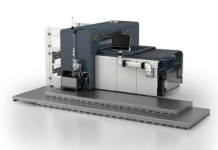

Koenig & Bauer and Esko, both global leaders in the field of packaging printing, recently agreed to further strengthen their partnership. To this end, color management and workflow solutions from Esko were installed at the Koenig & Bauer demo center in Radebeul and are available with immediate effect for live presentations to interested customers.

As a solution provider to the packaging industry, Koenig & Bauer sees Esko as a strong partner when it comes to process-integrated workflow solutions. Accordingly, it will show users the Equinox color management technology, which enables printing with an extended color gamut, with the necessary RIP architecture being provided by Esko’s Imaging Engine. One of the benefits of an extended color gamut is that printers are spared the constant wash-ups which accompany the use of spot colors. Job changeover processes are accelerated and extra production time is gained.

A growing number of brand owners are today opting for an extended color gamut as an alternative to company- or product-specific spot colors. It is thus all the more important for both companies to present practically integrated prepress and print solutions which meet the highest quality standards. A wider gamut alone is not sufficient; for the overall process, the absolute stability of all relevant parameters in print is also imperative. With its advanced measuring and control systems, Koenig & Bauer offers ideal prerequisites for a stable process even over

long runs and for repeat jobs.

Packaging printers visiting the Koenig & Bauer customer center can in future not only become acquainted with the latest print and finishing technologies, but also obtain a more comprehensive overview of the integrated process and the range of workflow solutions for packaging production. Esko will likewise be using the new presentation opportunities in Radebeul to inform its own customer base.