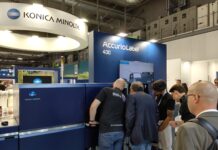

Konica Minolta recently installed its first AccurioLabel 190 press in the country, its state-of-the-art digital label printing solution at Hora Art Center based in Noida. The machine was sold by Reifenhauser India, which is partnering Konica Minolta in the label printing segment. The press is manufactured in collaboration with Grafisk Maskinfabrik (GM), a Danish company which provides the inline infeed, outfeed and converting technology that is also offered as a complete label solution. The AccurioLabel 190 is a replacement to the bizhub PRESS C71cf, a machine that was installed in more than 100 companies across the world post its launch a couple of years ago.

Pradeep Hora, managing director and Sanjay Hora, director of the company, Hora Art said, “We wanted a digital label printing solution which could help us to cater customers for short-run jobs. This machine from Konica Minolta is perfectly suited to our business needs as it offers faster speeds, better overall productivity and profitability.”

Ashok Sethi, executive general manager – PP & IP Sales at Konica Minolta said, “The growing demand for differentiated labels has made it necessary for print and printing businesses to look beyond the conventional, towards future-ready solutions.” The AccurioLabel 190 uses dry toner electrophotography at a speed of 13.5 meters a minute. It has three parts: a roll feeder, a print engine and a roll winder. The machine does not support hot melt media as it uses fusion technology to fix the toners to the substrate or label stock. It can print at speeds of 9.45, 13.5 and 18.9 meters a minute depending on the label stock type.

Ashok Sethi, executive general manager – PP & IP Sales at Konica Minolta said, “The growing demand for differentiated labels has made it necessary for print and printing businesses to look beyond the conventional, towards future-ready solutions.” The AccurioLabel 190 uses dry toner electrophotography at a speed of 13.5 meters a minute. It has three parts: a roll feeder, a print engine and a roll winder. The machine does not support hot melt media as it uses fusion technology to fix the toners to the substrate or label stock. It can print at speeds of 9.45, 13.5 and 18.9 meters a minute depending on the label stock type.

The digital label press can handle a wide range of media such as ordinary, matte, glossy, tack or synthetic paper and film with thickness between 60 to 250 micron. The maximum input width is 330 mm with a print size of 480 x 320 mm in normal mode and 320 x 1195 mm in banner mode. The AccurioLabel 190 is meant for operations such as small-lot printing, VDP and barcode printing. The press comes equipped with color adjustment software, which improves the quality of the output. At the same time, Konica Minolta’s R&D team is working to improve the color gamut that can be produced by the label press.

Speaking about the ROI of the machine, Shantanu Biswas, product manager of Reifenhauser India said, “If you run the machine eight hours a day for two years, your machine will be free. We’re getting a positive response from the market and are hopeful of a second installation soon.” Hora Art Centre is equipped with offset, narrow web flexo and digital printing presses including an HP Indigo digital label press which are capable of printing medium and long-run work. The KM AccurioLabel 190 press was acquired by the company to improve its short-run label printing capacity.