic films the wall-thickness should be greater than 7 mm and with paper greater than 10 mm given printing precision concerns.

Furthermore, because these are only one-third of the weight of steel tubes, for purposes of operability, aluminum tubes are also used as printing cylinders. Given issues with printing cylinder making and the low yield point, these seem to have shortcomings in terms of their durability under high printing pressure.

In general, mandrel types are commonly used, so machine manufacturers simply supply the printing cylinder shaft or taper cones, while the printing cylinder user supplies the printing cylinder itself.

The printing cylinder structure includes taper cones that lock in both sides of the printing cylinder shaft. One side includes a gear used to rotate the printing cylinder, while the other includes a sidelay arm used to adjust the horizontal registration with the previous printings. The printing cylinder bearings are of two types, those in which the ball bearings roll inside a housing, and those in which there is no housing so that the printing cylinder shaft sits directly on top of the bearings. The latter type is designed to lighten the printing cylinder shaft.

The former is used for high printing pressure paper printing and the latter is used for low printing pressure plastic film printing.

Recently, shaftless printing cylinder mounting systems are increasingly being used to lock in the printing cylinder. This type is a mandrel printing cylinder with a locking method that locks in the taper cones using a bolt and nut, or a locking method that presses a taper cone against one side using a pneumatic cylinder.

Next, let us compare the taper cone shaft locking method with the shaftless method

Shaft Locking Taper Cone

Strength

• By setting the printing cylinder on the shaft ahead of time, cylinder change-out time is shortened.

Weaknesses

• Locking in the printing cylinder is difficult work.

• Printing cylinder runout is more likely to occur from the accumulated error of the components, such as the taper cones.

Shaftless

Strength

• Printing cylinder change-out work is simple and labor

saving.

• The printing cylinder is unlikely to have runout

Weaknesses

• Because the printing cylinders cannot be changed until after the machine is stopped, change-out time is relatively long. This is particularly true when taper cone changeout is required.

• The usable face length range of the printing cylinder is limited (because of machine strength limitations).

Areas of Attention for Printing Cylinders

(1) Adhesion of ink and debris on the taper cones and printing cylinder fl ange locking unit; angle of the taper section

(2) Fit of the taper cone key and printing cylinder fl ange key

groove

(3) Printing cylinder deformation caused by over-tightening

of the taper cones (printing cylinder strength insufficiency)

(4) Fit between the printing cylinder shaft and taper cone

inner diameter

(5) Cases where the printing cylinder shaft or printing cylinder itself has runout

The main point for gravure printing is the printing cylinder. It is no exaggeration to say that the quality of printing is dependent on the printing cylinder being used. The following lists some examples of printing defects caused by the printing cylinder.

i. registration defects, pitch defects and registration instability, pitch instability causes: inappropriate difference in printing cylinder diameters, printing cylinder taper, and printing cylinder eccentricity

ii. fogging causes (particularly with water-based printing): although the surface of the printing cylinder is plated in hard chrome to prevent wear from the doctor during printing and the surface polished until it is smooth, the smoothness of the printing cylinder surface in this case has a significant infl uence on “fogging.” This is because polishing can cause “swells” in the printing cylinder surface, so it is important to control the precision of polishing of the copper surface and chrome surface of the printing cylinder.

Other

More recent technologies are based on sleeve type printing cylinders. These thin, hollow cylinders used as the printing cylinder are pneumatically mounted onto and removed from

a cylinder that supports the printing cylinder.

Reinforced plastic and metal (aluminum, nickel, etc.) materials have been developed for the sleeve, and because these are light, change-out and transport are easy, while the storage area can be significantly reduced. On the other hand, these are limited in terms of printing cylinder circumferential length (printing pitch).

Difference in Paper and Plastic Gravure

Cylinders

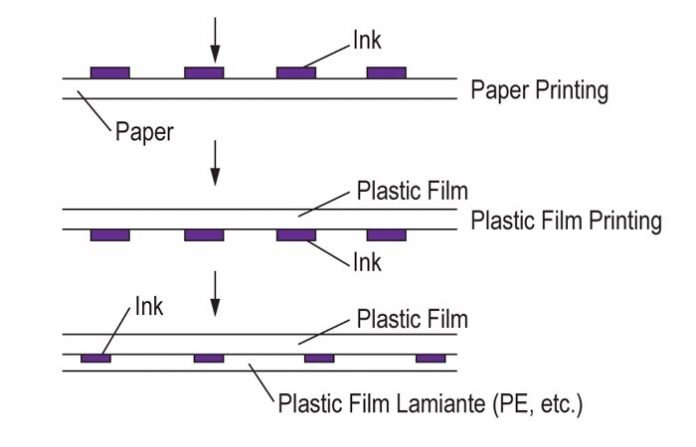

(1) Surface and Reverse Printing

The major difference between gravure printing for paper and plastic film is that paper requires surface printing, while plastic film typically uses reverse printing.

With paper printing, we are looking at the printed surface. With transparent plastic film, however, we are seeing the printed surface through the opposite side of the film, so it appears glossy and attractive. In general, another film is laminated to the ink surface after

printing so that the ink is sandwiched between the films. As such, regardless of whether the surface or reverse of the film is scratched, there is no risk that the ink film will be

damaged, which is one reason reverse printing is generally used. When using multi-color printing to create different colors, the order the colors are printed is reversed for surface and reverse printing.

Furthermore, when printing packaging made of simple plastic film, printing on transfer film, or printing polyethylene film, we use surface printing.

The printing order of reverse printed plastic film is typically black, cyan, magenta, yellow, and spot colors, with a final solid layer of white. In contrast, the paper printing order is

yellow, magenta, cyan, and black, with no final white layer.

(2) Plastic Film Elasticity

Unlike paper, plastic film has a tendency to stretch under tension. Although the film is printed in a stretched state due to tension during printing, the film returns to its original

dimensions after printing, so it is necessary to change the dimensions of the printing cylinders by this amount. Moreover, in the case of multicolor printing, there is the problem

of how to set the circumferential difference between the printing cylinders for each color. The reason for this is that a circumferential difference is typically set between the printing cylinders as a means of maintaining constant tension given that rotational resistance from the guide rollers and cleaning rollers between printing units, as well as heating in the drying furnace, affects the tension of the plastic film.

Therefore, the printing cylinder diameters are increased in each of the subsequent printing units. Although the optimal value for this diameter difference depends on the printing machine and printing conditions, the roller rotational friction of the newest printing machines is low and the drying capacity is higher, so a difference of as little as 0.03 mm is

used.

As a general rule, it is best if the printing cylinders are the same, but it is difficult to produce exactly the same diameter given processing issues. As such, it is best to have a

printing cylinder diameter that increases from the first color to the second color and so on to ensure registration stability. In the case of paper printing, too, the characteristics of

the paper require the printing cylinders to have different diameters.

Impression Cylinder

In gravure printing, after the ink in the pan is applied to the printing cylinder and a doctor used to remove the excess ink, the ink in the printing cylinder cells is transferred to the

paper or plastic film. Here, the method for transferring the ink relies on an impression cylinder. Because printing uses the pressing force against the printing cylinder, the impression cylinder must be strong enough to withstand this, and is thus made of a steel tube core wrapped in synthetic rubber.

As with printing cylinders, the impression cylinder is either integrated with the shaft or is a mandrel type. Although integrated types are desirable in terms of precision, and thus commonly used, mandrel types are often used in small printing machines, such as those for printing narrow rolls of polyethylene film.

In general, steel tubes are used for the impression cylinder core, but aluminum and carbon fiber reinforced plastic have come into use as a means of lightening the cylinders and improving workability during change-out.

The impression cylinder structure generally contains a single cylinder, but recently two and three cylinder turret type impression rollers have come into common use as a means of shortening the time required to change out the impression cylinder when the printing job is changed or when the roll width is changed. The size of the machine becomes large, however, and the structure complex.

With the impression cylinder structure mentioned above, the web must be cut when the impression cylinder is changed, but with sleeve type impression cylinders the web does not need to be cut when the cylinder is changed out. In place of the impression cylinder made of a steel core wrapped in rubber, mentioned earlier, this method uses a tapered metal core integrated into the impression cylinder lifting mechanism of the printing machine. A sleeve cylinder made of a reinforced plastic tube wrapped in rubber is mounted and removed from this core using pneumatic pressure. Because the impression cylinder does not include a steel core, it is light and can be easily changed out.

Although we will look at this in more detail in the section covering mechanisms that prevent sagging in the web resulting from the impression cylinder being raised and lowered, and in the section on the registration system, in short, this method uses a mechanism that maintains a constant web pass between each of the printing units when the impression cylinder is raised and lowered in addition to the initial registration reproduction system. There are also systems that aim to reduce printing loss when the machine is stopped.

The hardness of the rubber of the impression cylinder has a significant infl uence on the quality of the printed matter in terms of weeping, trapping, and sharpness. The rubber

is generally 10 to 15 mm thick, while an appropriate rubber hardness must be selected based on the type of printed matter. Generally, with plastic film, the Hs is 65 to 70, and

with standard paper and rough kraft paper, the Hs is 85 to 90.

In addition, the impression cylinder rubber must have resistance to the ink and solvents, so nitrile rubber (NBR) is generally used. Because the ink and solvents will differ depending on the printed matter, the rubber material must be selected based on these conditions. Additionally, the infeed and outfeed rubber rollers are the same.

The impression cylinder in the gravure printing machine does not have a drive gear as do other printing methods, but rotates via the pressure generated between the printing cylinder and the impression cylinder. This approach is advantageous in that it does not cause “gear patterns,” and allows the impression cylinder diameter to be selected in a

stepless fashion.

The raising and lowering mechanism and the printing cylinder pressing mechanism were originally mechanical methods, relying on manual or electrical power, whereas the printing pressure was determined by the printing nip width and the pressure mechanism was an integrated spring that relied on the elastic deformation of the spring and graduation lines for the unloading standard. Today, pneumatic and hydraulic pressure are generally used to raise and lower the cylinder and apply pressure. These methods allow for easy printing pressure setting and numerical control, achieving stable printing quality with no printing variation.

Printing Pressure

In the printing machine, pressure is applied between the

printing cylinder and the impression cylinder to transfer the

ink, but in this case, the rubber deforms and fl attens. This

nip width varies depending on the diameter of the printing

cylinder, the diameter of the impression cylinder, the rubber

hardness, and the printing pressure.

During printing, it is essential to bring the printing cylinder into close contact with the printed matter to draw the ink out of the printing cylinder cells. Physical conditions

during this process, such as surface tension and the capillary phenomenon, vary depending on the nature of the ink and printed matter. For example, the conditions for paper printing and plastic film printing are completely opposite. If the printing type changes, an impression cylinder with different characteristics becomes necessary, as does a different level of printing pressure.

The effective printing pressure for printing is not linear load, but is the load per unit area, so a narrower nip width is more effective than a wider nip width.

In practice, however, a certain amount of rubber deformation is required, so to achieve quality printing, a nip width of around 13 mm is generally considered necessary. When

the impression cylinder diameter is small or the printing speed is high, or if the printing pressure is high, the rubber deformation caused by printing pressure will cause a not able accumulation of heat in the rubber layer. This heat will then change the physical characteristics of the rubber, potentially causing shear or release.

Typically, plastic film is printed at a printing pressure of 1,500 to 3,500 N/m, but if the pressure is increased to 5,000 N/m because color thinning occurred, the impression cylinder will defl ect and a high pressure will only be applied at either edge if the pressure resistance is insufficient, which will cause further pressure decrease at the center, and further color thinning. Naturally, registration will fall out of alignment, and an arched shaped register defect will occur. This type of phenomenon is far more noticeable with wide

width printing and when pressure resistance is low, so we must be aware of the structure of the impression cylinder itself.

When printing pressure is high, as with paper printing, the impression cylinder will deflect so that printing pressure will differ between the center and edges, requiring us to use

a back-up roller in such cases. If we use a back-up roller, however, the impression cylinder rubber will be placed under high pressure from above and below, and as mentioned earlier, will generate heat, causing the rubber to deteriorate and the usable life to shorten.

To prevent these problems, water is sometimes passed between the impression cylinder and back-up roller as a cooling method.

To prevent the pressure decrease at the center of the cylinder mentioned above, we can use a mantel type impression cylinder (a structure in which the impression cylinder roller

and shaft are only connected at the center of the roller), but such rollers are extremely heavy, decreasing the workability.

In addition, we can give the rubber impression cylinder a crown to offset deflection in order to stabilize the pressurized nip width.

The crown can be calculated using beam theory, or chosen from an empirical value crown chart. Because deviation will occur depending on the nature of the rubber, the nature of the steel core, and the structure of the bearing method, however, it is best to calculate the crown degree from actual measurements. In this method, a pressure-sensitive paper or carbon paper is attached to the face length of the rubber roller. A load equal to the desired printing pressure during operations is applied and the nip width measured at three locations, the center of the roller and 50 mm from either edge of the roller. Next, let us calculate a crown using the following equation, which is based on these measured values.

C: crown, in other words, the difference between the diameter at the center of the roller and the diameter 50 mm from either edge of the roller (mm); W1: roller center nip width (mm); W2: nip width 50 mm from the edge of the roller (mm); D1: upper roller diameter (impression cylinder) (mm); D2: lower roller diameter (printing cylinder) (mm) When the result is positive, the crown is insufficient, and indicates the crown must be increased. If the result is negative, the crown is excessive and must be polished down by that amount.

Other

A state of pressure imbalance will also cause register defects, so after mounting the printing cylinder, we must check the horizontal level. In this case, we adjust the pressure, but when this type of adjustment is made during printing, it is likely to generate wrinkles and cause meandering, so we cannot expect a good printing precision.

the Stylus Method

If the impression cylinder is used for a long period, the ink and solvents may cause the edges of the roller to swell. If used in this state, the image from only that printing unit will be printed with a narrower width than that of the other printing units, and may produce the same printing phenomenon as the arched defect when the pressure is excessive. Because the surface of the impression cylinder is made of synthetic rubber, ink and solvents can cause it to swell and become easily damaged, so the rubber must be inspected and polished regularly. During polishing, we must be careful to avoid producing a taper in the impression cylinder, and in the case of multicolor printing, we must ensure that all of the impression cylinders have the same diameter. If the cylinder has a taper, the web will wrinkle and the width registration will easily destabilize. If the diameters of the impression cylinders differ, the length registration will easily destabilize.

Electrostatic Gravure Printing

The printing cylinder making process is so important that it is believed to determine the printing quality of gravure printing. The transfer of ink to the paper, however, is easily affected by the printing pressure and ink tack. If ink transfer is poor, the color reproducibility will be poor, and there will be color variation. In particular, “marbling” will be clearly noticeable in the highlight and halftone sections. The cause of the “marbling phenomenon” lies in the roughness of the paper surface. In short, because of surface roughness the ink in the printing cylinder cells and the paper will not come into contact with each other or the ink will not travel in the direction of the paper. As such, if we increase the printing pressure to bring the paper and ink into contact, this will reduce the occurrence of the “marbling phenomenon,” but if we apply too much printing pressure, this will also cause numerous problems, such as defl ection in the printing and impression cylinders or rupture of the rubber on the impression cylinder, so there is a limit to the printing pressure.

As such, the electrostatic gravure printing system was developed to solve this problem. This approach is based on an extremely simple physio-electric theory. Here, the impression cylinder rubber acts as a conductor, which is provided with an electrostatic charge using an electrostatic device. This improves the transfer of the ink inside the printing cylinder cells to the paper, which improves the printing quality and allows the printing pressure during printing to be decreased. As a result, registration becomes accurate and simple, allowing for high-speed operation of the machine.