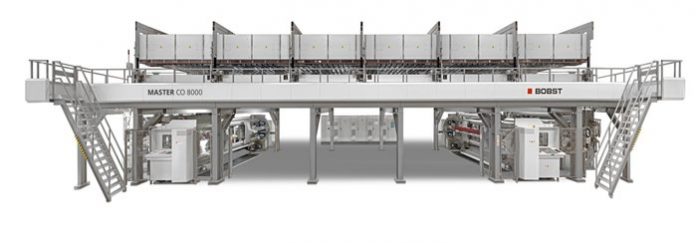

Max Speciality Films recently invested in a Master CO 8000 coating machine from Bobst to expand its barrier coating manufacturing capability at its plant in Nawanshahr in Punjab in North India. Founded in 1990, Max Speciality Films has grown into a leading supplier of specialty packaging including sustainable ultrahigh barrier solutions, and value-added products for labels, coating, and thermal lamination films for the Indian and overseas markets. Toppan which earlier had a 49% stake in the company increased it in February 2022 to make Max Specialty Films a consolidated subsidiary.

MSF is a state-of-the-art film manufacturer providing award-winning packaging solutions including the India Star and World Star awards and the coveted Golden Peacock Award for product innovation. It has had a long-standing relationship with Bobst for over two decades, in particular for the production of functional substrates and high-performance flexible packaging.

The company currently operates five Bobst vacuum metallizers with the recent addition of two Expert K5 machines – one equipped with the AluBond process and the other equipped with both the AluBond and the new AlOx GEN II processes. With substrate functionality and sustainability driving the industry, the trend to replace non-recyclable multi-layer packaging structures with mono-layer coated substrates that have high barrier properties is gathering strength at a fast pace.

The market needs metalized PET-type barrier performance on mono-material polyolefin-based substrates. This is achievable by combining an appropriate BOPP base film with the AlOx deposition process (AlOx GEN II). The transparent inorganic barrier layers allow for delayering from a triplex to duplex mono-material structures with embedded print and barrier layers, which can be beneficial for recyclability.

Navneet Malhotra, the head of the Max Specialty Film plant said, “We are looking forward to receiving the Master CO 8000 to further increase our production capacity. We have been associated with Bobst for over two decades and it was a very natural choice when we were looking to further advance in the coating section of the transparent barrier film market that is globally booming, driven by the current sustainability trend.

“With our goals and objectives in sight, our company has entered the next phase of its growth, propelled by innovation, capacity expansion, ‘best-in-class’ customer service, and rising equity in new markets for which investing in the new Bobst coating machine was apt for us at the time. We have been very pleased with the support from Bobst sales and services teams and choosing a Bobst machine again was an obvious choice for us.”

Bobst’s coating product line has specialist engineering know-how and experience covering the wide range of process technologies involved end-to-end in flexible packaging. Nilesh Pinto, Business director of Flexible Packaging for Bobst in the Indian subcontinent said, “We were very happy that Max Speciality Films decided to go ahead with Bobst yet again which honors our strong customer connection and bond extending over 20 years.”