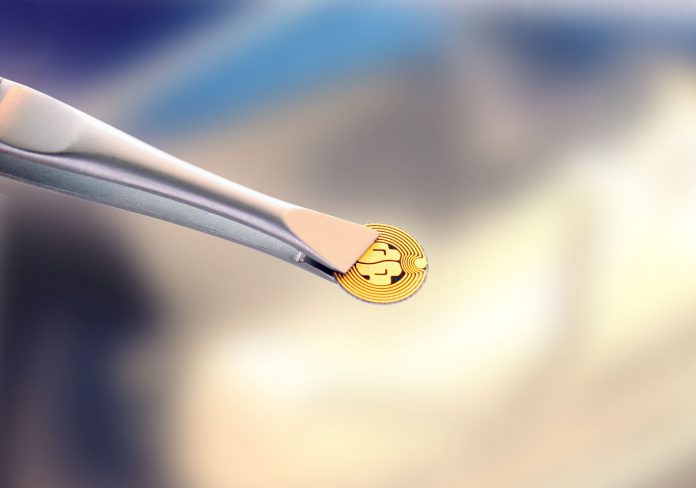

Rexam launched the first RFID-embedded plastic bottle for use by the prescription pharmaceutical market in the last week of March 2009. The injection blow-moulded HDPE container uses a patented technology that fully encapsulates radio frequency identification (RFID) components between injection moulded discs and then embeds the assembly into the bottle. This is the first application that uses an embedded RFID chip rather than an externally attached RFID tag.

The system can be used for bottle capacities of 40 cc and above and provide a more attractive option for traceability throughout the supply chain than barcoded labels.

Both Rexam and Owens-Illinois (O-I) were working on RFID embedded bottle concepts using different technology routes. Rexam had tied up with Traxxec to develop an ultrasonic process for welding the disc into a pocket on the base of the moulded bottle whereas O-I were working on their own process for directly embedding the disc during the moulding of the bottle.

When Rexam acquired O-I’s Plastics Products business in 2007