DSM, a global science-based company active in health, nutrition, and materials, is launching sustainable, plant-based Decovery resins for the packaging industry. Starting with the Decovery SP-6400XP, with others to follow, this announcement paves the way for packaging producers to reduce their carbon footprint.

The print and packaging industry is constantly seeking materials that offer a lower level of VOCs and carbon emissions as these will help brand owners to fulfill their sustainability pledges. In recent years, DSM has realized that its Decovery plant-based technologies could offer much-needed improvements to sustainability to the packaging market.

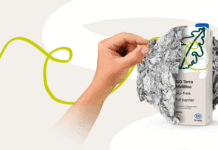

With the launch of the SP-6400XP – part of DSM’s Decovery range of resins for the creation of adhesives, primers, inks, and topcoats – DSM is helping brand owners to take a significant step towards meeting their environmental and sustainability pledges while also moving towards fully bio-based solutions.

“With our Decovery resins, we have enabled the transition to plant-based materials in the decorative, flooring, joinery and furniture markets,” explains Tim Gratzke, marketing manager Decovery at DSM Resins and Functional Materials.“This was only the beginning, the natural next step was leveraging our capabilities and experience to build sustainable solutions for packaging applications.”

New Decovery SP-6400XP is a low-NoAH alkali-soluble acrylic copolymer dispersion with high clarity and flexibility. It is particularly suited to adhesive application, such as removable paper labels for bottles and domestic adhesives.

It has a significantly lower carbon footprint than conventional, oil-based alternatives while also being highly flexible, meaning it can be deployed to adhere to a wide range of substrates. It is clear to view, non-tacky to touch, and will adhere to a variety of substrates, including glass and PET. At the end of its use, low temperature wash-off properties make SP-6400XP less energy-consuming in the recycling process.

Jacqueline Revet, global marketing manager of DSM Resins and Functional Materials commented,“People tend to appreciate the carbon-saving benefits of switching to, say, plant-based paints. But a lot of people are not aware of the difference that plant-based adhesives can make. When we reach the day when all adhesives are plant-based, we’ll save the planet 15 kilotons of carbon each year….that’s the equivalent of planting almost 250,000 trees for ten years.” Revet also added,“Adhesives are just the start. Imagine the environmental difference brand owners and manufacturers could make if primers, inks, and topcoats on their packaging could be plant-based too.”

Like DSM’s other Decovery plant-based resins, SP-6400XP is made from ingredients such as tree bark and castor beans that are sustainably sourced. All of these ingredients have been carefully selected by DSM to ensure they do not compete with the food chain in any way. Furthermore, these natural ingredients can be obtained and used far more sustainably than fossil-fuel-based materials.

As a result of their plant-based construction, Decovery resins contain zero-to-low VOCs, underlining DSM’s commitment to creating products that are kind to our planet and the people who inhabit it. However, DSM understands that while the packaging industry is eager for more sustainable products, consistently-high performance is essential. So SP-6400XP delivers a performance equal to DSM’s non-bio based NeoCryl BT-9.

With the launch of SP–6400XP, DSM is offering brand owners, formulators, and convertors a welcome opportunity to remove another layer of oil-based materials from the packaging production process.

Explanation of terms used

VOC

Volatile organic compounds. These are organic chemicals that have a high vapor pressure at ordinary room temperature. Long-term indoor exposure to VOCs is associated with health issues such as breathing problems, nausea, fatigue, and throat irritation.

NaOH

The molecular formula of sodium hydroxide (commonly referred to as ‘caustic soda’). It is used in starch-based adhesives. Highly corrosive in its solid form.

PET

Polyethylene terephthalate. A thermoplastic polymer resin of the polyester family. It is commonly used in clothing fibres, liquid, and food containers, as well as general manufacturing.

Royal DSM is a global, purpose-led, science-based company active in nutrition, health, and sustainable living. DSM’s purpose is to create brighter lives for all. DSM addresses with its products and solutions some of the world’s biggest challenges while simultaneously creating economic, environmental, and societal value for all its stakeholders – customers, employees, shareholders, and society at large. DSM delivers innovative solutions for human nutrition, animal nutrition, personal care and aroma, medical devices, green products and applications, and new mobility and connectivity. DSM and its associated companies deliver annual net sales of about EUR 10 billion (approximately Rs 89,466 crore) with approximately 23,000 employees. The company was founded in 1902 and is listed on Euronext Amsterdam.