India’s largest multinational flexible packaging and solutions company UFlex has a strong focus on sustainability. Specializing in manufacturing and exporting packaging products it is committed to developing innovative and eco-friendly solutions in its chemicals business’ diverse portfolio which includes packaging materials, water-based inks, coatings, and adhesives. In addition, it offers solvent-free adhesives, UV, UV LED, and EB inks and coatings. These products have gained recognition for their sustainability practices, ensuring both high quality and longevity.

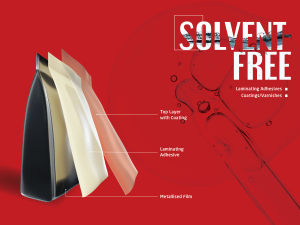

To meet the increasing consumer preferences in flexible packaging and their sustainability and cost reduction efforts, adhesive manufacturers have been compelled to innovate. The UFlex chemicals business has responded by offering solvent-free adhesives, which play a crucial role in providing converters with cost-reduction benefits and reducing volatile organic compound (VOC) emissions, while also enabling faster lamination speeds.

Among the key products offered by the chemicals business are solvent-free polyurethane laminating adhesives. These adhesives consist of 100% active components and do not require water or solvents as carriers. Primarily used in flexible packaging applications, they are available in various forms, including two-component adhesives composed of isocyanate and polyol, which react and form polyurethane. Additionally, we offer a one-component solvent-free adhesive based on NCO polyurethane, which reacts with humidity.

Solvent-free polyurethane laminating adhesives are applied to base substrates such as films or foils using solventless laminators, which can coat the adhesive via smooth roll transfer coating techniques. The coated substrates are then nipped and bonded to a secondary substrate to create the lamination. These laminations may contain multiple layers of laminate used to construct flexible packaging.

Flexible laminates in packaging are highly specialized products, combining several film/foil and paper layers with a variety of characteristics to achieve the desired features for each individual package, such as snack food, hot fill, boil-in-bag, microwavable, and frozen food packaging. These laminates also comply with a wide range of FDA regulations.

UFlex’s chemicals business continues to offer innovative and sustainable solutions that cater to the evolving needs of converters and packaging manufacturers. Its solvent-free polyurethane adhesive, known for its environmentally friendly properties, is specifically designed to provide several advantages enumerated below.

- Versatility in the formulation – The adhesive can be formulated to meet specific adhesive performance requirements, including bond strengths, heat seal strength, and product resistance.

- Operational safety and energy efficiency – The adhesive enables lower energy consumption during lamination, improving operational safety and energy efficiency.

- Lower raw material cost – The adhesive offers cost savings through lower raw material costs compared to other types of adhesives.

- Cost savings by eliminating ovens – Unlike water-based or solvent-based adhesives that require ovens to remove water or solvent carriers, the solvent-free adhesive eliminates this need, resulting in cost savings.

- Faster machine speed – The adhesive allows faster machine speeds, making it more economical for converters and increasing productivity.

- Improved Productivity – With its fast cure properties and longer pot life, the adhesive helps reduce lamination downtime, enabling converters to respond quickly and fulfil orders without compromising appearance and performance.

- Lower adhesive coat weight – The solvent-free adhesive can achieve the desired bond strength with a lower coat weight compared to solvent and water-based adhesives, reducing material usage.

- No VOCs concern – Since the adhesive does not contain organic solvents, there is no need for explosion-proof or warming measures during production, transportation, storage, and use. Additionally, it eliminates harm to the health of the operators. There is also no need to build specific solvent storage warehousing.

- The demand for fast-cure lamination adhesives with longer pot life is high among packaging converters as it increases efficiency and reduces lamination downtime.

However, despite the advantages mentioned, solvent-free polyurethane laminating adhesives also have certain limitations that hinder their broader success in the industry that are listed below.

- Slow cure rate at lower temperatures – Solvent-free polyurethane laminating adhesives tend to have a slow cure rate at temperatures below 30°C, resulting in a low-to-zero green bond. This limitation makes it challenging to laminate and slit inline during production.

- Poor adhesion with some laminations using water-based inks – Solvent-free adhesives may exhibit poor adhesion when used with laminations that involve water-based inks. This can impact the overall bond strength and reliability of the lamination.

- Dissolving effect with ink – In certain cases, solventless polyurethane adhesives may experience the phenomenon of adhesive and ink phase dissolution, particularly with dye-based inks. This can compromise the integrity of the lamination and affect its overall performance.

- Ultra-low migration of aromatic isocyanate in food applications – Solvent-free adhesives with aromatic isocyanates may have ultra-low migration levels in various food types, including fatty, aqueous, alcohol, and dry foods. However, in elevated temperature applications, migration concerns increase. As a result, these adhesives often require a longer curing time to meet FDA compliance standards.

- Short pot life – Solvent-free polyurethane adhesives typically have a short pot life, which refers to the time available for mixing and application before the adhesive starts to cure. The short pot life can limit the operational time and efficiency during the lamination process.

- Curing aspect – The curing process of solventless film-laminating adhesives is influenced by temperature and humidity conditions. Higher ambient temperatures accelerate the functional group reactions, resulting in a shorter pot life. On the other hand, higher humidity levels accelerate the curing reaction rate and may lead to volume expansion of the adhesive due to the release of carbon dioxide (CO2).

Monitoring the curing progress of solvent-free adhesives can be done using techniques like Fourier Transform Infrared Spectroscopy (FTIR). FTIR analysis can provide insights into the reaction progress over time by examining the NCO groups and the formation of urethane linkages. The weakening of NCO groups and the appearance of C=O stretching vibrations from the urethane linkages can indicate the progress of the curing reaction. The reaction speed may slow down after 72 hours as some unreacted NCO groups become encapsulated within the adhesive system, hindering further contact between NCO groups and OH/water

In our laboratory study, we investigated the impact of temperature and humidity on the curing behavior of a two-component polyurethane adhesive. The objective was to examine the effects of the environment on bond strength, toughness, failure displacement, joint stiffness, and failure mode. The study was conducted under various temperature and humidity conditions, including -20°C/12%Rh, -10°C/20%Rh, -10°C/30%Rh, and 25°C/45%Rh.

The results of the study revealed interesting findings. As the humidity increased from 12% to 45%, there was a linear decrease in bond strength. This indicates that higher humidity levels negatively affect the bond strength of the adhesive. On the other hand, increasing the temperature from -20°C to 25°C resulted in a reduction in curing time and an increase in bond strength. Higher temperatures accelerated the curing process and improved the strength of the bond.

It is important to note that the effects of temperature and humidity can vary depending on the specific type of adhesive being used. Different adhesives may exhibit different responses to changes in environmental conditions. Most literature references standard conditions of 25°C and 50% relative humidity for adhesive application, which aligns with the findings of our study as shown in Table 1.

Understanding the influence of temperature and humidity on adhesive performance is crucial for optimizing the application process and ensuring the desired bond strength and reliability. By considering these factors, manufacturers can make informed decisions regarding the selection and use of polyurethane adhesives in different environmental conditions.

| Conditions | Higher temperature | Lower temperature | Higher humidity | Lower humidity |

| Cure type | ||||

| Chemical Cure-Two component | Reduces cure time | Increases cure time | Little effect | Affects |

| Chemical Cure-One component | Reduces cure time | Increases cure time | Reduces cure time | Increases cure time |

Effect of humidity and temperature in polyurethane systems

Regulation information

Food safety is of utmost importance in the context of food packaging, and it requires special attention and adherence to stringent regulatory requirements. Adhesives, being an integral part of the packaging, need to be carefully produced to ensure full compliance with safety and regulatory standards. This involves careful selection of raw materials and meticulous formulation design to meet the required legislation for food safety.

The US Food and Drug Administration (FDA) regulates the use of adhesives in food packaging, and their approach differs somewhat from how they regulate other food contact substances. While FDA regulations for indirect food additives typically focus on the food contact substance itself, the requirements specified for adhesives place more responsibility on the manufacturers of food packaging containing adhesives and the manufacturers of the finished food product.

Under Title 21 of the Code of Federal Regulations (C.F.R.) Section 175.105, the FDA clears the use of various substances that may be employed in adhesive formulations intended for packaging, transporting, or holding food. As such, manufacturers of adhesive formulations can utilize any substance listed under Section 175.105(c) in their formulations, subject to any limitations specified for the use of those substances in the regulation.

The macromolecular structure of adhesives is formed through the chemical reaction of monomers. Both monomers and oligomers have the potential to migrate from packaging materials into food. When the amount of unreacted monomers or low-molecular-weight substances in food reaches a certain limit and is absorbed by the human body, serious health risks may arise (EU 10/2011). The toxicity level of these compounds depends on the fractional concentration of unreacted monomers. Isocyanates used in polyurethane polymers and adhesives carry a low risk of oral toxicity but a high risk of toxicity through dermal or inhalation exposure.

An example of newly formed Non-Intentionally Added Substances (NIAS) is Poly Aromatic Amines (PAAs) in polyurethane (PU) adhesives. PU adhesives are formed through the polymerization of polyols and diisocyanate monomers. If the adhesive has not been properly cured or if the ingredients have not been adequately mixed, the polymerization reaction may not be efficient enough, and any remaining non-polymerized aromatic isocyanates can react with moisture, resulting in the production of PAAs. In addition to PAAs, other NIAS can also be formed from laminating adhesives.

Overall, ensuring food safety requires strict adherence to regulations, careful formulation design, and proper curing processes to minimize the migration of harmful substances from adhesives into food.

UFlex solvent-free adhesives comply with the following compliances/global regulations:

- European Union (10/2011)

- EUPIA /CEPE

- REACH (1907/2006)

- REACH (SVHC’s)

- Swiss Ordinance on Materials and Articles SR 817.023.21

- FDA (21 CFR 175.105)

- Heavy Metals (CONEG)

- EC-standard safety of toys (EN-71 part -3)

- EC-Directive 94/62/EEC

- Latex and Natural Rubber with allergenic potential

- Mineral Oil Hydrocarbons [MOH] (C16 to C24)

- Benzophenones

- Phthalates

- Bisphenol-A Compounds

- Indian Standard – Food Safety and Standards (Packaging) Regulations – 2018 [Gazette Notification dated 24.12.2018, F. No 1-95/Stds./Packaging/SP(L&C/A)/FSSAI-2017]

- Food Allergen

UFlex Chemicals

UFlex Limited’s chemicals business, established in 1994 and headquartered in Noida, is a global provider of flexible packaging inks, water-based adhesives, solvent-less adhesives, solvent-based adhesives, and specialty UV and LED coatings. It offers a comprehensive range of UV and LED inks and coatings for sheetfed offset, letterpress, and narrow web applications.

As a leading ink manufacturer, the company prioritizes research and development, and its state-of-the-art R&D centre is NABL (ISO/IEC 17025:2017) accredited and recognized by the Department of Science and Technology, Government of India. Certifications for its Noida and Jammu plants, include ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 50001:2018, and ISO 31000:2018, demonstrating commitment to quality, environmental responsibility, occupational health and safety, energy management, and risk management.

The primary focus is on developing sustainable technologies, offering customized products, and providing food-safe, toluene-free compliant inks in accordance with IS 15495:2020 standards. It also provides on-site support to ensure optimal performance and customer satisfaction.