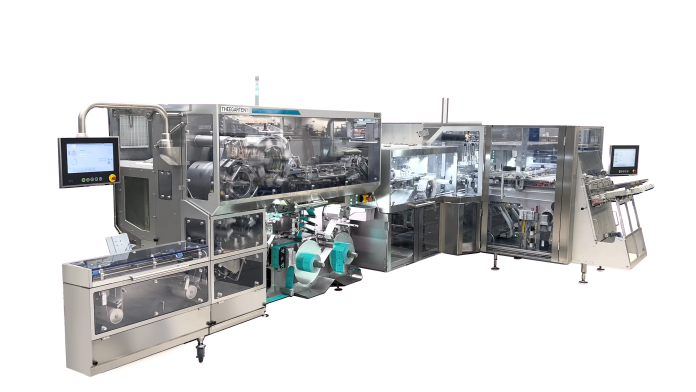

Theegarten-Pactec is a leading manufacturer of high-speed packaging machines for small-piece confectionery products. The company has also been developing and producing solutions for related products for several decades. Theegarten-Pactec is now expanding its portfolio with the new and innovative BHS high-speed machine for bouillon cubes. Impressing with an output of 3,000 packaged products per minute, the machine has set a new speed record. In addition, it is also setting new standards regarding economy, packaging quality, and hygienic design.

Boiled sweets, toffees, chewing gum, or even chocolate bars and pralines: when it comes to the fast and efficient packaging of these sweet treats, so-called small-piece confectionery products, the innovative Theegarten-Pactec solutions will inevitably be part of the conversation. Furthermore, for several years the packaging specialists based in Dresden, Germany, have also been developing and producing solutions for related products such as bouillon cubes. More than 250 machines are already being deployed worldwide for this special application. With its new development, BHS, the company is now introducing a machine to the market that promises to elevate the packaging of bouillon cubes to another level.

The machine, which is the result of intensive research and development work combined with the specialists’ technical expertise, makes use of the “continuous operation principle” developed by Theegarten-Pactec, which was previously intended primarily for confectionery packaging machines: there are no start-stop movements of the products within the machine during the packaging process, but rather a constant flow of movement. As a result, there are barely any acceleration forces acting on the products. In turn, this enables gentler product handling accompanied by a much higher output.

Cubes, double cubes, and tablets

Thanks to the reduced load on the product, the new BHS is also much less demanding in terms of the pressure resistance of the products. As such, the machine can also package soft bouillon cubes with just 30% of the previous minimum pressure resistance. Consequently, pre-formed cubes, double cubes and pre-formed tablets can be packaged gently and with maximum efficiency. Accordingly, the BHS is currently available in three versions, each impressing with a high packaging output.

The absolute top performer is the BHS for pre-formed cubes, which boasts a total output of up to 3,000 packaged products per minute. The BHS for double cubes manages 2,500 packaged units per minute, which corresponds to a considerable quantity of 5,000 individual packaged products per minute.

The BHS for pre-formed tablets also processes 2,500 packaged products per minute. Moreover, it can also be expanded with the addition of the BLM high-performance cartoning system, likewise, a Theegarten-Pactec development specially designed for direct connection to the company’s own high-speed machines.

Greater cost efficiency

In addition to its high output, the new BHS also scores points with customers on account of various other advantages offered. For instance, the BHS can be connected to existing presses for the manufacture of bouillon cubes and tablets from granulated foodstuffs without any problem. One production operator is sufficient for the operation of a line consisting of a press and a packaging machine. If the lines are positioned very close to one another, one employee can even operate two lines. In the case of the machine variant for the packaging of bouillon cube tablets, whereby the BLM cartoning system from Theegarten-Pactec can be connected, one production operator is again sufficient for the operation of the entire line consisting of a press, a BHS packaging machine, and the BLM cartoning system.

In addition to manageable staffing levels, numerous benefits also mean that the new BHS remains particularly cost-efficient throughout its entire product life. The system incurs barely any maintenance costs on account of the packaging machine requiring no lubrication, while oil changes are required at most once per year. What’s more, the BHS impresses with 50% lower energy consumption per packaged product when compared to other packaging machines.’

The ability to track machine parameters in real-time makes predictive maintenance much simpler, thereby minimizing the risk of fault-related downtime. The packaging specialists have also reduced the duration of required downtime to a minimum: with the BHS, entire assemblies can be easily replaced; flexibly, and quickly. Production continues to run efficiently with the secondary unit while maintenance is performed on the replacement unit.

Guaranteed product quality

Another point of focus during the design process for the new BHS was highly efficient quality control. This ensures that faulty products can be reliably sorted out prior to the packaging process, and insufficiently packaged products afterwards. Pre-formed bouillon cubes or tablets that are too soft on account of an incorrectly configured pressure within the press, the height of which does not comply with the specified parameters, or that are incorrectly positioned on the conveyor belt are identified as flawed. As a result, no products that could negatively influence efficiency or packaging quality reach the packaging process. The camera-based quality control system screens out already packaged products. This also applies if the printed image is incorrect or the folding is distorted, or if the packaging is poorly sealed (for example if it has protruding, open flaps).

This strict quality control ensures that only flawless products with perfect packaging reach the secondary packaging process. For example, if a fault repeatedly occurs, the cause can be quickly determined since all data about the packaging process is recorded. Consequently, faults can be easily pinpointed and quickly rectified. At Theegarten-Pactec, they are proud of the fact that, with their machines, the rate of qualitatively flawless products reaching the packaging process stands at 99.7%.

Improved machine design

With an improved machine design, the experts at Theegarten-Pactec also ensure better hygiene and process stability with reduced product contamination in the machine’s packaging area. For example, each product is only gripped once while unpackaged, thereby significantly reducing potential product abrasion.

The unpackaged bouillon cubes and tablets are also gripped in the lower section of the packaging process. Abraded particles are produced as a result of contact with the conveyor belts and the product grippers fall downwards. Because the packaging process is carried out upwards, abraded product particles do not make it into the packaging. Furthermore, each product is wrapped in packaging material just 80 milliseconds after having been gripped, which also minimizes abrasion. Bonuses regarding the “hygienic design” of the BHS are the paint-free design of the entire product area, the consistently implemented balcony construction, and the large panel elements that grant optimal access to the process using a simple pivoting motion. Consequently, customers from the food industry always receive hygienically flawless and reliably packaged products.

Stepping into the future

For the packaging specialists from Germany, downtime is a foreign concept. As such, at Theegarten-Pactec staff are already hard at work, further optimizing the new development. In the long term, both the BHS for double cubes and the variant for pre-formed tablets will also be capable of packaging 3,000 products per minute. What’s more, the innovation drivers are already planning the extension of the system’s range of applications to include, for example, the packaging of powdered milk tabs and cubes, as well as confectionery products.

However, pioneering developments such as these are only possible thanks to the customers’ commitment and cooperation. “In this regard, we have invested our long-term experience and a great deal of technical expertise,” sums up CEO Markus Rustler. “Innovation naturally entails significant development costs. We are more than happy to make this investment on account of the strong customer demand. We are the ideal partner for manufacturers that are pursuing clear objectives. Together, we are breaking new ground to continuously improve the packaging process.”