Using nanotechnology can bring all kinds of benefits to packaging. AIPIA’s Andrew Manly

reviews some recent developments and looks at how consumer and regulatory concerns

are being met.

Thanks to their unique multifunctionality, a wide spectrum of nanomaterials is already in use for consumer packaging. In particular, the food and beverage industry has been a recent focus for nanomaterial applications and it has attracted a huge amount of money for research and development, including several EU-funded projects.

This flow of money is based on some very impressive forecasts of the market growth for food packaging containing nanotech. It is estimated that up to 400 companies around the world are developing possible applications of nanotechnology in food and food packaging.*

It is also clear that if consumers no longer want preservatives in their food then the industry is going to have to find other ways to extend shelf life. Nanotechnology offers the advantage that it is a chemical and gas free solution as an additive, substrate, coating or printed/deposited layer.

Growing market

According to a Persistence Market Research report ‘Global Market Study on Nano-Enabled Packaging For Food and Beverages’ (2014), the global nano-enabled packaging market for food and beverages is estimated to be growing at a CAGR of 12.7%, to reach about US$ 15 billion (approximately Rs. 105,000 crore) in 2020.

Why this rapid growth prediction? According to their white paper The Impact of Nanotechnology on the Flexible Packaging Industry and Ink Applications for Sun Chemical, Tom Donvito, and Rick Joyce say flexible packaging containing nano particles in various formats can provide barriers for gas, odors, moisture and UV light; improve structural performance; eliminate complexity in construction; reduce weight; and, add functionality such as track and trace. In effect, they say, nanotechnology will enable the next generation of flexible packaging innovation.

Research

Much of the latest research is on the antimicrobial properties of nanocomposites. NanoPack is a 3-year EU-funded project aimed at developing and demonstrating a solution for extending food shelf life by using novel antimicrobial surfaces applied in active food packaging products. Several partners from across Europe and Israel, including AIPIA, are involved.

Much of the latest research is on the antimicrobial properties of nanocomposites. NanoPack is a 3-year EU-funded project aimed at developing and demonstrating a solution for extending food shelf life by using novel antimicrobial surfaces applied in active food packaging products. Several partners from across Europe and Israel, including AIPIA, are involved.

The Nanopack technology consists in the encapsulation of essential oils with a naturally occurring antimicrobial activity into Halloysite nanotubes (HNTs), which are subsequently mixed with polymers to make packaging films. As the antimicrobial agents are released as a vapor from the packaging materials into the headspace, they can sanitize both the product surface and the headspace. The antimicrobial film is made by mixing the loaded HNTs with a polymer.

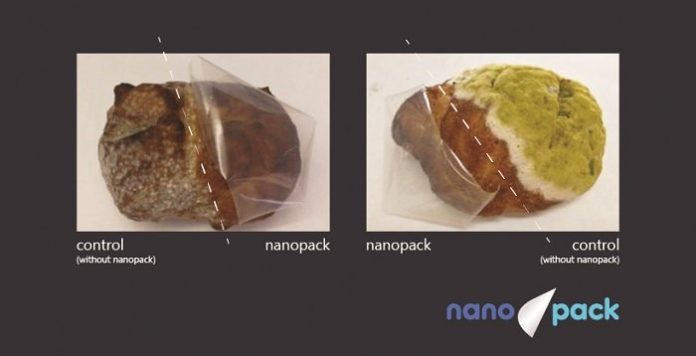

A first round of antimicrobial efficacy tests announced during Anuga Foodtec showed the film’s ability to inhibit mold growth on food-additive free bread. The sample had no mold growing in the area exposed for up to 27 days, post packaging.

Uniquely, the project also deals with the commercialization as well as regulatory and consumer acceptance of the film. Currently, there are not many activepackaging systems available, which could be related to difficulties in bringing

the technology to the market as well as regulatory barriers.

Scalable Sustainable Smart

In another project, led by Purdue University in the USA, a team, led by Jeffrey

Youngblood, a professor in the School of Materials Engineering, created a new

large scale manufacturing process using cellulose nano-crystals (CNCs) – derived from abundant resources such as wood and plants – as advanced barrier

coatings for food packaging.

The technique is scalable, as it is a roll-to-roll manufacturing process using waterborne polymer systems. CNCs are easily dispersed in water, so manufacturers

can control the structure and end up with only the properties that are needed for

the barrier material.

“The challenge for the food packaging industry is to create a recyclable and

sustainable barrier material that is low-cost,” Youngblood said. “Our innovation

is transparent, non-toxic and sustainable.”

Also in the USA, scientists at Clarkson University near New York have developed a low-cost, portable, paper-based smart label that can detect spoilage and

contamination of food and cosmetics, and provide easy to-read results.

Researchers have built a versatile sensing platform that incorporates all the

needed reagents for detection in a piece of paper. The paper is adaptable to different targets, including food contaminants, antioxidants and free radicals that

indicate spoilage. What makes the sensors unique are the nanostructures they

use to catch and bind to compounds.

Challenges

Challenges for nanotechnology in food packaging applications include developing materials that work as well as they should, meet health and safety requirements, and gain industry and consumer acceptance. Also relevant is the extra

packaging cost, even though active packaging is expected to prevent food waste

and, therefore, save money.

Another issue is possible migration, as quite a number of commercialized

forms of nano-food packaging are coated or composited product with inorganic

materials, for example, nanosilver and nanoclay. Concerns exist, in some studies, about the possibility of nanomaterial migration from packaging to foodstuffs,

particularly for silver. The debate is still ongoing among researchers about the

extent of migration and whether it is negligible and safe.

Security

Other areas of nano development for packaging include sophisticated security

measures. Nano-structured holograms from Schur Flexibles have built-in anticounterfeit features. The patented film concept allows the incorporation of a

unique holographic effect. There is no use of inks, varnish or solvents involved.

The hologram is made with nano-structured polymer melt imprinting, which reflects the light in specific colors and patterns to create the unique nano-structure,

which is created in the extrusion layer. They can be used on both transparent or

metallized backgrounds.

Way ahead

With so much research and commercial development in progress, only enabled

by huge amounts of investment, the way ahead for nanotechnology in packaging

seems sercure. There is clearly a need for it, and it is a catalyst for innvoative and

novel materials and printing solutions which are going to move the packaging

sector forward.

Cost and scaleability remain constraints, but these are issues being addressed.

And while regulatory issues and consumer acceptance are other potential barriers, it does seem, at least in Europe, that regulatory authorities are aware of the

benefits of using nanotech for food packaging.

Consumers are looking for ‘clean’ products. Nanotechnology offers them the

chance to have their cake and eat it!