On 6 July 2017 at the new Wetzikon plant, which is a 30-minute ride from Zurich airport, Bobst and Radex announced the formation of a new joint-venture digital press manufacturing company called Mouvent. Also demonstrated at the launch were three digital textile printing presses and a new web-fed digital inkjet label press that was shown but will be demonstrated running at Labelexpo Europe in Brussels this autumn. Moreover, Mouvent is the company that will take forward all of Bobst’s ambitions in the digital arena, including the revamp of its digital corrugated press.

Founded in November 2013 by Radex as a startup, the company was converted into Mouvent as a joint venture with Bobst in 2017. Radex was founded by Piero Pierantozzi, Peter Brandenberger, Marcel Galliker and Walter Urech, each with more than 20 years of experience in digital inkjet printing. The same stakeholders were also the founders of Graph-Tech AG, in which Domino Printing Sciences initially invested in 1999 and eventually completely acquired in 2012. They sold it to Domino Printing Sciences in 2012.

With the launch of Mouvent, the new 80-employee company includes key personnel from Bobst and will focus on digital print in a pioneering way that actually uses 3D additive printing to build clusters based on Fuji Samba drop on demand (DOD) inkjet nozzles. As Jean-Pascal Bobst, chief executive officer of Bobst Group SA, said at the event opening, “Bobst has undergone a seven-year journey in search of the right partners, technologies and products to bring to its label, packaging and new segment customers.”

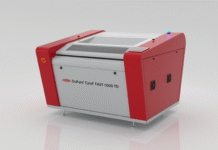

Mouvent’s first machine launched and demonstrated printing at Wetzikon is an innovative, highly productive digital printer for textiles, which prints with up to 8 colors, with a full product range and pipeline to follow. While the Mouvent label presses will be demonstrated at Brussels, the textile printers are already in beta testing and on the verge of shipping. “The first markets that we see for our textile printers are Turkey,

Pakistan, India and China,” said Bobst. Happily, one of the textile printers demonstrated at the launch will be shipped to India in the next couple of months. The highly integrated and lighter weight DOD cluster with its intelligent and compact design will be the center-piece of the new machines developed by Mouvent for a wide variety of markets such as textile, labels, corrugated board, flexible packaging, folding carton and perhaps others. Mouvent will become the digital printing competence center and solutions provider of Bobst.

“We truly believe this is a watershed moment for the future of digital printing independent of the industry or market,” said Bobst. “Current industry trends—including high demand for digitalization, short runs, fast availability, promotion and versioning, personalized and seasonal products, and increasing sensitivity towards cost and environment—are driving demand for high quality and affordable digital printing machines. Through Mouvent we aim to initiate a quantum leap in this area, ultimately providing the market with what it needs most—highly reliable industrial digital printing on different substrates at a competitive cost.”

As well as the digital printing presses, the first four of which were demonstrated and displayed at the Wetzikon launch of the company, Mouvent offers a fully integrated, complete solution; it develops, engineers, tests and industrializes digital printers based on the Mouvent Cluster. The new company writes the software around the printers, develops inks and coatings for various substrates, as well as provides a full servicing offering.

The innovative cluster design is the base building block for all systems, current and in development. “Our radical new approach is to use a base cluster, which is arranged in a modular, scalable matrix instead of having different print bars for different applications and different print widths,” explained Piero Pierantozzi, co-founder of Mouvent. “The Mouvent Cluster is the key technology behind the Mouvent machines, resulting in high optical resolution for a crisp, colorful, very high printing quality, as well as a never-seen-before flexibility and possibilities in terms of machine development. Simplicity is our engineering philosophy.”

Mouvent printers are extremely compact—taking their cue from and being closer to desktop printing than to traditional analog printers like flexo, making them very compact, light-weight and easily accessible. The modular, compact system allows easier settings and start-up with less fine adjustments required resulting in a productivity boost. The compact design has many other benefits, including a smaller footprint, faster change-over, simple implementation and lower cost. From our understanding and first look, they look truly scalable.

New compact concept for the corrugated press

Also key to the joint venture is its ground-up philosophy in which Bobst has all but abandoned the approach it talked about earlier of first building a 45-meter long continuous inkjet corrugated box printer based on Kodak’s CIJ technology. The new-found approach is from the ground up—starting from the smaller and more scalable, digital textile and label presses and then building the corrugated press which Jean-Pascal Bobst assured us would be far more compact than the earlier somewhat elephantine plan.

As the ever enthusiastic chief executive officer of Bobst explained to us, a key feature of all Bobst machines is their industrial reliability and the new heads have already been proven over 5,000 and 6,000 hours with the plan to make them last at least 10,000 hours over the next five months. Bobst’s strategy is to develop the inks for various applications and substrates in Mouvent’s own labs and then to engage major ink suppliers to supply the ink to its customers.

the Mouvent TX801 digital textile

printer at the Wetzikon launch on 6

July 2017. Photo PSA

Aware that his company is somewhat late to the market, Bobst is pleased to have found a promising and flexible technology breakthrough and business plan by starting a new joint venture. One can see his optimism about having all aspects of the technology in the new company’s control, which dovetails with the strategy to develop and hand over the ink supply to ink manufacturing companies. Reflecting on the competitive and chaotic market where thus far most inkjet technologies have not been able to really deliver profitability, he sees his new company and its ink strategy to get the ink makers to provide and sell the inks as disruptive. He feels that this is the way to establish viability in a competitive market that can be turned into a wider opportunity. “It’s my only chance,” he says.